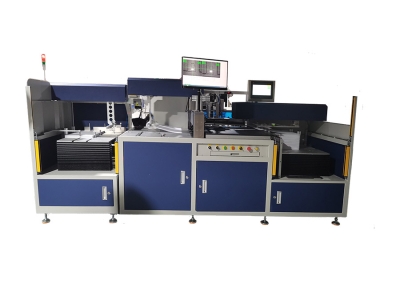

RFID Automatic Flip Chip System – Revolutionizing RFID Inlay Production with High Efficiency and Precision

Zowinda Technology proudly introduces the RFID Automatic Flip Chip System, a state-of-the-art solution designed to meet the growing demands of the RFID industry. With a 99.5% yield rate and a fully integrated system platform, this machine ensures that all processes—from antenna web handling to final testing—are performed seamlessly and efficiently, delivering the highest quality RFID inlays. Ideal for HF and UHF RFID inlays, this system offers complete automation for the production of RFID tags.

Key Features & Benefits

1.High Throughput and Precision:

- Achieves 8500 UPH (Units Per Hour) with bonding accuracy of ±30μm, ensuring high-quality inlays and optimized production speeds.

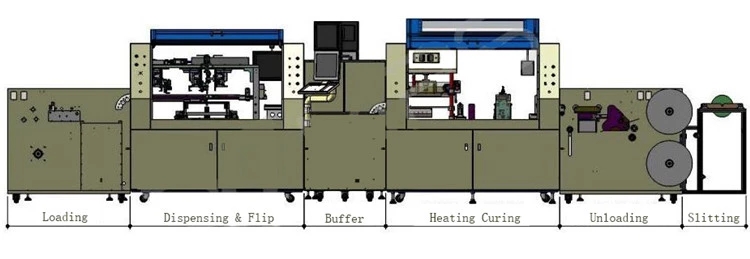

2.All-in-One Solution:

- The system integrates all essential modules including Loading, Dispensing, Flip Chip, Curing, and Testing into a single platform, making it a comprehensive solution for RFID inlay production.

3.Flexible for Different RFID Types:

- Suitable for HF/UHF RFID inlays, allowing businesses to produce a wide range of RFID tags for various applications, from inventory management to logistics.

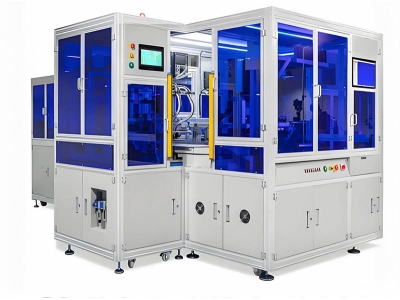

4.Advanced Visual System for Precision Alignment:

- Equipped with a high-speed camera (Basler) for precise chip-to-antenna alignment, ensuring the highest yield and accuracy in the production process.

5.High Efficiency and Automation:

- Servo motors and speed motors (Panasonic, JSCC) power the system, offering robust performance and quick processing for high-volume production lines.

6.Versatile Chip Handling:

- The system supports chips ranging from 0.4mm to 2.0mm in size and accommodates 8" to 12" wafers, providing versatility for different RFID tag designs.

7.Comprehensive Testing and Final Inspection:

- The HF/UHF testing module ensures the RFID inlays meet performance standards before they are shipped, guaranteeing that each inlay functions correctly.

8.Environmentally Controlled Modules:

- Features like heating curing, compressed air, and vacuum pressure ensure optimal production conditions, improving both efficiency and quality.

9.Modular Design for Easy Maintenance and Upgrades:

The system features a modular design, which makes it easy to maintain, repair, and upgrade as needed, ensuring long-term operation with minimal downtime.

Applications:

The RFID Automatic Flip Chip System is ideal for:

- RFID Inlay Production: Creating RFID tags for use in logistics, inventory management, and asset tracking.

- Smart Labels: Used for creating smart packaging solutions in the retail and manufacturing industries.

Electronics Manufacturing: High-precision RFID chips for electronic applications.

Technical Specifications

| Specification | Details |

|---|---|

| Dimensions | 7300mm × 1500mm × 1560mm |

| Power Supply | 10KW AC 220V/50Hz |

| Weight | 4500kg |

| Bonding Speed | 8500 UPH (Related to antenna layout) |

| Bonding Accuracy | ±30μm |

| Wafer Dimensions | 8" or 12" |

| Chip Specification | 0.4 – 2.0mm |

| Compressed Air | 0.45Mpa – 0.6Mpa |

| Vacuum Pressure | -80Kpa – -100Kpa |

| Material Bandwidth | 100mm – 370mm |

| Bound Point Spacing | CD >16mm, MD >30mm |

Why Choose Zowinda's RFID Automatic Flip Chip System?

- Reliability: With years of experience in the RFID technology field, Zowinda’s machine is built for reliability and high-performance, ensuring seamless operation and maximum uptime.

- Cost-Effective: Reduce labor costs and increase productivity with this highly automated system, which pays off in reduced errors and faster production cycles.

- Advanced Technology: Utilizing cutting-edge visual alignment technology and servo-driven motors, our system offers unparalleled accuracy and speed for RFID inlay production.