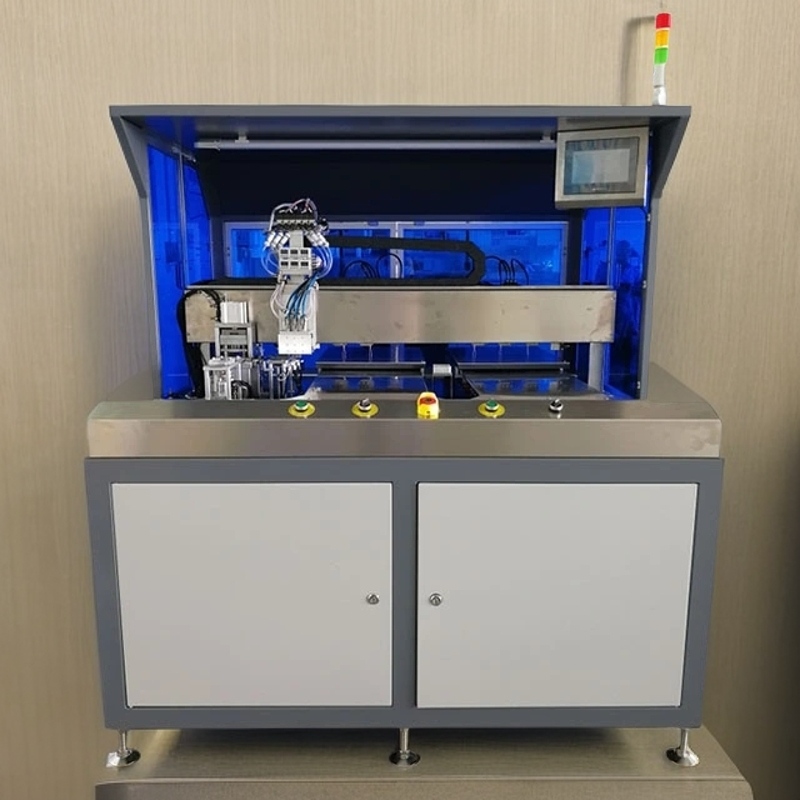

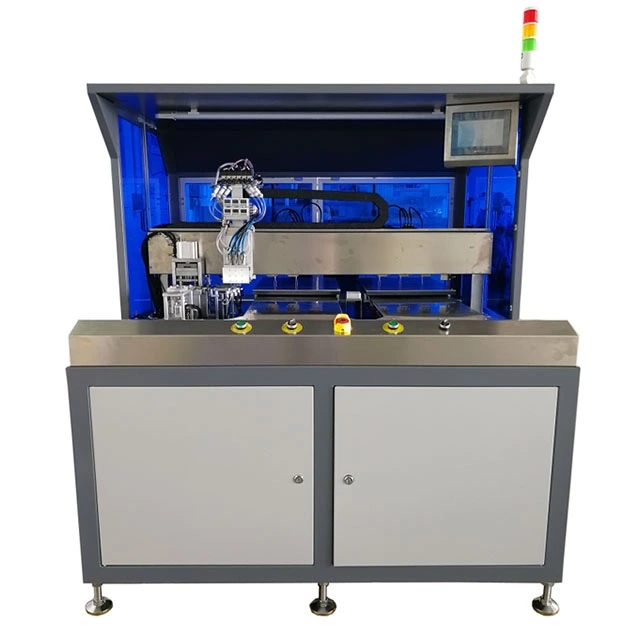

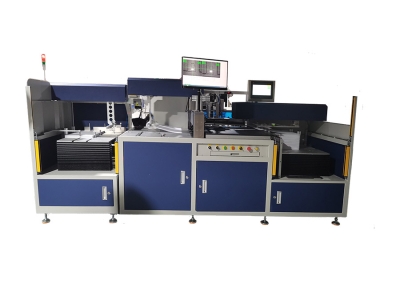

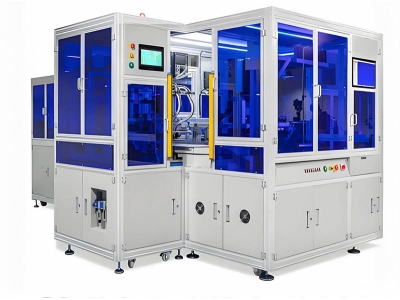

Auto COB Pick and Placer Machine Chip-On-Board placement machine

Short Description:

The Auto COB Pick and Placer Machine is an advanced automated solution designed for precision Chip-On-Board (COB) placement. Offering high-speed assembly with up to 4000 PCS/hour, the APP-3000 ensures exceptional accuracy (0.05mm) with integrated glue dispensing. It features versatile layout options, a user-friendly interface, and intelligent monitoring for reliable, efficient electronic manufacturing. Upgrade your production line with this powerful machine to enhance productivity and reduce errors in your electronics assembly process.

Product Details

Product Tags

Auto COB Pick and Placer Machine: Revolutionizing Your Electronics Assembly Process

Unlock the potential of your production line with the Auto COB Pick and Placer Machine, a state-of-the-art solution designed to elevate the Chip-On-Board (COB) placement process. Tailored for high-efficiency and precision, the APP-3000 automates the COB handling process, ensuring a seamless manufacturing experience that meets the demands of modern electronics assembly.

In today’s competitive and fast-paced electronics market, precision and speed are paramount. The APP-3000 not only meets these demands but exceeds them, offering a reliable solution to streamline your production and maximize throughput.

Key Features and Benefits:

Fully Automated COB Handling

Transform your production line with the APP-3000’s fully automated COB handling system. Simply load the roll tape, and the machine efficiently punches out chips from the tape, reducing manual labor and the potential for errors. Enjoy hassle-free operation with a consistent, automated process.

Enhanced Productivity

With the ability to pick 6 chips simultaneously, the APP-3000 ensures exceptional productivity. Capable of placing up to 4000 PCS/hour, this machine is perfect for high-demand production environments. It helps you keep pace with the increasing need for faster production times without sacrificing quality.

Versatile Layout Options

The APP-3000 is designed to meet your specific production needs with flexible layout options. It supports 3x7 and 3x8 sheet layouts and includes dual A and B platforms. The flexible 3-axis work mode (AY axis, BY axis, and X axis) allows for easy adjustment of COB placing parameters to accommodate various project requirements.

Simultaneous Glue Dispensing

Maximize your production line's efficiency with 6 integrated glue dispensing units. The APP-3000’s glue dispensing and pick-and-place functions operate simultaneously, minimizing downtime and accelerating the assembly process, ensuring maximum productivity.

High Precision and Accuracy

Designed with an advanced X-Y double axis system powered by a servo motor, the APP-3000 offers placing accuracy up to ±0.05 mm. This extreme precision is critical for maintaining the integrity of your electronic components and ensuring the quality of every assembly.

Intelligent Monitoring System

Equipped with an intelligent monitoring system, the APP-3000 continuously checks operational status through an array of sensors. In case of any irregularities, the machine automatically halts and triggers an alarm, providing peace of mind during operation and ensuring reliability throughout your production process.

User-Friendly Interface

The APP-3000 features an intuitive interface that simplifies operation. Operators can easily adjust settings, monitor performance, and troubleshoot with minimal training. This user-friendly design ensures that your team can focus on productivity, minimizing operational disruptions.

Compact and Efficient Design

The APP-3000 is designed to fit seamlessly into your production environment. Its compact footprint provides maximum functionality without taking up unnecessary space, making it an ideal choice for any production floor.

Durable Construction for Long-Term Use

Built with high-quality materials, the APP-3000 is designed for longevity. Its robust construction ensures that it can withstand the demands of a high-speed production environment, providing a reliable solution for years to come.

Technical Specifications:

| Specification | Details |

|---|---|

| Power Source | AC 220V/50 Hz |

| Power Consumption | Approximately 3.0 KW |

| Air Pressure | 6 kg/cm² (dry, no water) |

| Air Consumption | Approximately 30 L/min |

| Dimensions | L1530 × W1460 × H1730 mm |

| Weight | Approximately 950 kg |

| Capacity | Up to 4000 PCS/hour |

| Control Method | PLC Program + Servo System |

| Operator Requirement | 1 Person |

| Material Compatibility | Chips in tape format; compatible with PVC, ABS, and PETG sheets featuring chip holes |

| Position Accuracy | ±0.05 mm |

Conclusion:

The Auto COB Pick and Placer Machine (APP-3000) is more than just an equipment upgrade; it’s a transformative tool for your production line. With its unparalleled speed, precision, and cutting-edge features, the APP-3000 will empower your business to stay ahead in a competitive market. Improve your electronic assembly process, enhance productivity, and embrace the future of manufacturing with the APP-3000—where speed, accuracy, and innovation meet.

Upgrade your production capabilities today with the Auto COB Pick and Placer Machine and see how it can take your operations to the next level. Contact us for more information and discover how we can help optimize your manufacturing process!

A: We are factory.

A: Yes, we are the source manufacturer of research and development and production, with our own research and development team that can customize products according to customer requirements.

A: Please provide detailed customization requirements, and we will provide a quotation according to your customization requirements.

A:Yes, we can. Your design is accepted , your own logo can be used on the machine.

A:We provide remote video guidance or on-site after-sales service, and we have a professional after-sales service team.

A:We accept L/C ,T/T Bank transfer, Paypal ,Western union as payment.

A: We do not require MOQ, small order is also welcome.

A: Please provide your detailed functional and performance requirements for the product, and our sales team will provide a quotation for your product

9.Q:What's your delivery time?

A:As the equipment is a customized service, we will make a shipment cycle prediction based on the difficulty level of your customized equipment research and production, and provide you with a satisfactory shipment cycle.

10.How about the warranty?

A:We provide a one-year warranty service for the machine, and we will also provide long-term paid after-sales service if it exceeds one year.

11.Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Leave Your Message

Related PRODUCTS

-

Auto Sheet Trimming Machine - High-Preci

-

Auto Contactless Card Inlay Sheet Manufa

-

Automatic Milling & Implanting Machi

-

Automatic IC Module Implanting Machine

-

Auto Envelope Sealing and Labeling Machi

-

Automatic Module Testing Machine

-

Automatic 3D Curved Antenna Embedding Ma

-

Automatic Frequency Test Machine

-

Auto Wire Embedding Machine (2-in-1 Syst

-

Integrated Inlay Manufacturing System_Ch