Revolutionizing RFID and Contactless Card Production with the Auto Antenna Embedding Machine

Increased Demand for Smart Cards and RFID Technology Drives the Need for Advanced Manufacturing Solutions

As the global demand for contactless cards, RFID technology, and smart card applications continues to soar, manufacturers are under increasing pressure to streamline production while maintaining high-quality standards. From secure payment solutions to smart identification, access control, and asset tracking, the need for faster, more reliable card production methods has never been more critical. To meet this growing demand, advanced manufacturing equipment is playing a pivotal role in transforming the industry.

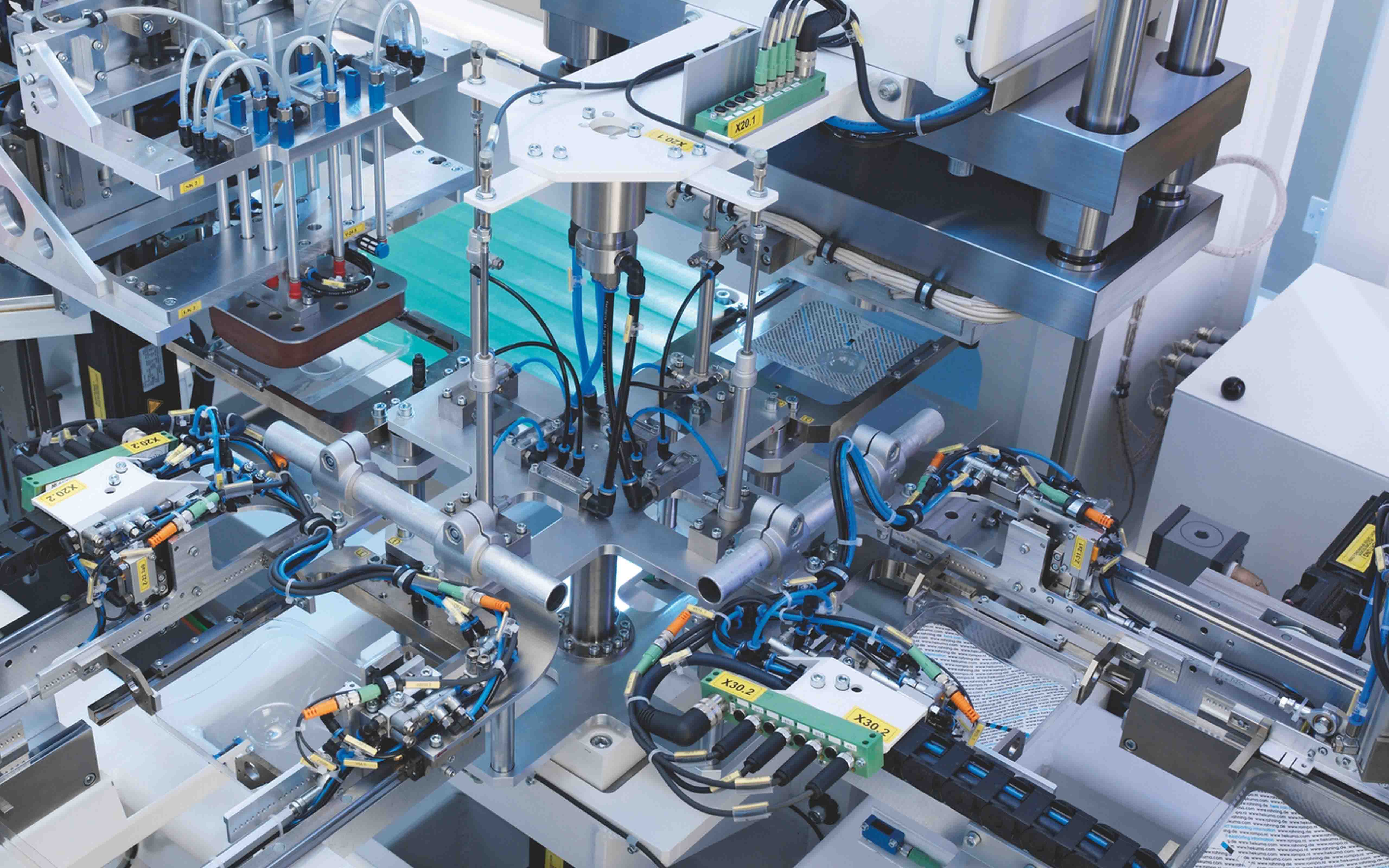

One such breakthrough in automation technology is the Auto Antenna Embedding Machine, a state-of-the-art solution designed to streamline and optimize the process of embedding antennas onto inlay sheets for RFID and smart cards. This machine is rapidly becoming a game-changer for manufacturers in the RFID, contactless payment, and smart card sectors, helping businesses meet both production volume and precision requirements.

The Rise of RFID and Smart Cards

In recent years, RFID technology has become ubiquitous, from retail and logistics to secure access control and public transportation. The global RFID market is expected to continue expanding, with an increasing number of industries adopting RFID for its efficiency and security features. Similarly, contactless cards are replacing traditional magnetic stripe cards in numerous applications, thanks to their enhanced security and faster transaction speeds.

As this shift to RFID and smart cards accelerates, manufacturers must find ways to keep up with the escalating production demands while ensuring consistent quality control. A key challenge for many manufacturers is the precision required in embedding antennas onto inlay sheets, as this directly impacts the performance and reliability of the final product.

Introducing the Auto Antenna Embedding Machine

The Auto Antenna Embedding Machine offers a revolutionary solution to this challenge. Equipped with cutting-edge ultrasonic embedding technology, this machine guarantees precise and consistent antenna placement onto inlay sheets—ensuring that each card meets rigorous performance standards. The machine’s dual vacuum platens enhance productivity by allowing continuous production without stopping for material changes, increasing uptime and efficiency.

The machine’s PC control system makes it easy to adapt to a wide range of antenna shapes, sizes, and sheet layouts, offering unmatched flexibility. Its high-speed operation—capable of embedding up to 400 antennas per hour—is especially beneficial for manufacturers handling high-volume production.

Key Features Meeting Industry Needs

1.High Precision: Using ultrasonic embedding technology, the machine ensures high-quality antenna attachment to the inlay sheet, ensuring that each card meets the performance standards required for RFID and smart card applications.

2.Flexibility: The PC-controlled system with professional drawing software allows for easy programming and customization of antenna paths, making the machine adaptable to different antenna geometries and layouts, without the need for additional tooling.

3.High-Speed Production: With the ability to embed 400 antennas per hour, this machine accelerates production, helping manufacturers keep up with the growing demand for RFID cards and contactless cards.

4.Reduced Downtime: The dual vacuum platens allow the machine to operate continuously, improving efficiency and output, while minimizing downtime associated with material changes.

5.User-Friendly Interface: The machine’s wide LCD touch screen interface provides an intuitive user experience, allowing operators to easily monitor and adjust settings.

Applications Across Industries

The Auto Antenna Embedding Machine is already making significant strides in various industries where RFID and contactless cards are becoming increasingly essential. Some of the key applications include:

Contactless Card Manufacturing: The machine is perfect for embedding antennas in contactless payment cards, ID verification cards, and access control cards, helping to enhance security and user experience in these high-demand applications.

RFID Card Production: From asset tracking to logistics management, the machine is highly effective for embedding antennas in RFID cards and tags used in supply chain management, inventory control, and logistics.

Smart Card Production: With its high precision and speed, the Auto Antenna Embedding Machine is ideal for embedding antennas in smart cards used in applications such as healthcare, banking, and public transportation.

The Future of Card Manufacturing

As the demand for contactless cards, RFID, and smart cards continues to rise, manufacturers must adopt automation solutions that can scale with these demands while maintaining the highest quality standards. The Auto Antenna Embedding Machine offers a comprehensive solution for efficient, high-precision production, helping manufacturers meet the increasing needs of the global market.

In an era where speed, precision, and efficiency are crucial for staying competitive, the Auto Antenna Embedding Machine is poised to be a critical asset for businesses in the RFID and card manufacturing sectors. By leveraging this advanced technology, manufacturers can significantly reduce costs, improve productivity, and deliver high-quality products that meet the demands of the ever-evolving contactless and RFID card market.

This machine’s advanced features, customizability, and efficiency are revolutionizing the card manufacturing industry, empowering businesses to scale production while keeping up with the fast-paced demands of the RFID and contactless card markets. As businesses continue to adopt smart solutions for card production, the Auto Antenna Embedding Machine is positioning itself as a leading tool for ensuring consistent, high-quality, and cost-effective manufacturing.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.