Advancements in Smart Card Manufacturing - The Rise of Automated Antenna Embedding Machines

In the fast-evolving world of smart card manufacturing, efficiency, precision, and adaptability have become key factors driving the demand for cutting-edge automation solutions. The global market for smart cards, which includes RFID payment cards, identification cards, access control cards, and telecommunications SIM cards, is projected to continue growing at a robust pace, driven by the increasing adoption of contactless payment solutions, identity verification systems, and IoT applications.

One of the latest technological innovations transforming the smart card production landscape is the Custom Auto Antenna Embedding Machine from Shenzhen Zowinda Technology Co., Ltd. This state-of-the-art machine has garnered attention for its ability to significantly enhance production efficiency, improve quality, and offer a level of flexibility previously unattainable in smart card manufacturing.

![]()

Revolutionizing Smart Card Production with Precision

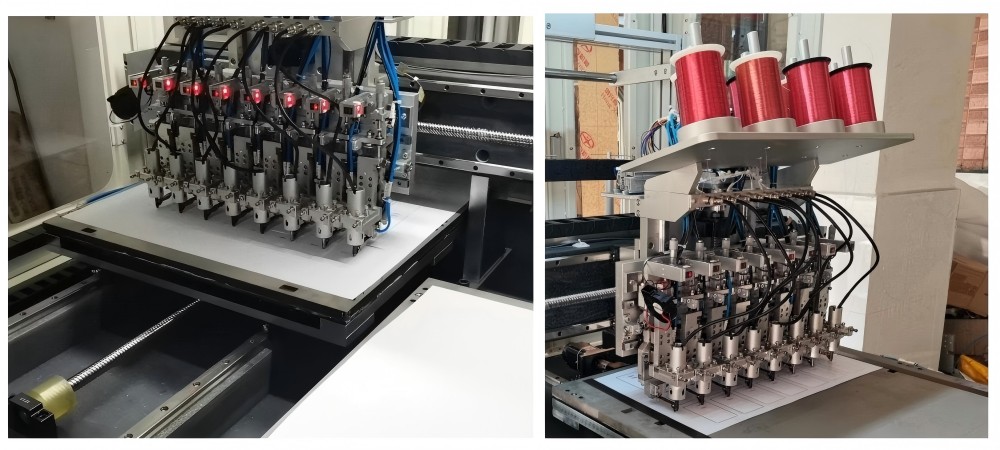

As the smart card industry faces the increasing challenge of meeting high precision and high-volume production demands, manufacturers are turning to ultrasonic technology for embedding antennas into various types of smart cards. The Custom Auto Antenna Embedding Machine is designed to meet these needs by embedding antennas into smart cards with unmatched accuracy and speed.

With a production speed of 1200 antennas per hour, the machine supports the high-throughput demands of modern manufacturers, ensuring fast turnaround times while maintaining consistent quality. Additionally, its vacuum aspirating platform guarantees precise placement of antennas, an essential feature for smart cards where antenna functionality and durability directly impact performance.

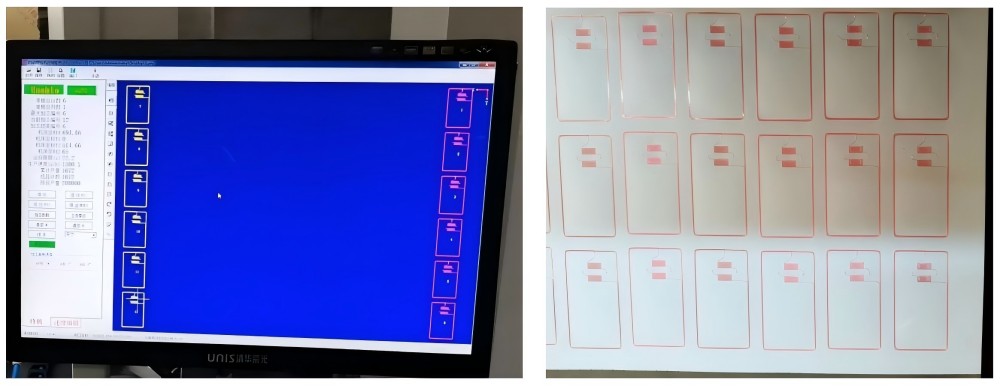

The PC-controlled automation system incorporated into the machine allows manufacturers to customize antenna designs for different smart card configurations without additional setup time. This ability to quickly adapt to changing production needs is crucial in today’s competitive market, where time-to-market can significantly affect a company’s profitability and market position.

Key Applications Driving Market Growth

The rise of contactless payment systems, access control systems, and telecommunications cards is pushing demand for precision antenna embedding solutions. Some of the key industries benefiting from the Custom Auto Antenna Embedding Machine include:

RFID Payment Cards: As digital payments become increasingly prevalent worldwide, the demand for RFID-enabled payment cards has surged. The precise embedding of antennas is crucial to ensuring reliable data transfer, making the Custom Auto Antenna Embedding Machine a critical component in the production of these cards.

Identification and Security Cards: With heightened concerns over security and identity theft, the need for secure access control cards and ID cards is on the rise. Accurate antenna embedding is vital for enabling seamless integration with security systems, ensuring the reliable functioning of access points, gates, and verification systems.

Healthcare Cards: The healthcare sector is also embracing the benefits of smart cards for patient identification and medical records management. Accurate antenna placement is essential for ensuring that these cards work seamlessly within medical systems, offering enhanced safety and security for patient data.

Telecommunications Cards: The telecom sector relies heavily on SIM cards and other types of telecommunications cards that require low-power antenna designs. The Custom Auto Antenna Embedding Machine meets these needs by embedding antennas with precision, supporting applications that require high-frequency performance.

Meeting the Demand for Flexibility and Scalability

With smart card applications expanding globally, the demand for flexible, scalable production solutions is at an all-time high. The modular design of the Custom Auto Antenna Embedding Machine makes it easy for manufacturers to adjust production capacity based on market demands. This is particularly beneficial in industries such as telecommunications and security, where order volumes can fluctuate rapidly.

Manufacturers can now benefit from the machine's ability to adapt to small-batch production for custom or niche card designs, as well as to high-volume production runs for large-scale orders. This flexibility enables manufacturers to better serve a wider range of customer needs without the need for significant investment in multiple machines.

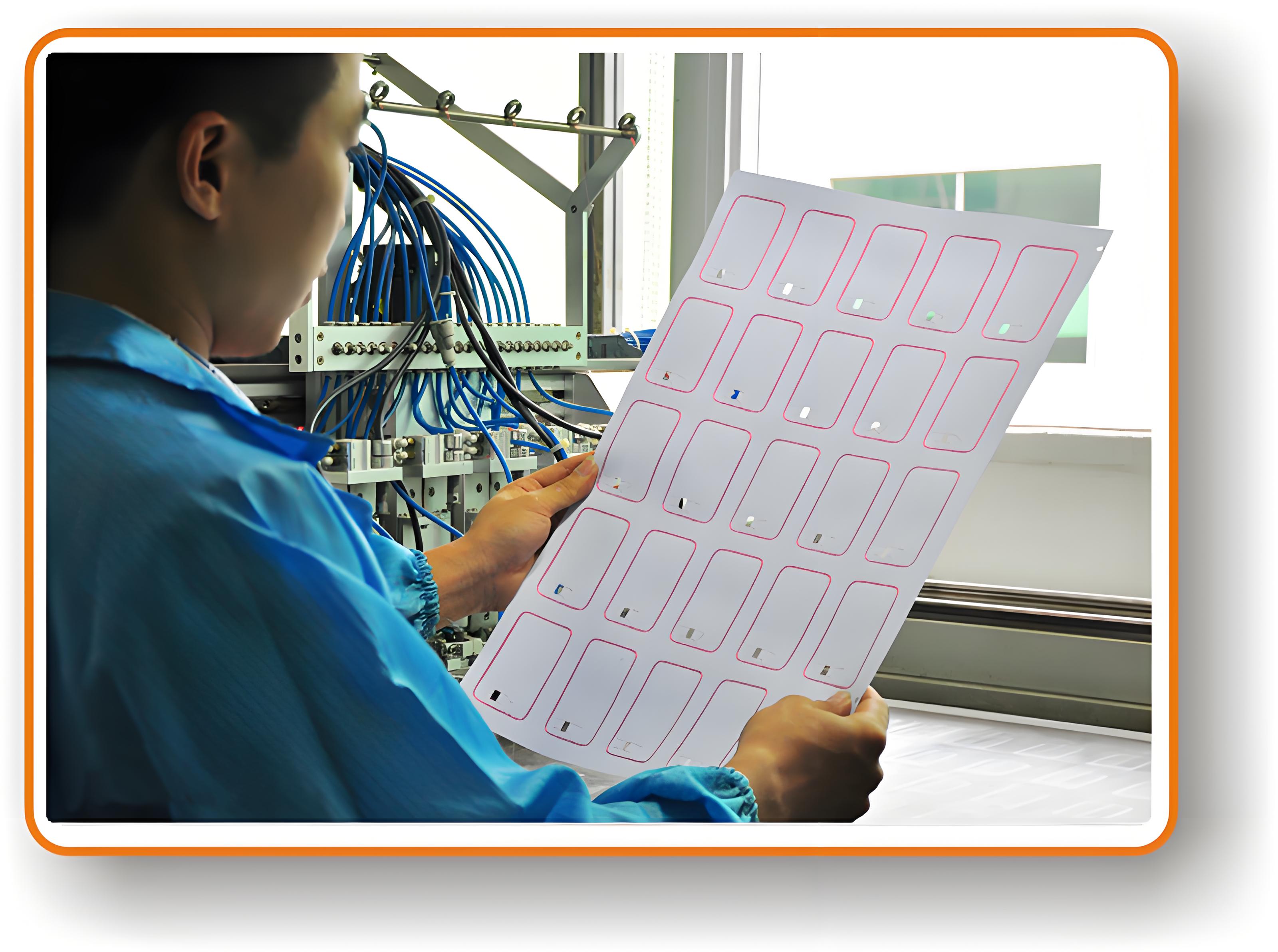

Enhancing Quality Control in Smart Card Production

The rise in demand for contactless cards and other RFID-enabled products has put pressure on manufacturers to ensure that each card meets industry standards for functionality and reliability. The Custom Auto Antenna Embedding Machine is designed to reduce defects and improve the overall quality control process in production.

By utilizing advanced ultrasonic embedding technology, the machine ensures consistent antenna placement, reducing errors associated with manual labor or less sophisticated machines. This precision is especially critical in industries like payment cards and ID cards, where any antenna misalignment could result in card malfunction or compromised security.

Market Outlook and Industry Trends

The global market for smart cards is expected to grow significantly in the coming years. As digital payments, identity verification systems, and IoT technologies continue to gain traction, the demand for high-quality, reliable smart cards will drive investment in automation solutions like the Custom Auto Antenna Embedding Machine.

RFID and Contactless Payments: The growing preference for contactless payments worldwide is expected to continue driving demand for RFID-enabled cards. As the market for RFID payment cards expands, manufacturers will need more efficient and reliable production solutions, making antenna embedding technology a critical part of the process.

Security and Privacy Concerns: As security remains a primary concern for both consumers and businesses, there is an increasing need for ID cards and access control cards that meet stringent security standards. The machine's precision antenna embedding plays a crucial role in ensuring card security and integrity.

Sustainability: With an increasing focus on sustainable production practices, manufacturers are looking for ways to enhance efficiency and reduce waste in the production of smart cards. The high-throughput capabilities of the Custom Auto Antenna Embedding Machine support these sustainability goals by optimizing production time and minimizing errors, which ultimately helps reduce material waste.

Conclusion: A Game-Changer for Smart Card Manufacturers

The Custom Auto Antenna Embedding Machine represents a significant advancement in the manufacturing of smart cards, offering unmatched precision, flexibility, and scalability. As industries like RFID payments, access control, and telecommunications continue to grow, this innovative solution will help manufacturers meet the increasing demand for high-quality smart cards while enhancing operational efficiency.

For smart card manufacturers looking to stay ahead of the curve, investing in the Custom Auto Antenna Embedding Machine is a strategic move that promises both short-term and long-term benefits, ensuring the production of reliable, secure, and efficient smart cards that meet the demands of the global market.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.