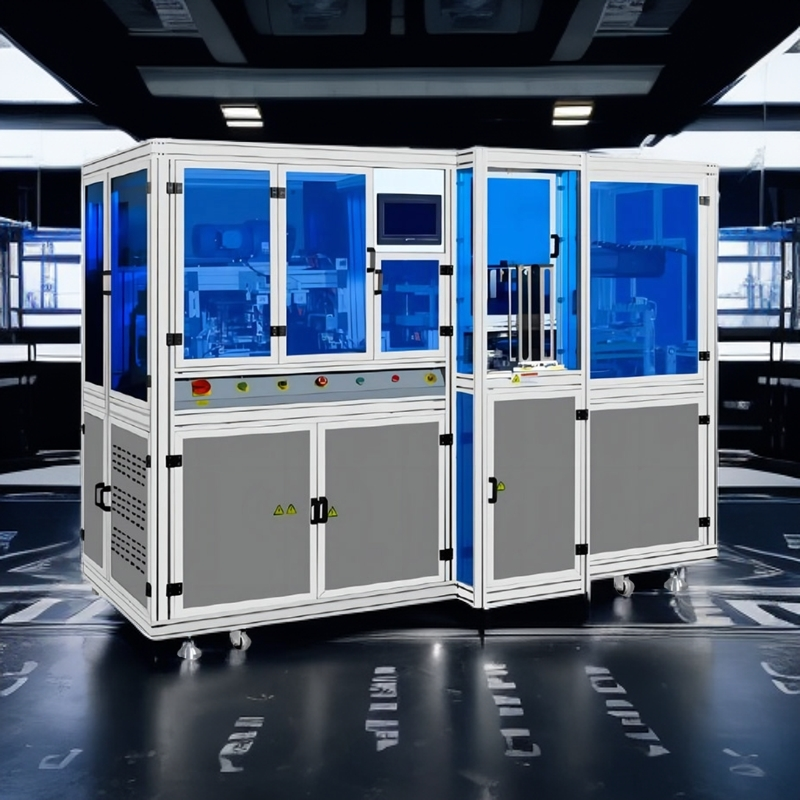

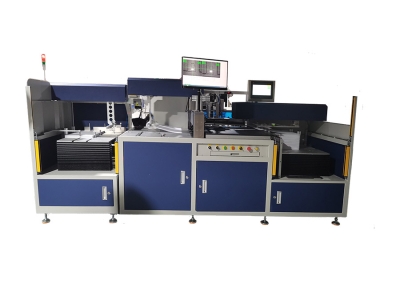

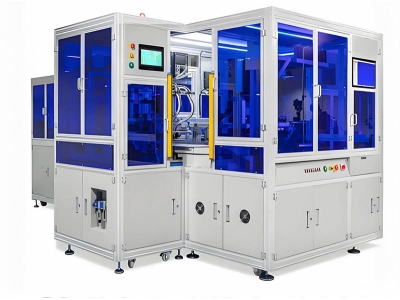

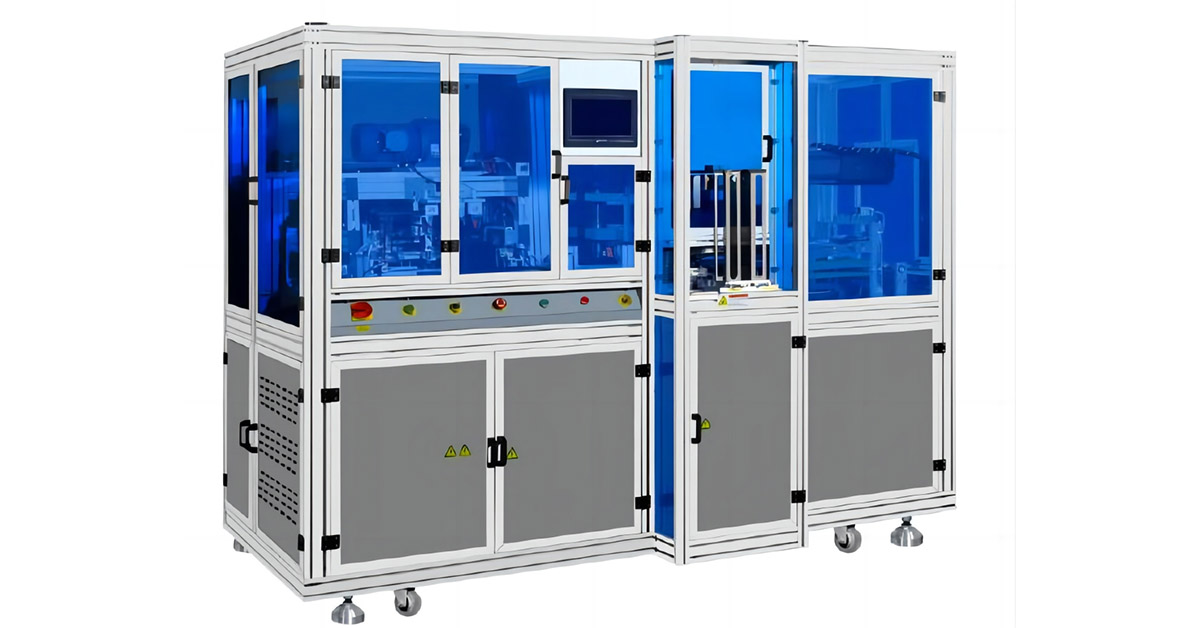

Automatic Sheet Collating and Overlay Laminating Machine

Automatic Sheet Collating and Overlay Laminating Machine

Optimize your card production line with the Automatic Sheet Collating and Overlay Laminating Machine. Designed for high-precision sheet collating and overlay laminating, this advanced machine integrates a series of automated processes, including auto sheet loading, material correction, CCD vision detection, sheet collating, overlay lamination, ultrasonic welding, and cutting. Ideal for customers requiring top-tier precision in card production, this equipment enhances both productivity and quality, making it an essential addition to modern manufacturing workflows.

Key Features and Benefits:

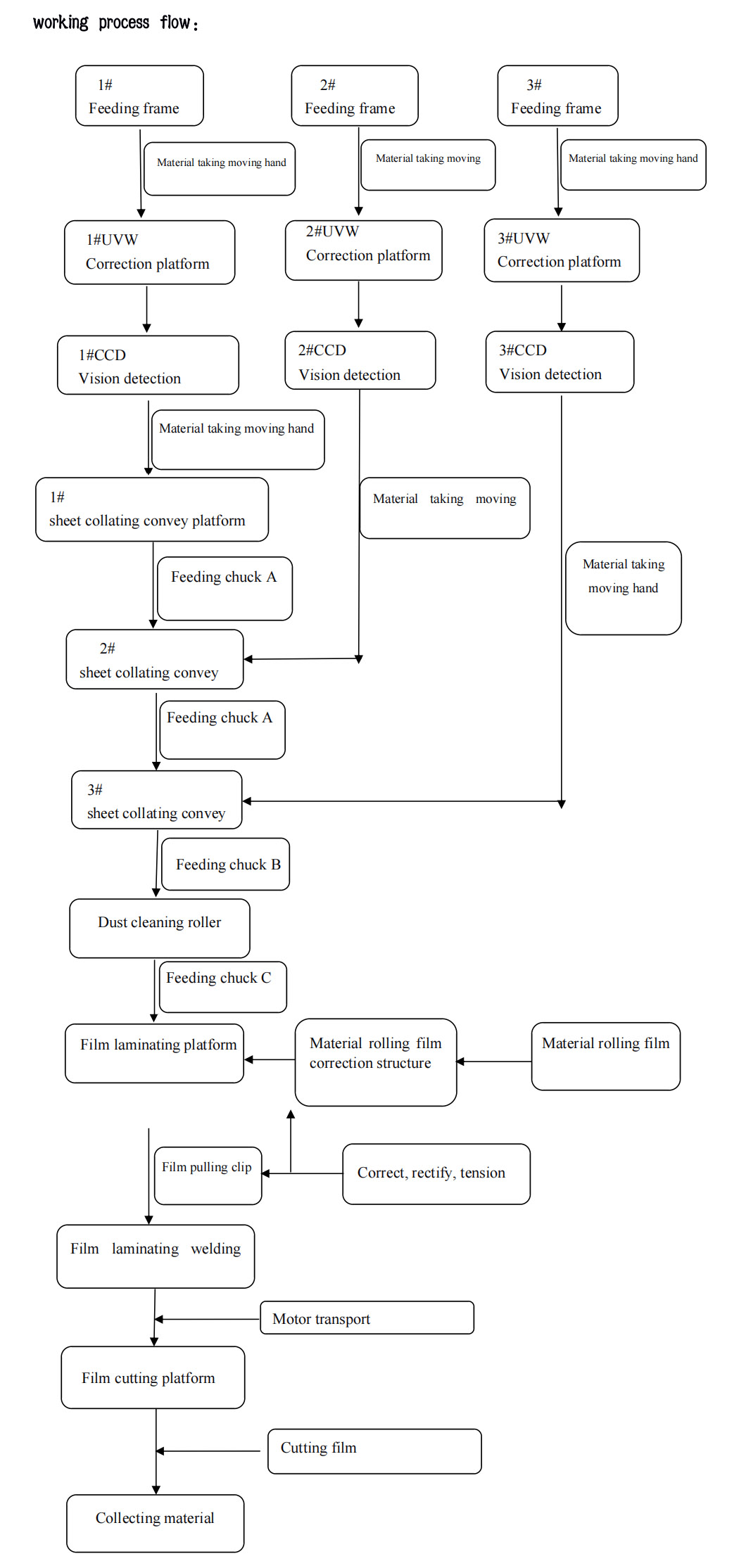

1.Automatic PVC Sheet Loading

- The machine features three automatic sheet collating feeding frames, each with a gear motor-controlled lifting platform for efficient material loading and sheet separation. The feeding system uses a cylinder fixed structure for precise sheet positioning, ensuring smooth and consistent material handling.

2.High-Precision UVW Correction Platform

- Each feeding frame is paired with a UVW correction platform, equipped with a cross roller and step motor for precise correction in the X and Y directions. This system guarantees that each PVC sheet aligns perfectly during the collating process, ensuring accuracy in the overlay laminating stage.

3.CCD Vision and Color Code Magic Eye Counterpoint

- The machine integrates CCD vision detection that automatically detects the position of the material’s color code. By comparing it to the preset deviation values, the system adjusts the position in real time, providing ultra-accurate alignment and material correction.

4.Material Taking Moving Arm

- The high-precision module, combined with a lifting air cylinder and vacuum suction board, transports materials from the feeding frame to the correction platform. The vacuum suction board then moves the corrected material to the collating platform, ensuring seamless handling and minimal errors.

5.Sheet Collating & Conveying Platform

- The servo feeding clamps (A & B) are designed for efficient sheet movement and alignment. Clamp A conveys material between collating positions, while Clamp B moves the aligned sheets to the dust removal system. Clamp C then transfers the sheets to the overlay laminating platform.

6.Ultrasonic Spot Welding for Sheet Collating

- Beneath the #3 collating platform, an ultrasonic head performs spot welding once the third sheet is collated, ensuring that the sheets remain perfectly aligned for the following processes.

7.Dust Cleaning and Film Laminating

- Prior to collating and laminating, the machine employs a sticky dust roller and tear-off sticky paper to clean the PVC sheets, ensuring optimal film adhesion. When the sticky paper is used up, operators can easily replace it with a new roll.

8.Material Roll Film Correction Structure

- The material roll film correction system ensures that the overlay film is neatly aligned and positioned for hot welding and lamination, ensuring precise and consistent film application.

9.Film Laminating Platform

- Equipped with two ultrasonic heads, the laminating platform performs spot welding and hot melting of the overlay film. The overlay is clamped and moved to the ultrasonic weld heads for secure bonding, ensuring high-quality lamination.

10.Film Cutting Platform

- A servo motor drives the finished material to the cutting platform. A positioning electric eye ensures perfect alignment with the cutting blade, which is then controlled by the motor to accurately cut the overlay film.

Main Technical Parameters:

| Parameter | Specification |

|---|---|

| Voltage | AC380V 50/60Hz |

| Air Source | 6Kg/cm² |

| Control Method | PLC + Servo System |

| Positioning | CCD Visual System |

| Output | 700-900 /hour |

| Power | 8KW |

| Collating Accuracy | ±0.1mm |

| Format | 3X8, 4X8 |

| Machine Size | L3700 × W3200 × H1900 mm |

| Weight | About 6000 kg |

Conclusion

The Automatic Sheet Collating and Overlay Laminating Machine is a cutting-edge solution for businesses that demand high precision and efficiency in their card production processes. With advanced features like CCD vision detection, ultrasonic welding, and servo-driven control, this machine ensures optimal alignment, quality, and speed. Whether you're working with PVC or other compatible materials, this machine is designed to meet the demanding needs of modern manufacturing, reducing manual labor and enhancing production efficiency.

Contact us today to learn more about how the Automatic Sheet Collating and Overlay Laminating Machine can elevate your production line and help you stay ahead in the competitive market.