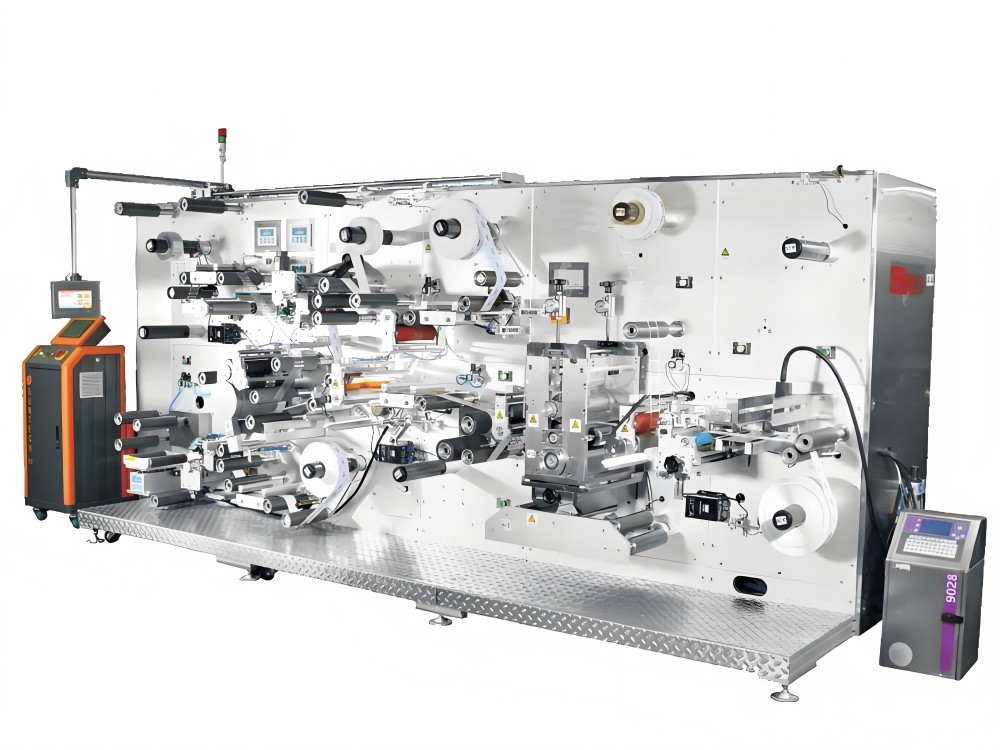

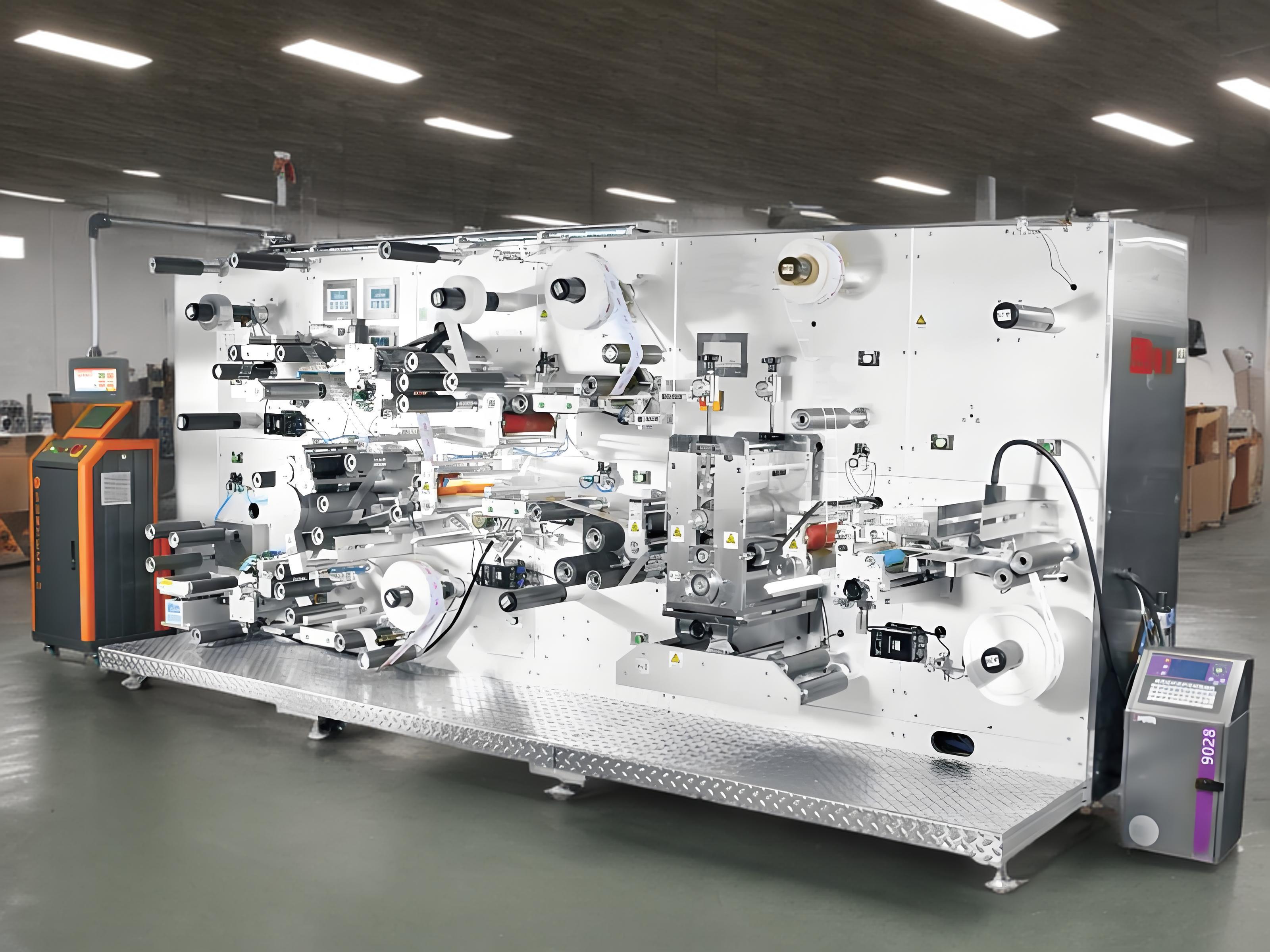

RFID Label Automatic Lamination Machine

Revolutionizing RFID Labeling with the RFID Label Automatic Lamination Machine

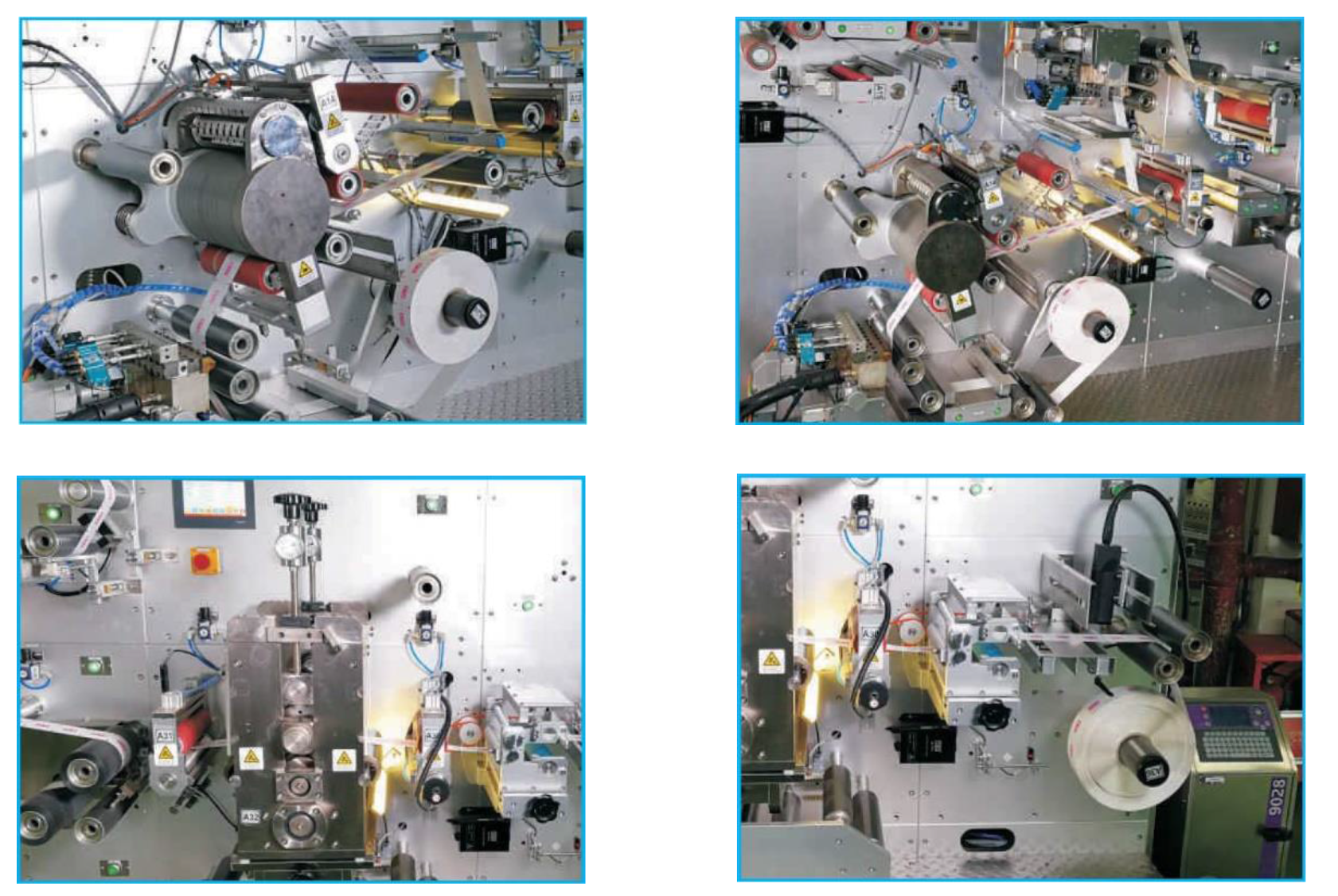

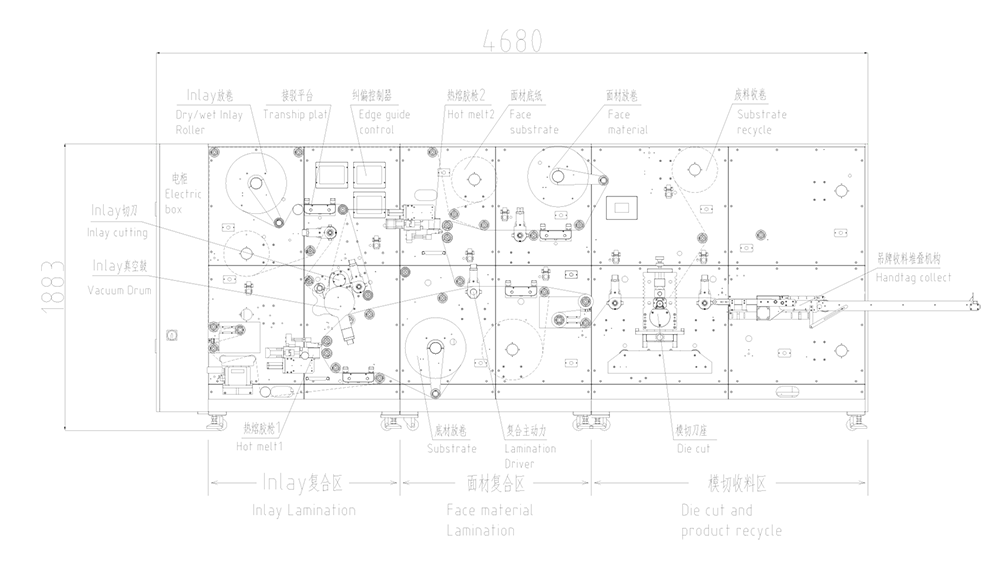

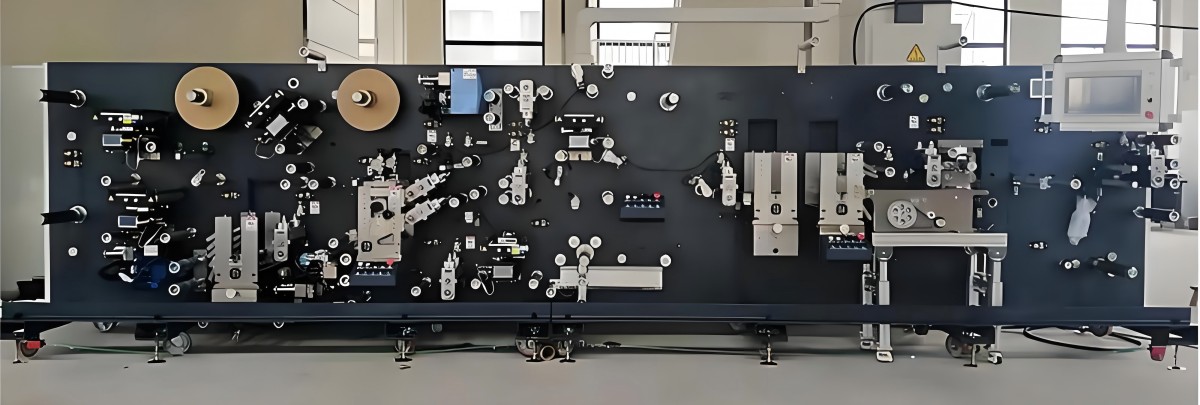

Zowinda Technology Co., Ltd. is excited to introduce the RFID Label Automatic Lamination Machine, a high-performance solution designed to meet the growing demands of modern RFID tag and label production. This advanced machine integrates a variety of technologies to streamline the lamination process for RFID inlays, ensuring superior quality, precision, and high throughput.

The RFID Label Automatic Lamination Machine offers unparalleled flexibility and speed, with a maximum laminating speed of up to 60 meters per minute. Whether you are working with dry inlay or wet inlay, this machine ensures consistent, high-quality laminating for a wide range of RFID labels, including paper, fabric, and silicone-based tags.

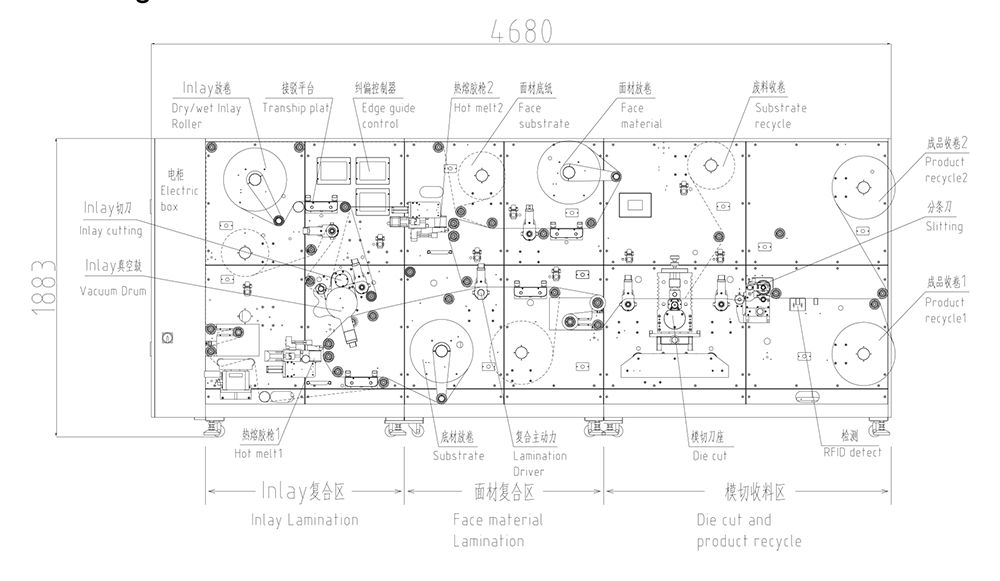

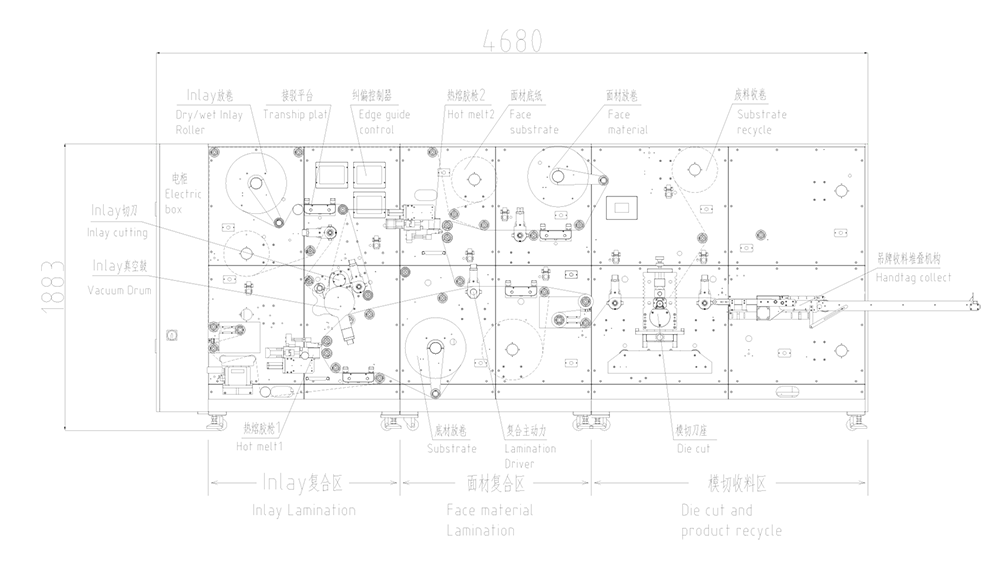

SYSTEM

Key Features

1.Versatile Inlay Lamination

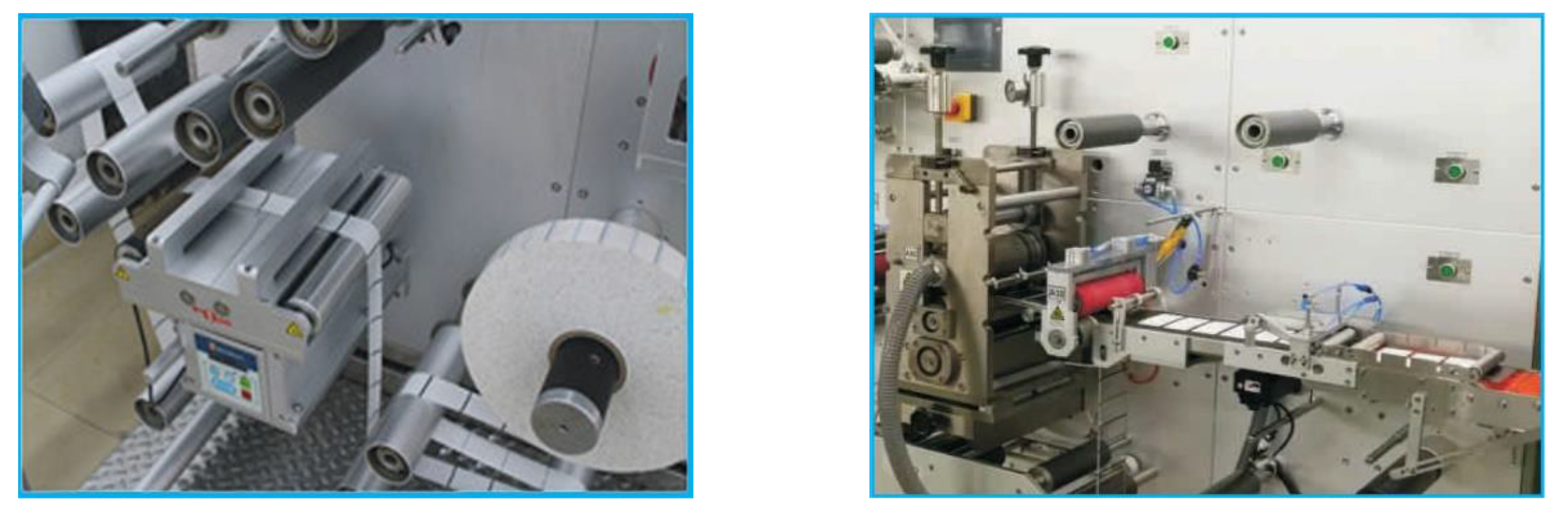

The machine supports both dry inlay and wet inlay lamination with precise inlay positioning cutting and a vacuum drum system. It’s equipped with 3 high-speed deviation rectifying machines, ensuring accurate material alignment throughout the process.

2.Advanced Servo Control

A 13-shaft servo system precisely controls every aspect of the machine, including the main servo feeder institution, hot melt adhesive application, and the roller die-cutting unit. This ensures smooth and stable operation, even at high speeds.

3.High-Speed Die-Cutting

The integrated high-speed magnetic roller die-cutting module guarantees fast and efficient label production, including die-cutting and subsequent card production. The roller die-cut unit operates under servo control for precise, clean cuts.

4.Non-Stop Roll Changing

Equipped with a non-stop lap-changing device, the machine allows operators to change rolls and receive paper without interrupting the lamination process, significantly enhancing efficiency and reducing downtime.

5.Precision Lamination

The machine achieves ±0.5mm lamination accuracy, and with high-precision materials, it can achieve ±0.3mm accuracy. This makes it ideal for producing labels with high-quality printing and tight specifications.

6.Intelligent Speed Control

The machine automatically adjusts speed to maintain perfect alignment throughout the lamination process, ensuring consistent quality and preventing misalignment issues.

7.Comprehensive RFID Label Detection

The built-in UHF/HF RFID detection system ensures that labels meet stringent standards. It includes an inkjet printer for marking NG (No Good) labels, allowing for real-time quality control during production.

Specifications

| Parameter | Specification |

|---|---|

| Production Speed | Max. 60M/Min (depending on label material) |

| Lamination Accuracy | ±0.5mm (±0.3mm with high-precision material printing) |

| Label Maximum Width | 190mm |

| Label Maximum Length | 520mm (die-cut length) |

| Label Thickness | Less than 300g per single layer |

| Label Inner Diameter | φ76mm |

| Label Outer Diameter | Max. φ520mm |

| Power Supply | 3-Phase 380V / 50-60Hz / 18KW |

| Machine Size | 4410mm (L) × 1600mm (W) × 1950mm (H) |

| Machine Weight | 4000Kg |

Main Applications

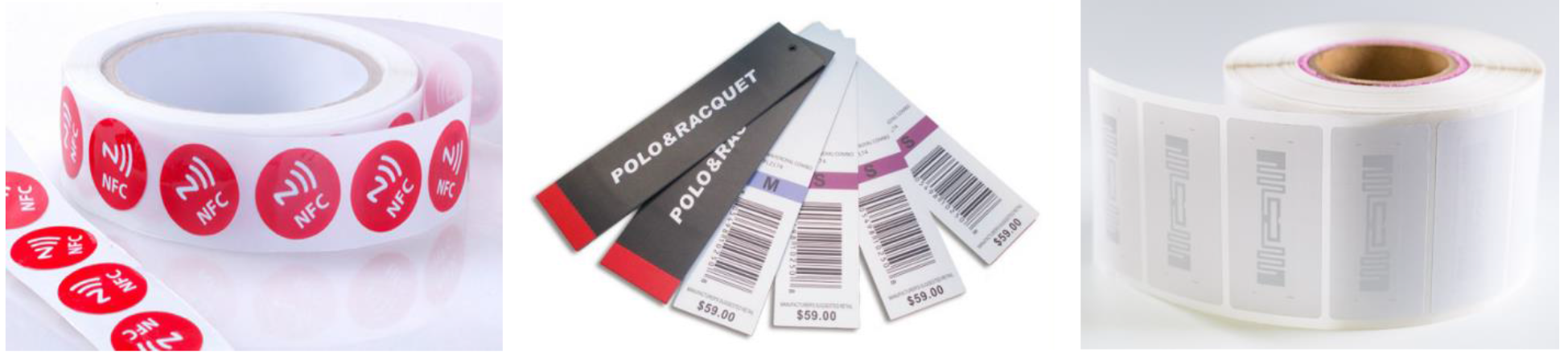

The RFID Label Automatic Lamination Machine is ideal for a variety of RFID labeling applications, including:

- RFID Tag Lamination: Laminating both dry and wet inlay RFID tags for a wide range of uses.

- Hand-Tag RFID: Efficient production of hand-tags, ensuring high-quality lamination.

- Care-Label RFID: Perfect for producing RFID care labels, often used in apparel and textiles.

- Double-Sided Adhesive Labels: Suited for lamination of double-sided adhesive labels with precision.

- Paper-Based RFID Labels: Efficiently laminates paper, fabric, and other materials for a range of RFID applications.

- Silicone Oil-Based Laminating: Able to handle silicone oil body paper for more complex RFID label materials.

Why Choose Zowinda’s RFID Label Automatic Lamination Machine?

The RFID Label Automatic Lamination Machine from Zowinda Technology Co., Ltd. is designed to meet the needs of modern RFID production environments. It not only ensures high-speed lamination and precise cutting but also enhances operational efficiency with features like automatic roll change and real-time feedback systems. By streamlining the RFID label production process, it helps manufacturers achieve higher throughput, better quality control, and reduced operational costs.

About Zowinda Technology Co., Ltd.

Zowinda Technology Co., Ltd. is a leading provider of advanced manufacturing solutions for the RFID industry. Specializing in high-performance machinery for RFID inlay, tag production, and card manufacturing, Zowinda delivers innovative solutions designed to increase production efficiency and ensure consistent, high-quality output.

For more information on the RFID Label Automatic Lamination Machine or to discuss your specific RFID production needs, visit our website or contact us directly.