Zowinda Launches RFID Automatic Flip-Chip System to Enhance RFID Tag Production Efficiency and Precision

With the widespread application of RFID technology in logistics, retail, and manufacturing, Zowinda Technology Co., Ltd. has announced the launch of its latest RFID Automatic Flip-Chip System, providing a highly efficient, precise, and fully automated solution for RFID tag production. The system achieves an impressive 99.5% yield rate, helping companies significantly improve RFID tag production efficiency and meet the growing demand for high-performance RFID solutions.

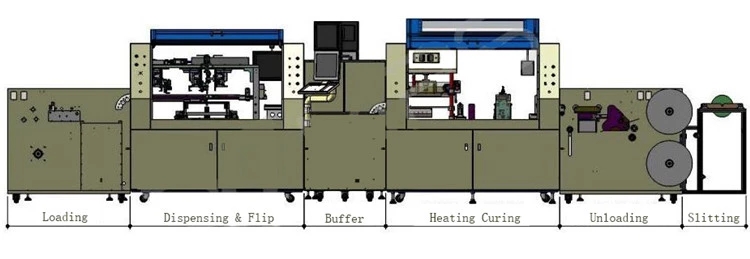

The RFID Automatic Flip-Chip System integrates several advanced modules into a single platform, including antenna web handling, epoxy jetting, flip-chip placement, final curing, and testing. This comprehensive design ensures streamlined operations, reducing labor costs and improving production speeds. The system is capable of processing all types of HF (High Frequency) and UHF (Ultra High Frequency) RFID inlays, offering versatility for various industries.

Key Features of the RFID Automatic Flip-Chip System:

- High Speed and Precision: With a throughput of up to 8500 units per hour (UPH), this system provides excellent bonding accuracy of ±30μm, ensuring optimal performance for high-quality RFID tags.

- Fully Automated Process: The system includes multiple modules such as loading, dispensing, flip-chip placement, visual inspection, curing, testing, and unloading, all managed by a central control system for seamless operations.

- Versatility: Compatible with 8" and 12" wafers and capable of processing chips ranging from 0.4mm to 2.0mm, the system can accommodate a variety of RFID tag requirements.

Modular Design: The system features a modular design for easy scalability, making it ideal for high-volume production and flexible enough for future upgrades.

Advanced Components and Specifications:

- High-Speed Camera: Equipped with a Basler high-speed camera for accurate visual inspection and alignment.

- Servo Motors: Powered by 33 Panasonic servo motors for high-precision operations.

- Heating and Curing: Features a heating curing module to ensure proper chip bonding, with controlled vacuum pressure and compressed air for optimal curing conditions.

User Interface: Includes a Weinview touch screen for easy operation and control, reducing operator training time.

Technical Specifications:

- Dimensions: 7300mm * 1500mm * 1560mm

- Weight: 4500kg

- Bonding Speed: 8500 UPH (dependent on antenna layout)

- Bonding Accuracy: ±30μm

- Wafer Dimensions: 8", 12"

- Chip Size: 0.4mm ~ 2.0mm

- Compressed Air Pressure: 0.45Mpa ~ 0.6Mpa

- Vacuum Pressure: -80Kpa ~ -100Kpa

Material Bandwidth: 100mm ~ 370mm

Transforming RFID Tag Production

With the global RFID market expanding rapidly, especially in industries such as supply chain management, asset tracking, and smart retail, Zowinda’s RFID Automatic Flip-Chip System promises to provide manufacturers with a state-of-the-art solution to meet market demands. By streamlining production and improving the precision and efficiency of RFID tag manufacturing, Zowinda is well-positioned to help companies achieve faster production times, reduce waste, and ultimately improve their bottom line.

Conclusion

Zowinda’s RFID Automatic Flip-Chip System is the ideal solution for companies looking to enhance the efficiency, precision, and scalability of their RFID tag production processes. With its fully integrated system design, high-speed performance, and industry-leading accuracy, it is set to become a key player in the rapidly growing RFID market.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.