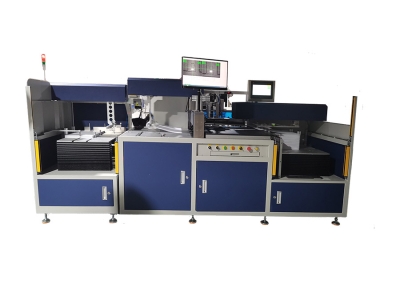

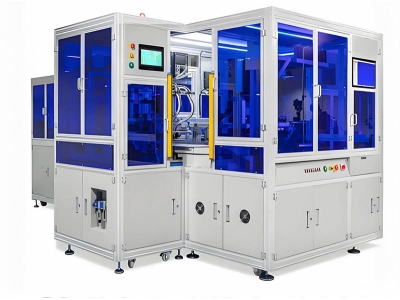

RFID Inlay Sample Bonding Machine

Transform Your RFID Inlay Production with the Latest Bonding Machine

With the rise of RFID (Radio Frequency Identification) technology, the need for precise and efficient RFID inlay sample production has surged. To meet this growing demand, we proudly introduce our RFID Inlay Sample Bonding Machine — an advanced solution designed specifically for laboratory use and the creation of RFID inlay samples. This cutting-edge equipment is tailored to the unique requirements of RFID inlay manufacturing, offering high precision, reliability, and ease of use.

Key Features & Benefits:

1.Wide Application Range:

The RFID Inlay Sample Bonding Machine is an essential tool for testing various RFID inlay components and materials under different conditions, including high and low-temperature environments. It's perfect for research and development labs focused on enhancing RFID technology.

2.Precision Temperature and Humidity Control:

Equipped with advanced temperature control, the machine can achieve a temperature range of -70℃ to +150℃, with minimal fluctuations of ±0.5℃. The humidity range of 20%-98% ensures your samples undergo comprehensive testing under various environmental conditions, adhering to GB/T 5170.2-1996 and GB/T 5170.5-1996 standards.

3.Reliable & Flexible Performance:

The machine features a pressure setting range of 60g to 200g with high accuracy (error margin of 0.05N). It supports UHF RFID chips, and the bonding area accommodates chip sizes ranging from 0.3mm x 0.3mm to 2.5mm x 2.5mm, making it highly versatile for a wide array of RFID inlays.

4.Customizable Chip & Antenna Loading:

The machine is designed to handle different loading methods. The chip tray loading system allows for easy integration, and manual antenna feeding supports flexible material types such as PET, PVC, and paper up to sizes of 120mm x 100mm.

5.Advanced Video Positioning System:

Equipped with 2 visual positioning systems, the RFID Inlay Sample Bonding Machine ensures high accuracy in placement, optimizing the production process.

6.User-Friendly Interface & Control:

The machine features a PLC control system with an intuitive touch screen interface for easy operation. 220VAC power supply ensures compatibility with most laboratory setups.

7.Enhanced Patch Accuracy and Adhesive Compatibility:

With a patch accuracy of 25μm and the ability to work with a variety of anisotropic conductive adhesives, this bonding machine can handle the most demanding applications and deliver superior results.

Applications:

- RFID Inlay Production: Ideal for manufacturing and testing various RFID inlays for use in logistics, retail, and security industries.

- Research & Development: Perfect for R&D labs working on new RFID technologies and testing sample materials under extreme conditions.

Electronics Testing: Suitable for testing RFID components like chips and antennas under temperature and humidity variations.

Technical Specifications:

| Parameter | Details |

|---|---|

| Equipment Size | 640mm (L) x 460mm (W) x 620mm (H) |

| Weight & Power | 35kg, 200W |

| Pressure Setting | 60g to 200g, error margin: 0.05N |

| Temperature Range | 50°C to 250°C (adjustable via touch screen) |

| Chip Size | 0.3mm x 0.3mm to 2.5mm x 2.5mm (UHF & HF) |

| Chip Loading | Tray loading, manual loading (8-inch wafer) |

| Antenna Loading | Manual feeding, compatible with PET, PVC, PAPER |

| Video System | 2 visual positioning systems |

| Control Mode | PLC + Touch screen, 220VAC power supply |

| Patch Accuracy | 25um, compatible with various adhesives |

Why Choose Our RFID Inlay Sample Bonding Machine?

- Enhanced Efficiency: Improve your RFID inlay production with faster, more accurate bonding and testing capabilities.

- Superior Flexibility: Adaptable to a wide variety of materials and chip types.

- Cost-Effective: Lower operational costs with high-efficiency temperature, pressure, and adhesive management.

- Easy Integration: Compatible with existing laboratory equipment and easy to operate with minimal training.