Zowinda Unveils Cutting-Edge Automatic Sheet Collating and Overlay Machine for High-Precision Card Production

Zowinda Technology Co., Ltd., a leading provider of high-tech card production solutions, has introduced its groundbreaking Automatic Sheet Collating and Overlay Machine. This advanced system is designed to meet the demanding needs of modern card-based production, offering automated precision and efficiency that enhances overall manufacturing capabilities for businesses in industries such as banking, government, and membership card production.

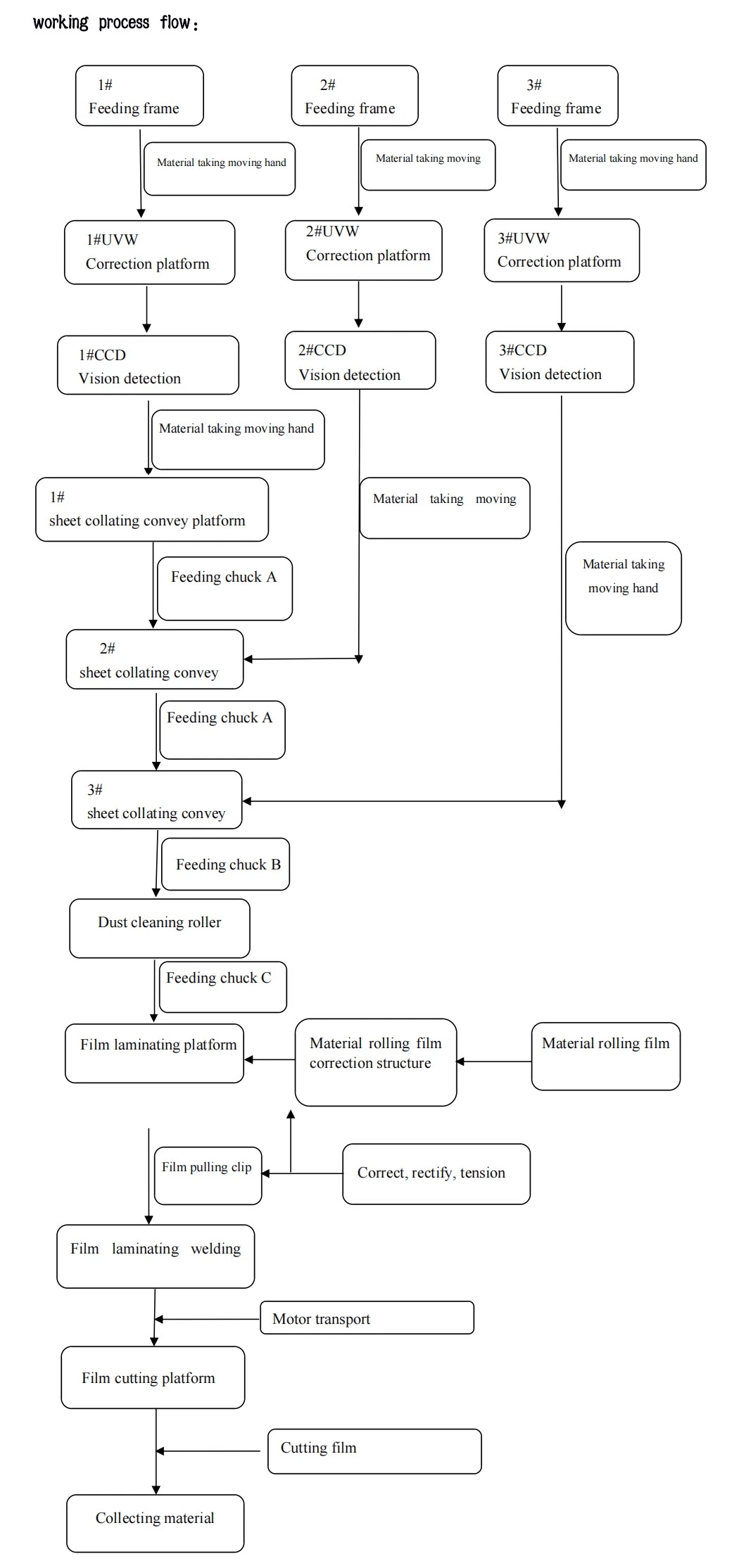

With the growing demand for personalized, high-quality cards, Zowinda’s new machine promises to revolutionize the card production process by automating key steps such as sheet loading, collating, overlay laminating, ultrasonic welding, material correction, and card cutting. This integration of multiple processes into one system platform provides a seamless production flow, ensuring faster, more accurate, and cost-effective operations.

Key Features Driving the Innovation in Card Production

1.Automatic PVC Sheet Loading & Collating

The machine incorporates advanced feeding frames that seamlessly load and separate PVC sheets, while the high-precision cross roller platforms and step motors correct material alignment in both X and Y directions, ensuring perfect registration for the next process.

2.Advanced CCD Vision and Color Code Detection

The integrated CCD vision system with a color code magic eye continuously monitors material positioning, making real-time adjustments to guarantee perfect alignment for lamination and welding processes.

3.Precision Ultrasonic Welding & Laminating

With ultrasonic welding technology, the machine ensures strong, precise bonding of card layers, and the automatic laminating system applies high-quality film for flawless card production. After lamination, the film is precisely cut with servo-driven mechanisms, ensuring minimal waste.

4.Dust Removal & Material Correction

Prior to processing, the machine utilizes sticky dust rollers to eliminate any unwanted dust particles from the PVC sheets, ensuring that the bonding and welding processes produce optimal results.

5.High Efficiency and Output

The machine can produce between 700-900 cards per hour, making it ideal for high-volume manufacturing lines. With a collating accuracy of ±0.1mm, this machine ensures high consistency and superior quality for each card produced.

Versatility and Application Across Industries

Zowinda’s Automatic Sheet Collating and Overlay Machine is perfect for a wide range of applications in the card production industry:

- Bank Cards: The system is ideal for producing bank cards, offering precise lamination, cutting, and personalization for high-end, secure banking products.

- ID Cards: Perfect for government agencies and security applications, ensuring card integrity and durability.

- Membership & Gift Cards: The machine is well-suited for large-volume production of membership and gift cards, combining speed with accuracy.

Smart Cards: With the capacity to handle RFID and contactless cards, the system supports the advanced needs of the evolving smart card industry.

Boosting Production Efficiency and Quality

The Automatic Sheet Collating and Overlay Machine is designed to streamline card production lines, increasing efficiency, reducing manual labor, and improving overall precision. With a highly flexible configuration, it supports multiple card formats, including 3x8, 4x8, and 5x5, making it adaptable to a wide variety of production needs.

With servo motor-driven systems, CCD vision positioning, and automated feedback mechanisms, the machine adapts to material variations, ensuring stable, high-quality production in fast-paced, high-demand environments.

Conclusion: A Game-Changer in Card Production

Zowinda’s innovative solution is set to transform card manufacturing, enabling companies to meet increasing demand for personalized, high-quality cards while improving production efficiency. Whether you’re producing PVC, PETG, or paper cards, the Automatic Sheet Collating and Overlay Machine is a comprehensive solution for the card production industry, offering fast, reliable, and cost-effective automation for modern production lines.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.