Breakthrough in Smart Card Production: The Rise of the Auto Glue Tape Lamination Machine

In a rapidly evolving market for contactless cards and smart cards, manufacturers are constantly seeking ways to increase production efficiency while maintaining the highest standards of quality. One of the latest innovations making waves in the smart card manufacturing industry is the introduction of the Auto Glue Tape Lamination Machine.

A Game-Changer for Smart Card Production

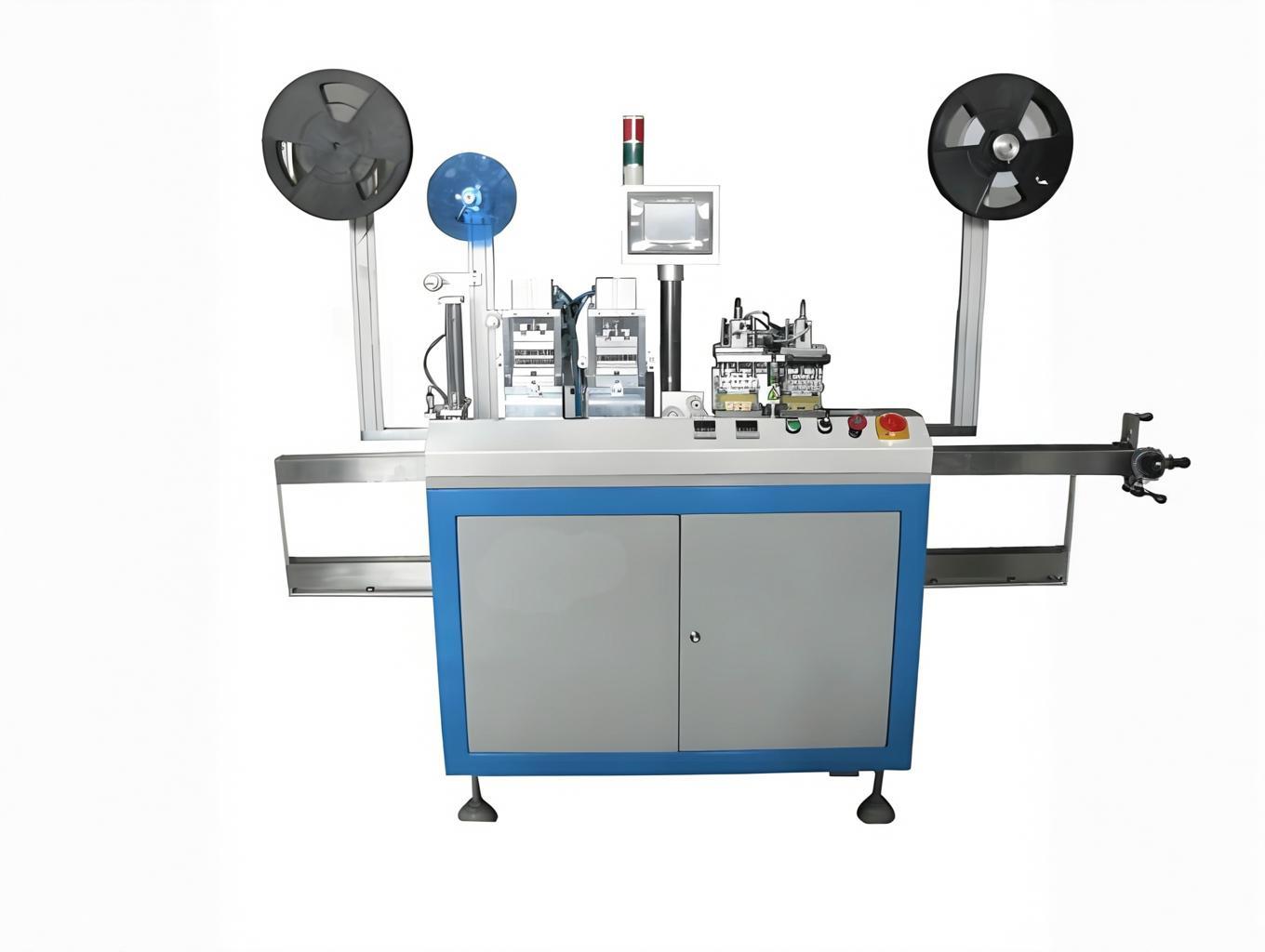

The Auto Glue Tape Lamination Machine is transforming the way manufacturers approach the lamination process of IC modules used in smart cards, RFID cards, and other contactless solutions. By automating the gluing process with hot melt adhesive tape, this advanced machine offers high-speed production rates of up to 15,000 chips per hour.

Equipped with PLC automatic control and a touch screen interface, the machine provides precise control over the lamination parameters, offering flexibility for manufacturers to adjust settings quickly without compromising on efficiency. The servo-controlled system ensures that every IC module is securely laminated with precision, enhancing the durability and reliability of the finished cards.

Key Advantages in the Production Process

The introduction of this machine comes at a critical time when the demand for contactless payment cards, ID cards, and access control systems is increasing globally. Here are some key advantages it brings to the industry:

1.Speed and Efficiency: The machine operates at an impressive speed of 11,000 to 15,000 chips per hour, significantly reducing production time and boosting throughput, making it ideal for high-volume manufacturers.

2.Flexibility and Versatility: This machine can handle a variety of IC module sizes, including 6-pin and 8-pin configurations, without the need for mold changes. The flexibility to easily switch between different models without additional setup makes it a versatile tool in any production line.

3.Advanced Control System: The machine’s PLC system and user-friendly interface ensure easy operation, while servo motors provide precision in controlling the movement of the materials, making it easier to manage both small and large-scale production runs.

4.Cost-Effectiveness: By automating the lamination process, manufacturers can reduce labor costs, minimize errors, and maintain consistent quality, leading to lower overall production costs.

Meeting the Growing Demand for Contactless Cards

As the global demand for contactless payment solutions and smart cards continues to rise, companies are under increasing pressure to enhance their manufacturing capabilities. The Auto Glue Tape Lamination Machine addresses this challenge head-on by improving both production efficiency and card quality.

With industries ranging from banking and telecommunications to security and transportation increasingly relying on contactless technology, manufacturers are investing heavily in automation equipment like this machine to stay competitive.

Applications Across Various Industries

This new machine is not just limited to contactless payment cards. It also plays a vital role in the production of access control cards, identification cards, membership cards, and public transportation passes. Its ability to handle a variety of IC modules with different designs makes it a key player in multiple sectors.

Contactless card manufacturers, in particular, stand to benefit greatly from this innovation, as it significantly reduces production time, improves consistency, and boosts output.

The Future of Smart Card Manufacturing

As the smart card industry continues to grow, manufacturers must find ways to meet the increasing demands for high-quality, high-speed production. The Auto Glue Tape Lamination Machine is set to become a cornerstone of future card production lines, offering advanced capabilities that provide manufacturers with the competitive edge they need.

For businesses looking to invest in cutting-edge technology to streamline their production processes, the Auto Glue Tape Lamination Machine represents a game-changing solution in the fast-paced world of smart card manufacturing.

In conclusion, the Auto Glue Tape Lamination Machine is helping companies scale production without sacrificing quality, ensuring that they remain ahead of the curve in a rapidly changing market.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.