Revolutionizing Card Production with the AUTO Bonding Machine

As demand for contactless and smart card technologies continues to rise globally, manufacturers are increasingly seeking solutions that not only meet the growing production volumes but also ensure high-quality output and operational efficiency. In response to this demand, the AUTO Bonding Machine has emerged as a groundbreaking solution for the card manufacturing industry, transforming how antennas and modules are welded in the production of contactless cards, RFID cards, and smart cards.

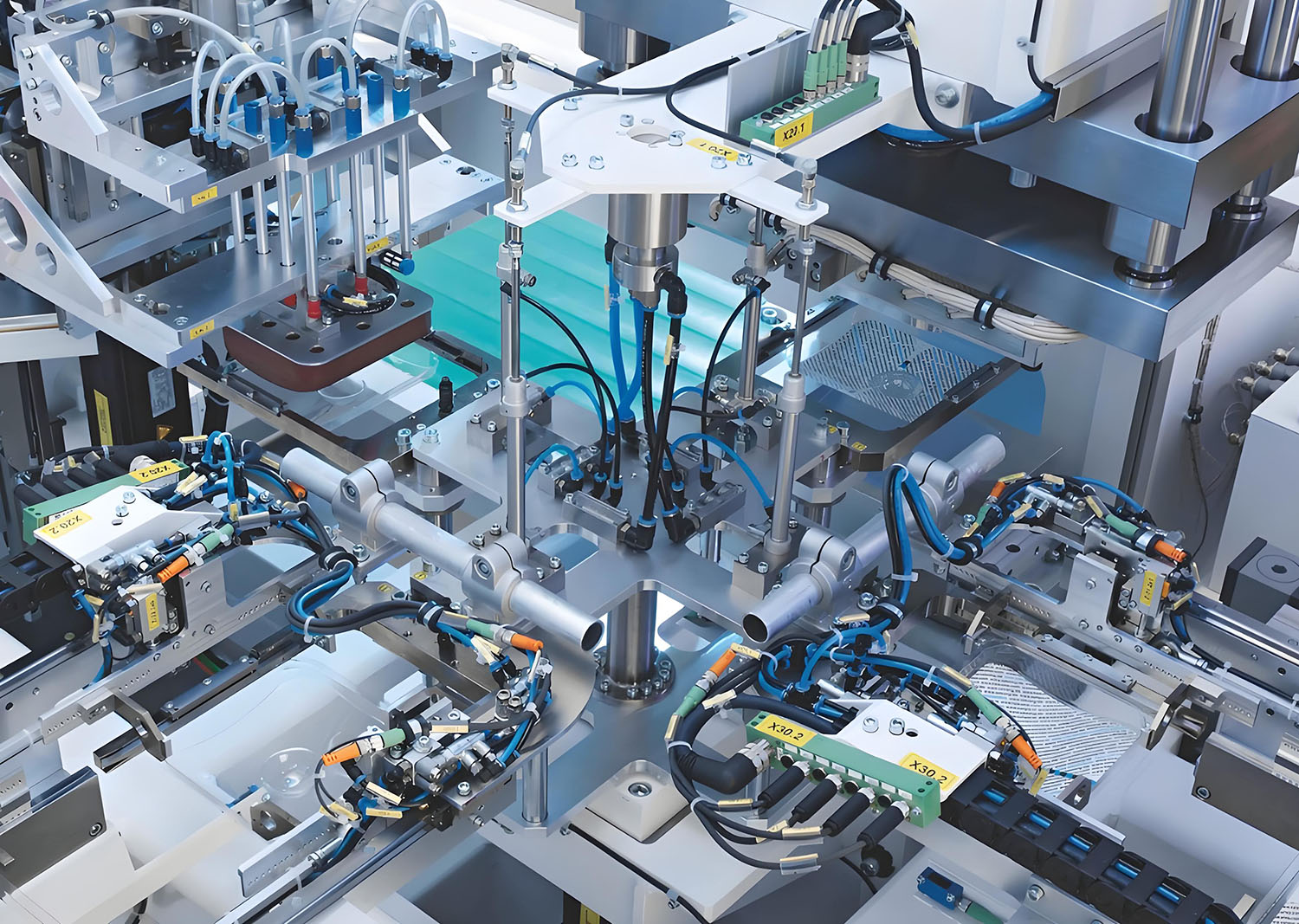

A Leap Forward in Automation and Precision

The AUTO Bonding Machine is an advanced, fully automated system designed to weld antennas and modules onto card substrates with unparalleled precision. By leveraging PLC control and a dual-axis positioning system, this machine allows for seamless adjustment of the X and Y directions, ensuring high accuracy in the welding process. This automated process reduces manual intervention, significantly lowering labor costs, and enhancing production efficiency.

What sets the AUTO Bonding Machine apart is its double pulse current inverter welding technology, which ensures both stability and speed in the welding process while maintaining the highest product quality. This technology allows manufacturers to meet the increasing demand for large-scale, high-quality production runs while minimizing downtime and defects.

Enhanced Flexibility with Multi-Head Welding

The AUTO Bonding Machine is equipped with 5 welding heads, offering significant flexibility in its operation. Depending on the production needs, manufacturers can choose to operate all five heads simultaneously or select specific heads to work independently. This capability enhances the machine's overall efficiency, allowing for rapid production without compromising on the precision of each weld.

With a production rate of 1000 to 1500 cards per hour per head, the machine is designed for high-volume applications, making it ideal for industries where speed and quality are critical, such as contactless payment cards, smart cards, and RFID tags. The ability to customize welding parameters for each position ensures that each card produced meets the highest standards, regardless of layout configuration.

Seamless Integration into Production Lines

The AUTO Bonding Machine's user-friendly interface and PLC-based control system simplify its integration into existing production lines. With a simple setup process and a wide touch interface, operators can easily control and monitor the machine's operation. The machine also offers the ability to independently adjust the parameters for each welding point, ensuring precise and customizable results.

The machine is compatible with various sheet layouts such as 3×8, 4×8, and 5×5, making it versatile for different production requirements. Additionally, its compact design and servo system control ensure smooth and reliable performance, contributing to continuous, high-quality output with minimal downtime.

Meeting the Demands of Modern Manufacturing

The AUTO Bonding Machine has been specifically engineered to meet the demands of high-speed, high-precision production environments, where even the smallest error in antenna or module placement can lead to significant defects in the final product. Its adaptability and robust performance make it ideal for industries such as RFID card manufacturing, smart card production, and contactless card assembly.

As the global shift towards cashless transactions, smart cities, and advanced identification systems continues, the demand for reliable, high-quality card manufacturing equipment is expected to grow. The AUTO Bonding Machine provides manufacturers with a cost-effective, high-speed, and flexible solution to meet this demand.

Applications of the AUTO Bonding Machine:

1.Contactless Card Manufacturing:

- Streamline the production process for contactless payment cards and access control cards, where high-speed, accurate chip placement and antenna bonding are critical.

2.Smart Card Production:

- Perfect for producing smart cards used in public transportation, healthcare, and identification systems, where precise module and antenna welding ensures functionality and durability.

3.RFID Card Manufacturing:

- Ideal for embedding antennas in RFID cards and tags used for asset tracking, security, and logistics, where precision and high throughput are essential.

4.Customization for Various Layouts:

- With compatibility for layouts like 3×8, 4×8, and 5×5, the machine is adaptable to various production needs and can handle a wide range of card designs and specifications.

Conclusion

The AUTO Bonding Machine is not just a tool; it’s a game-changer in the card manufacturing industry. By offering a high degree of automation, precision, and flexibility, it empowers manufacturers to keep up with the growing demand for contactless and smart cards while ensuring the highest standards of quality and efficiency. As the world moves toward more advanced identification and payment solutions, the AUTO Bonding Machine is poised to play a key role in shaping the future of card production.

To learn more about how the AUTO Bonding Machine can enhance your card manufacturing process, contact us for a customized consultation and product demo.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.