Revolutionizing Electronics Assembly with the Auto COB Pick and Placer Machine

In the fast-paced world of electronics manufacturing, precision, speed, and efficiency are the driving forces behind production success. The growing demand for high-quality electronic devices, coupled with the need to streamline production processes, has led to the development of advanced automated solutions. One such innovation transforming the industry is the Auto COB Pick and Placer Machine, a cutting-edge technology that is setting new standards in Chip-On-Board (COB) placement.

Rising Demand for High-Precision Electronics Manufacturing

As consumer electronics and smart devices continue to evolve, manufacturers face increasing pressure to deliver smaller, faster, and more powerful products at competitive prices. A critical aspect of this challenge is the assembly of printed circuit boards (PCBs), where precision and speed are non-negotiable. COB technology, which involves directly mounting chips onto a substrate without the use of additional packaging, is becoming the go-to solution for many manufacturers. However, manual placement of COB chips can be time-consuming and prone to errors, underscoring the need for a reliable automated solution.

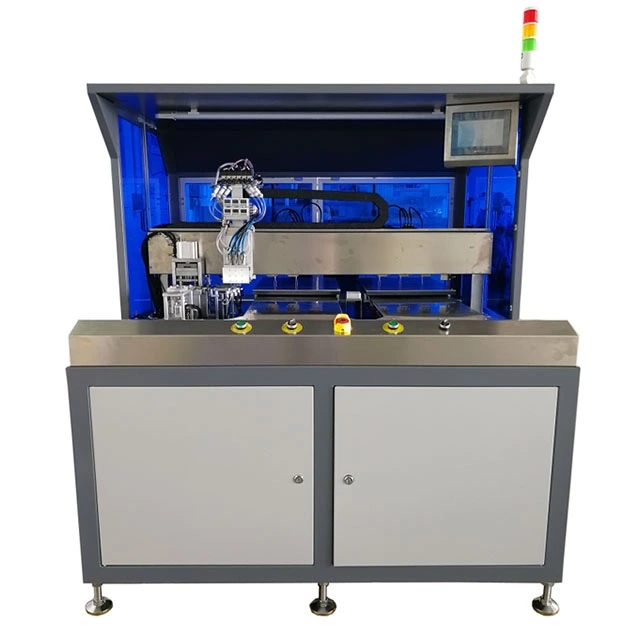

The APP-3000: A Game-Changer for Electronics Assembly

Enter the Auto COB Pick and Placer Machine. Designed specifically to automate the COB placement process, this advanced machine offers several advantages that help manufacturers stay competitive in a rapidly evolving market.

1. Unmatched Speed and Precision:

The APP-3000 is capable of placing up to 4000 PCS per hour, significantly improving production throughput. This high-speed performance is coupled with ±0.05mm positioning accuracy, ensuring that each chip is placed precisely, reducing the risk of defects and increasing the quality of the final product.

2. Versatile Layout Options:

One of the standout features of the APP-3000 is its ability to adapt to different production requirements. The machine supports multiple layout options, including 3x7 and 3x8 configurations, making it easy to switch between formats. The flexibility of the machine allows manufacturers to quickly adjust to varying project demands without the need for additional equipment or downtime.

3. Integrated Glue Dispensing:

In addition to its precise pick-and-place function, the APP-3000 includes six integrated glue dispensing units that work concurrently with the placement process. This simultaneous operation reduces downtime, enhances productivity, and ensures consistent application of glue for secure chip mounting.

4. User-Friendly Interface and Smart Monitoring:

Manufacturers need not worry about complicated operations. The intuitive touch-screen interface of the APP-3000 makes it easy for operators to set up and manage the machine. Additionally, the machine features intelligent monitoring systems that alert operators to irregularities, ensuring that any potential issues are addressed immediately.

5. Robust Construction and Durability:

The APP-3000 is designed to handle the demands of high-volume production environments. Its robust construction ensures that it can withstand continuous operation, making it a long-term investment for any electronics assembly line.

Meeting Market Demand for Efficiency

In today's competitive electronics market, automation is no longer just a luxury—it's a necessity. Companies that invest in automated systems like the Auto COB Pick and Placer Machine are positioning themselves to meet the growing demand for precision, speed, and efficiency in manufacturing.

The global market for automated electronics assembly is expected to continue growing, driven by factors such as the expansion of the Internet of Things (IoT), 5G technology, and the growing need for miniaturized electronic devices. As these trends continue, the demand for high-speed, accurate, and efficient COB placement will only increase. The APP-3000, with its advanced features and capabilities, offers manufacturers the tools they need to stay ahead in this fast-moving market.

The Future of Electronics Manufacturing: Embracing Innovation

As the electronics industry moves toward more automated, scalable, and efficient solutions, the Auto COB Pick and Placer Machine is poised to play a central role. Manufacturers that embrace these cutting-edge technologies will not only improve their operational efficiency but also drive innovation in product development.

In a market where time-to-market is a critical factor, the APP-3000’s ability to increase production speed while maintaining quality and precision will be invaluable for companies striving to meet the evolving demands of the electronics industry.

Conclusion: A Key Investment for Future-Proof Manufacturing

The Auto COB Pick and Placer Machine is more than just a tool for placing chips; it’s a transformative piece of equipment that empowers manufacturers to enhance their production capabilities, improve product quality, and remain competitive in an increasingly automated world. With its precision, speed, and advanced features, the APP-3000 is helping to define the future of electronics assembly.

Manufacturers seeking to optimize their production lines and reduce costs while maintaining the highest standards of quality should look no further than the Auto COB Pick and Placer Machine—a smart investment for the future of electronics manufacturing.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.