Innovations in Inlay Sheet Production: The Position Hole Punching Machine Revolutionizes Card Manufacturing

The global demand for contactless cards, RFID cards, and smart cards continues to surge as industries across the world adopt digital and contactless solutions. As the manufacturing process becomes increasingly complex, the need for precision and efficiency in card production has never been more critical. Enter the Position Hole Punching Machine, an advanced piece of machinery that is redefining inlay sheet production.

The Need for Precision in Card Manufacturing

Inlay sheets are a crucial component in the production of smart cards, including RFID and contactless cards used in a variety of applications, from payments to access control. The positioning of holes on these sheets, especially for fixing contactless chips, demands high precision to ensure functionality and durability. Traditional manual methods or outdated machines often result in inconsistencies and slower production speeds, leading to increased costs and production delays.

This is where the Position Hole Punching Machine steps in. By automating the punching process, this machine ensures high-speed, high-accuracy results, making it an essential tool for modern card manufacturers.

Unmatched Efficiency and Precision

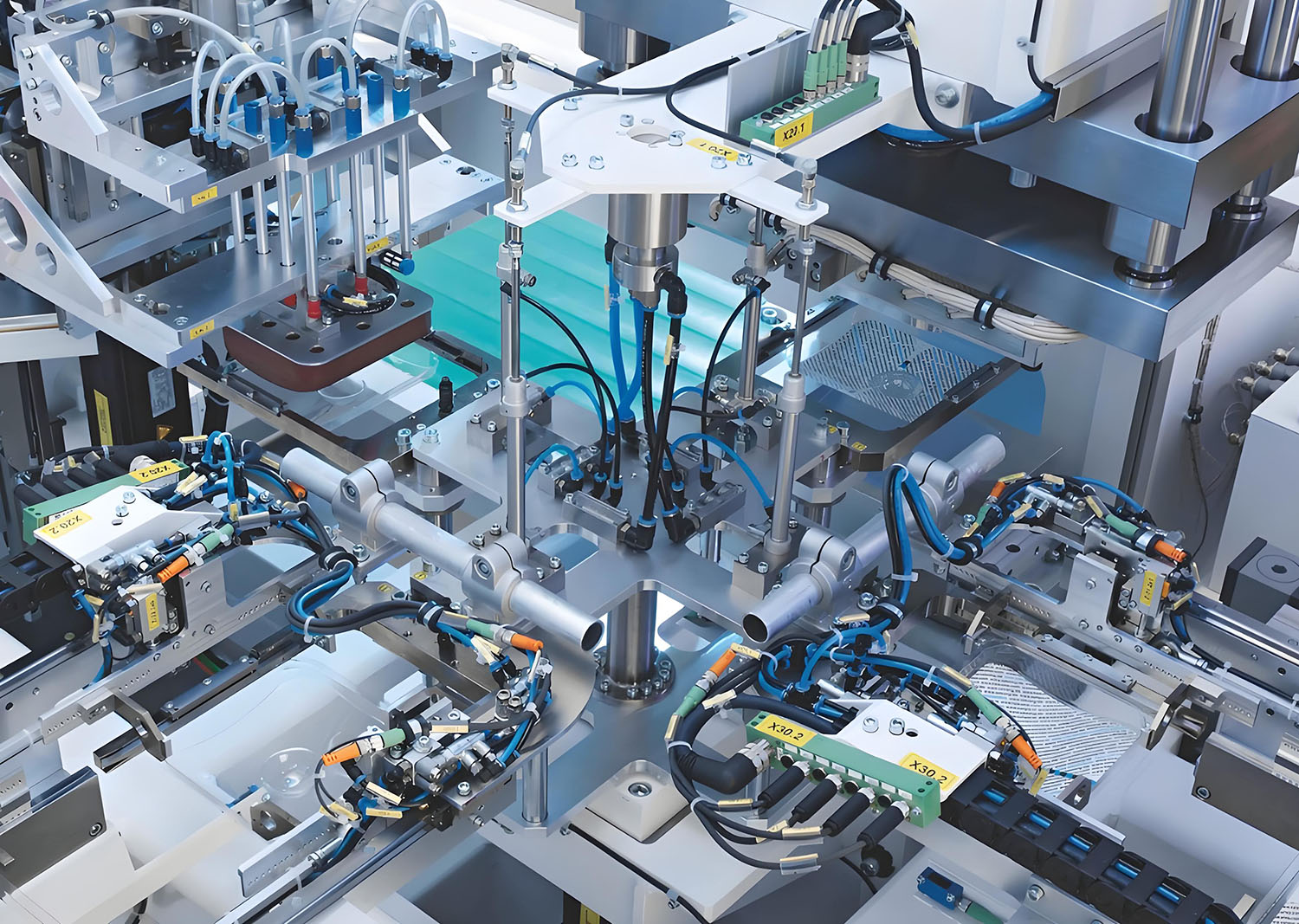

One of the standout features of the Position Hole Punching Machine is its ability to punch multiple holes simultaneously with exceptional accuracy. With speeds of up to 600 pieces per hour, manufacturers can meet the growing demands of the market while maintaining superior quality control. The machine's innovative design allows for multiple layers of inlay sheets to be stacked at once, significantly improving throughput and reducing the time needed for production.

In addition to speed, the Position Hole Punching Machine guarantees precise hole positioning. This is critical in ensuring the correct placement of chips and other components, which directly impacts the functionality of the final product. With high-speed operation and advanced oil cylinder punching technology, the machine offers enhanced production efficiency, particularly when working with varying material thicknesses.

Simplicity Meets Durability

While many industrial machines can be complex and difficult to maintain, the Position Hole Punching Machine is designed with simplicity in mind. Its easy-to-maintain structure ensures that manufacturers can minimize downtime and keep production lines running smoothly. The machine is equipped with high-powered oil cylinders that provide a reliable punching force, allowing it to handle different sheet materials, including PVC and PET, with ease.

The machine’s simple operation makes it easy for operators to use and maintain, reducing the learning curve and the need for extensive training. This translates into a faster return on investment (ROI) for manufacturers, who can immediately start using the machine to boost productivity.

Enhancing Smart Card Manufacturing

The Position Hole Punching Machine is specifically designed for the card manufacturing industry, including contactless cards, RFID cards, and other smart card applications. It is perfect for punching the positioning holes and chip fixing holes required for inlay sheets, ensuring that the cards produced meet the high standards demanded by today’s consumers.

By automating this critical step in the production process, manufacturers can not only increase the speed of their production but also reduce errors associated with manual punching. As a result, they can produce more reliable, high-quality cards, which are essential for applications like digital payments, public transportation, access control, and security systems.

The Future of Card Manufacturing

As the need for faster, more efficient card production grows, the Position Hole Punching Machine is set to play a pivotal role in the future of the smart card industry. Manufacturers are looking for ways to automate processes, improve accuracy, and reduce costs, and this machine meets those demands perfectly.

With its high-speed punching capabilities, precision, and ease of use, the Position Hole Punching Machine is poised to become a go-to solution for manufacturers looking to stay ahead in the competitive and ever-evolving world of smart card production.

As the demand for contactless and RFID cards continues to increase, the Position Hole Punching Machine represents the future of automated manufacturing—offering increased efficiency, reliability, and scalability for businesses worldwide.

Conclusion

The Position Hole Punching Machine is more than just a tool; it’s a game-changer for the card manufacturing industry. With its precision, speed, and efficiency, it enables manufacturers to meet the growing global demand for smart cards, contactless cards, and RFID cards while ensuring high-quality, consistent production. As businesses strive to keep up with technological advancements, investing in innovative machinery like this can provide the competitive edge they need to succeed in an increasingly digital world.

Zowinda’s AI-Powered Envelope

Zowinda’s AI-Powered Envelope

Zowinda Unveils Next-Gen Auto

Zowinda Unveils Next-Gen Auto

Zowinda’s Auto Glue Tape Lamin

Zowinda’s Auto Glue Tape Lamin

Zowinda Envelope Sorting Machi

Zowinda Envelope Sorting Machi

Please contact us with your request

We are ready to answer your questions.