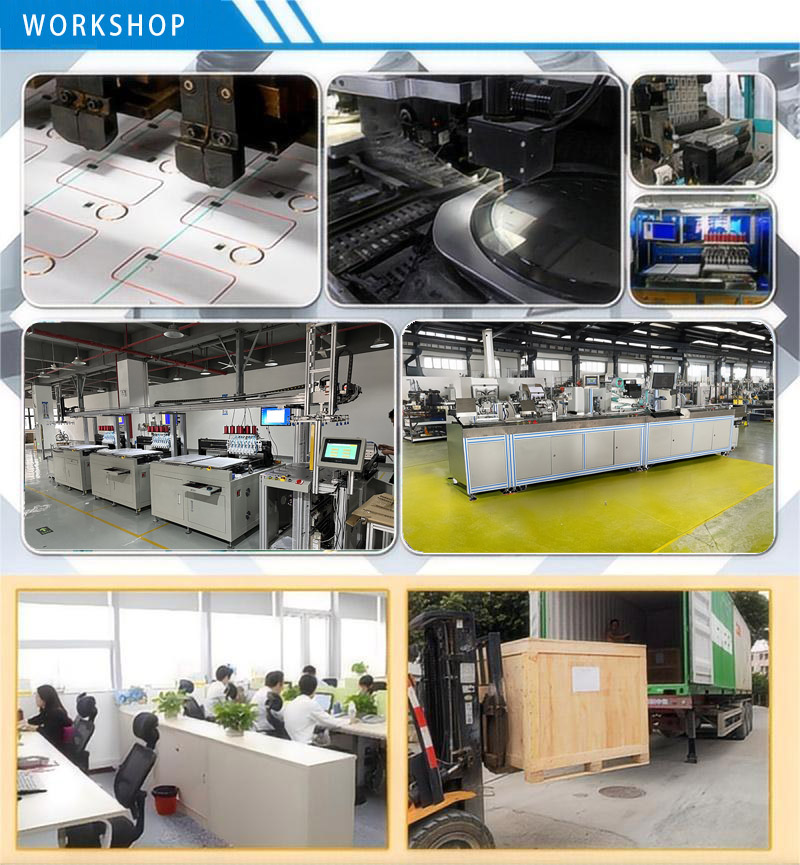

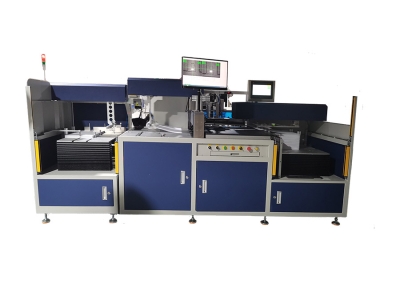

Auto Hole Punching Machine – Precision & Efficiency for Your Production Line

Unlock the Full Potential of Your Production Line with the Auto Hole Punching Machine

The Auto Hole Punching Machine is a state-of-the-art solution engineered to meet the demands of precision and efficiency in chip hole punching on sheets. Whether you're working with materials such as PVC, PET, or other compatible materials, this machine offers a seamless, automated process that guarantees consistent, high-quality results for your manufacturing needs.

Why Choose the Auto Hole Punching Machine?

In today’s fast-paced production environment, precision and speed are paramount. The Auto Hole Punching Machine stands out for its ability to deliver both, improving operational efficiency while ensuring optimal quality. From small enterprises to large-scale manufacturers, this machine can elevate your production capabilities and meet the high standards required in electronics, packaging, and other sectors.

Key Features & Advantages

1. Precision Punching Technology

This machine is purpose-built for chip hole punching, delivering clean, precise cuts in a wide variety of materials. This ensures that each component fits perfectly and functions optimally, increasing the overall quality and performance of your products.

2. Intuitive Touch Screen Control

With a user-friendly touch screen interface, the Auto Hole Punching Machine simplifies operation. Operators can easily navigate through settings, adjust parameters, and monitor the machine’s performance in real time, ensuring a smooth and fast learning process.

3. Versatile Punching Sizes

Equipped with double-cylinder punching pins, this machine offers exceptional flexibility in terms of punching sizes. With just a touch of a button, operators can switch between different punching sizes, enabling quick adaptation to varying production needs.

4. High-Precision Servo Motor Drive

The machine uses an imported ball-screw system, driven by a high-precision servo motor. This guarantees accurate positioning and feeding, making the Auto Hole Punching Machine ideal for applications where precise alignment is crucial.

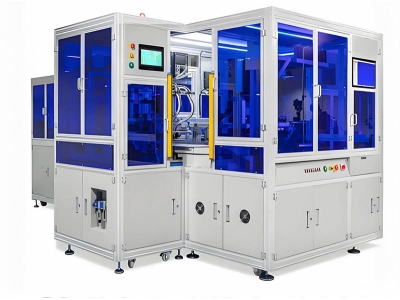

5. Flexible Feeding and Punching Configurations

Choose from a variety of setups, including three-mold, four-mold, and five-mold configurations. This flexibility allows you to optimize your production line for different projects, balancing speed and efficiency to meet specific requirements.

6. Reliable INLAY Sheet Handling

The servo-driven system ensures precise feeding, collecting, and punching of INLAY sheets, minimizing the risk of errors and streamlining the production process. This results in a more efficient operation, reducing material wastage and downtime.

7. Customizable Speed and Positioning

Adjust the feeding speed and chip hole positions directly via the touch screen. This full customization helps to improve operational efficiency and allows you to quickly shift production focus based on changing demands.

8. Dual Punching Capability

The machine supports dual punching sizes for the same chip type, providing versatility to handle various components without sacrificing performance. This dual-functionality ensures greater adaptability to different production requirements.

9. Robust Construction for Durability

Built with high-quality materials, the Auto Hole Punching Machine is designed for durability and long-term performance. Its sturdy construction ensures that it can withstand the rigors of high-volume production in demanding environments.

10. Easy Maintenance

Routine checks and repairs are simplified due to the easy-access components, which minimize downtime and keep your production line operating at peak efficiency.

Technical Specifications

| Feature | Specification |

|---|---|

| Power Source | AC 220V, 50/60 Hz, 20A |

| Power Consumption | 0.6 KW |

| Compressed Air Requirement | 6 kg/cm² |

| Air Consumption | 20 L/min |

| Weight | 300 kg |

| Speed | Up to 450 sheets/hour |

| Dimensions | L1650 mm × W700 mm × H1500 mm |

| Control Method | Servo positioning + PLC |

| Operator Requirement | 1 Person |

| Material Specifications | Suitable for 0.2–0.4 mm PVC, PET, etc. |

Conclusion: Transform Your Production Line with Precision and Efficiency

The Auto Hole Punching Machine is more than just an industrial tool—it’s a game-changer for any production line looking to boost efficiency without sacrificing precision. With its advanced technology, user-friendly interface, and reliable performance, this machine is the ideal choice for manufacturers in industries ranging from electronics to packaging.

By embracing automation with the Auto Hole Punching Machine, you ensure that your production line operates faster, more accurately, and with a higher degree of consistency.

Elevate your manufacturing capabilities and ensure top-tier quality—contact us today to learn how this innovative solution can transform your production process.