Revolutionizing Card Production: The Rise of Automatic Sheet Collating and Overlay Laminating Machines

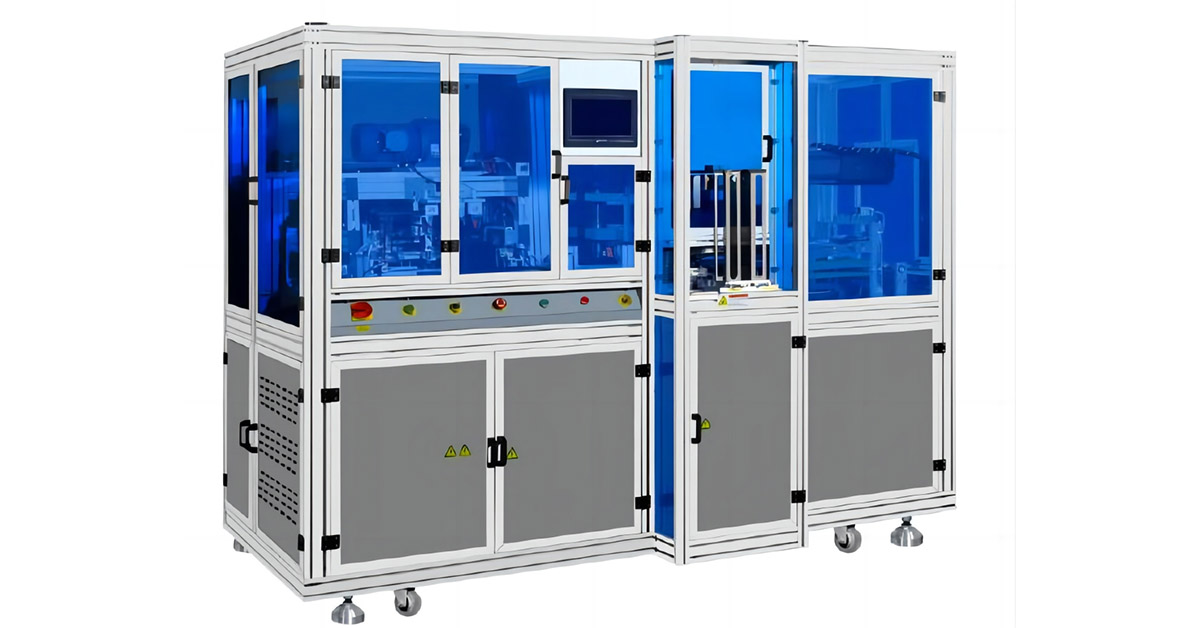

In the fast-paced world of card manufacturing, efficiency, precision, and automation are key drivers for success. As industries demand higher production rates and more complex designs, manufacturers are increasingly turning to cutting-edge technology to keep up with the competition. One such innovation transforming the card production sector is the Automatic Sheet Collating and Overlay Laminating Machine.

This advanced piece of equipment promises to elevate production capabilities by seamlessly integrating multiple processes, including auto sheet loading, sheet collating, overlay laminating, and cutting. As global markets continue to prioritize automation, the demand for such high-efficiency machines has soared, offering both improved output and reduced human error. Let’s explore how this technology is reshaping the future of card-based production.

Streamlining Card Production with Advanced Automation

In the traditional card production process, handling multiple layers of materials, aligning sheets accurately, and applying overlays were time-consuming tasks that required meticulous manual labor. With the introduction of the Automatic Sheet Collating and Overlay Laminating Machine, these operations are now automated, significantly reducing the need for manual intervention. The machine integrates the critical processes of sheet loading, material correction, collating, overlay laminating, and cutting, all in a seamless flow.

The system uses an innovative CCD vision system, which works in tandem with color code detection to ensure the precise alignment of materials. This results in highly accurate sheet collating and overlay laminating, a major improvement over traditional methods that often faced challenges in material positioning and alignment. With a collating accuracy of ±0.1mm, the machine ensures consistency across all batches, producing high-quality cards with minimal waste.

Increased Efficiency and Production Speed

The need for speed in manufacturing has never been greater, and the Automatic Sheet Collating and Overlay Laminating Machine delivers. Capable of producing 700-900 units per hour, this machine significantly boosts throughput compared to traditional manual processes. By automating processes that were previously time-consuming, manufacturers can meet increasing demand without sacrificing quality.

In a competitive marketplace where time-to-market is critical, being able to quickly scale production is an invaluable advantage. The ability to handle large volumes without compromising on precision allows manufacturers to stay ahead of the curve, especially in industries like financial services, loyalty card production, and smartcard manufacturing, where high precision is a necessity.

Enhanced Precision and Versatility

A standout feature of this machine is its versatility in handling a range of materials, from PVC to PET. The inclusion of ultrasonic welding for the overlay laminating process further enhances the machine's performance. This ensures that the overlay is applied seamlessly, with high precision, without the risk of shifting during the lamination or welding process.

Furthermore, the machine’s design incorporates multiple feeding platforms and servo system controls, which adjust the material position automatically to ensure correct alignment. This precision ensures that each card is produced with consistency and quality, offering manufacturers the confidence that their products meet the highest standards.

Market Trends Driving Automation in Card Manufacturing

As the card manufacturing industry evolves, the trend toward automation is clear. Companies are increasingly recognizing the need for machines that can handle multiple tasks, reduce human error, and improve production speeds. The global market for card manufacturing equipment is growing steadily, driven by the rise of smartcards, bank cards, ID cards, and other personal identification products.

Moreover, automation helps manufacturers address the growing need for customization and personalization. Cards now come in a variety of shapes, sizes, and materials, with custom designs and security features. This requires equipment that is flexible enough to handle different production demands while maintaining high throughput.

The Automatic Sheet Collating and Overlay Laminating Machine is poised to be a key player in this transformation. It not only enhances production speed but also offers customization capabilities, allowing manufacturers to produce cards with varying designs and functionalities to meet the unique needs of their customers.

The Future of Card Production: Efficiency, Quality, and Innovation

Looking ahead, the card production industry is set to become even more automated and efficient. With the integration of technologies like AI, machine learning, and IoT, future machines will be able to predict maintenance needs, optimize production schedules, and adapt in real time to changing production requirements. These advancements will allow manufacturers to continue increasing efficiency while further reducing costs.

The Automatic Sheet Collating and Overlay Laminating Machine is a critical step in this journey, providing manufacturers with the tools they need to produce high-quality cards faster and more efficiently. By automating key processes, this machine is helping manufacturers remain competitive in an increasingly demanding global market.

As demand for smart cards, membership cards, and gift cards continues to rise, the need for reliable, high-efficiency production systems will only increase. With solutions like the Automatic Sheet Collating and Overlay Laminating Machine, manufacturers are well-positioned to meet these challenges head-on, offering products that combine speed, precision, and quality.

Conclusion

The Automatic Sheet Collating and Overlay Laminating Machine is more than just an innovation in card production—it is a game-changer for the industry. By combining precision, automation, and versatility, it’s poised to set new standards in manufacturing efficiency and quality. For manufacturers looking to scale their operations and stay competitive in the ever-evolving card production market, embracing this technology is a step toward the future.

As automation continues to redefine the production landscape, machines like the Automatic Sheet Collating and Overlay Laminating Machine will play a crucial role in driving innovation, enhancing productivity, and meeting the growing demand for high-quality, custom-designed cards.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.