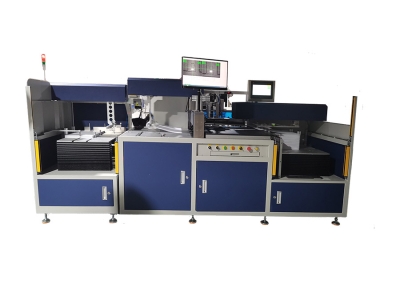

RFID Label Detecting & Encoding Machine – Efficient and Accurate RFID Labeling Solution

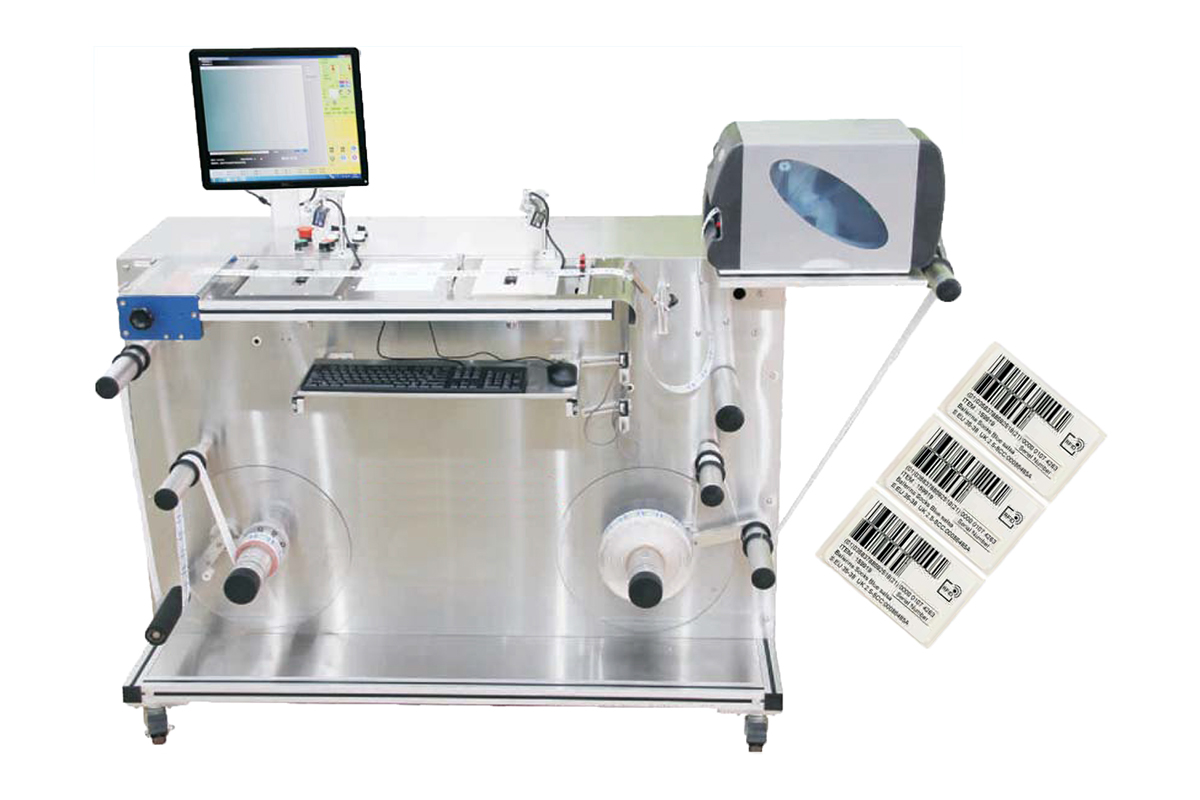

Our RFID Label Detecting & Encoding Machine is a cutting-edge solution designed to streamline the RFID label production process. Ideal for reel-to-reel RFID labels, this machine not only ensures precise detection and encoding but also enhances production efficiency and label quality control. With options for optional features like barcode scanning, inkjet printing, and dual-station encoding, this machine offers an all-in-one solution for RFID label manufacturing.

Key Features & Benefits:

- High-Speed Operation: Equipped with a high-speed servo drive system, it ensures rapid feeding and recycling of RFID labels, optimizing production output.

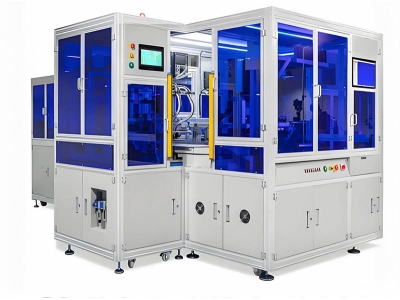

- Dual-Station Encoding: The machine supports optional double-station encoding for enhanced accuracy and seamless operations.

- Advanced Tensioning Roller: Incorporates a tensioning roller structure for precise handling of labels during the detection and encoding process.

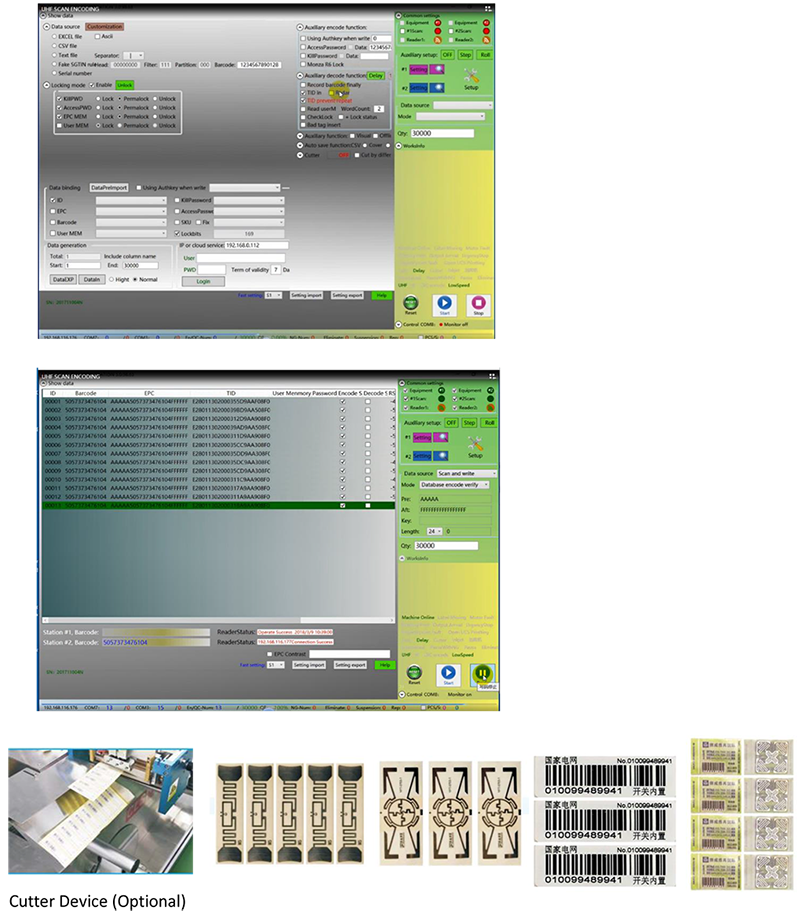

- Versatile Encoding and Printing Options: Optional barcode scanner for EPC data encoding, and optional inkjet printing for additional product marking.

- Comprehensive Control: Comes with a PC-based control system, providing easy operation and the ability to customize settings.

- Flexible Label Specifications: Supports a wide range of label sizes with a width between 20mm and 130mm, and accommodates both UHF and HF RFID reader options.

API Interface Control: Optional API interface for integration with existing systems, offering seamless compatibility.

Applications:

This RFID Label Detecting & Encoding Machine is ideal for various industries including logistics, retail, and manufacturing, where efficient RFID labeling is crucial for inventory management, asset tracking, and quality control. It is designed to meet the needs of companies looking to improve the speed, accuracy, and quality of their RFID label production process.

Application Example:A logistics company uses the RFID Label Detecting & Encoding Machine to automate the labeling process for their shipping inventory. By encoding each package with unique RFID tags, they significantly improve tracking efficiency and reduce human errors in inventory management. The optional barcode scanner ensures the encoding process aligns with specific product details, providing precise control over the labeling and quality assurance.

Technical Specifications:

| Specification | Details |

|---|---|

| Power Consumption | 1000W |

| Power Supply | AC220V/50Hz |

| Control Mode | PC + Servo System |

| Detecting Speed | Max. 600 pcs/min |

| Encoding Speed | Max. 360 pcs/min |

| Laminate Accuracy | ±0.5mm |

| Label Width | 20mm ~ 130mm |

| Label Inner Diameter | Ø76mm |

| Label Outer Diameter | Ø400mm |

| Machine Total Weight | 200Kg |

| Machine Dimensions | 1500mm(L) × 800mm(W) × 1500mm(H) |