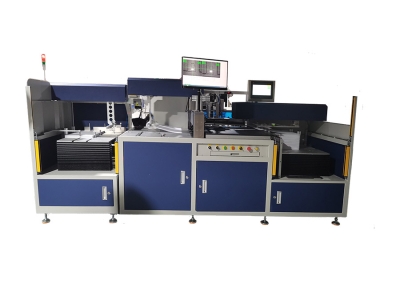

Auto Glue Tape Lamination Machine,Enhancing Precision and Efficiency in Smart Card Production

In today’s fast-evolving contactless card industry, manufacturers require high-speed, precision-driven, and automated solutions to meet growing market demands. The Auto Glue Tape Lamination Machine is the ultimate solution designed to streamline the lamination of glue tape for various IC modules. This cutting-edge machine enhances production efficiency, ensuring reliable and high-quality output for applications such as smart cards, RFID cards, and contactless payment solutions.

Key Features & Benefits

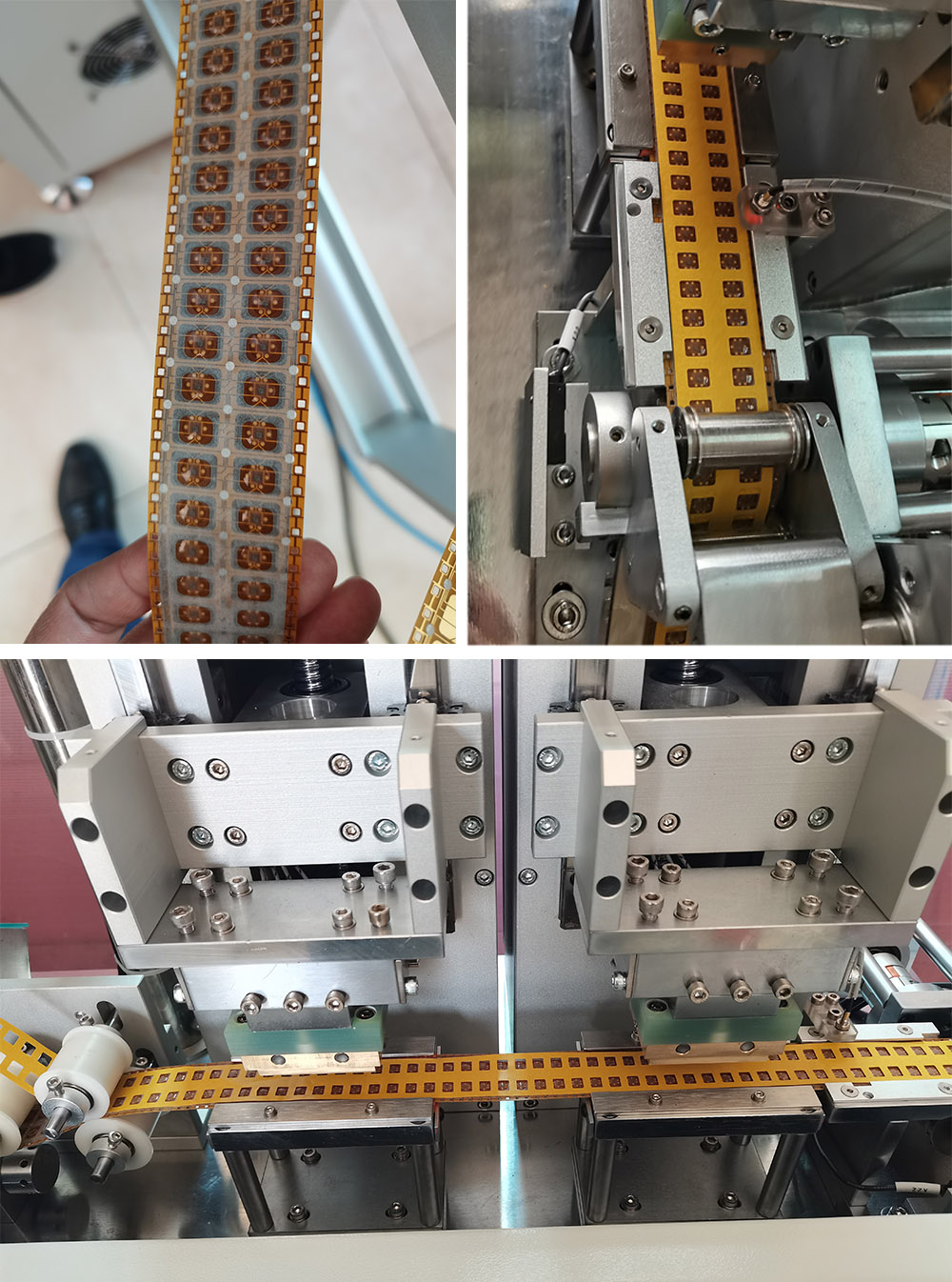

1. Automatic Punching & Cutting for Unmatched Precision

The machine integrates an automated punching and cutting system that precisely applies hot melt adhesive tape onto IC modules. This feature enhances production speed while maintaining consistent and high-precision glue application, ensuring quality across different chip models.

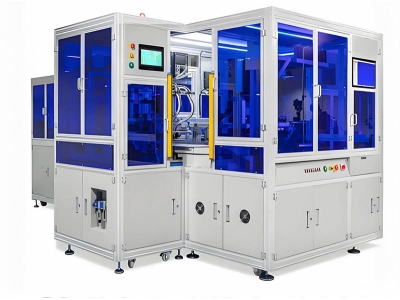

2. Smart PLC Control with User-Friendly Interface

Equipped with a PLC-based automatic control system, the machine ensures smooth and stable operation. The large touchscreen interface allows operators to easily adjust parameters, making the production process highly intuitive and flexible.

3. Servo-Controlled Module Stepping for Maximum Accuracy

A servo motor system regulates the module stepping mechanism, allowing precise adjustments to pulling distances. The advanced photoelectric sensor monitoring system provides double protection for modules, ensuring error-free production with high reliability.

4. Versatile & Adaptable for Various Production Needs

This machine supports multiple functionalities, including:

IC module stripe lamination

Hot melt glue conveyance

Rush glue application

Hot welding glue lamination

Finished module stripe collection

Its adaptable design allows seamless switching between 6-pin and 8-pin IC module glue tape lamination without requiring mold changes, significantly reducing downtime and maximizing efficiency.

Technical Specifications

| Specification | Details |

|---|---|

| Machine Dimensions | L1700 × W520 × H1650 mm |

| Weight | Approximately 300 kg |

| Power Supply | AC 220V 50/60Hz |

| Power Rating | About 1.5 KW |

| Control Mode | PLC + Touchscreen |

| Production Speed | 11,000 – 15,000 chips/hour |

Why Choose the Auto Glue Tape Lamination Machine?

✅ High Production Efficiency

Capable of laminating 11,000 – 15,000 chips per hour, significantly increasing production capacity.

✅ Easy to Operate & Maintain

Features a large touchscreen control panel and an intuitive interface for seamless operation.

PLC-controlled automation ensures stability and reliability, reducing errors and maintenance costs.

✅ Flexible Production Capabilities

Allows effortless switching between 6-pin and 8-pin IC module configurations, making it adaptable to various smart card production needs.

✅ Superior Reliability & Accuracy

Servo-controlled stepping system guarantees precise movement and alignment.

Photoelectric sensors enhance safety and reduce production errors.

Industry Applications

The Auto Glue Tape Lamination Machine is essential for manufacturers producing:

Contactless Payment Cards (Credit, Debit, and Gift Cards)

RFID Cards

Smart Cards (Identification, Access Control, Security Badges)

Security & Banking Cards

Whether for financial transactions, identification systems, or access control applications, this machine ensures high-performance, durability, and consistency in chip lamination.