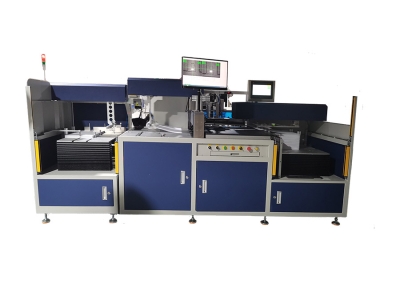

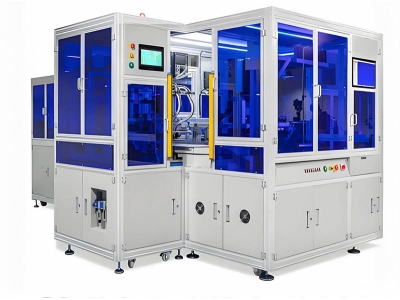

Auto Antenna Embedding Machine – Advanced Solution for Efficient Contactless Card Manufacturing

Short Description:

The Auto Antenna Embedding Machine is a high-precision automated solution for embedding antennas into inlay sheets, ideal for contactless cards, RFID cards, and smart card manufacturing. Featuring ultrasonic embedding technology, dual vacuum platens, and PC control, it ensures high-speed, efficient, and accurate antenna placement. Perfect for high-volume production, this machine provides customization options and flexibility for various card layouts. Increase productivity, reduce labor costs, and enhance the reliability of your production line with this cutting-edge antenna embedding machine.

Product Details

Product Tags

Auto Antenna Embedding Machine – Advanced Solution for Efficient Contactless Card Manufacturing

Overview

The Auto Antenna Embedding Machine is a state-of-the-art solution designed to automate the process of embedding antennas onto inlay sheets, which are essential components in the production of contactless cards, RFID cards, and smart cards. This advanced machine is equipped with cutting-edge features such as PC control, ultrasonic embedding technology, and dual vacuum platens. With high precision, efficiency, and flexibility, this machine is the ideal choice for manufacturers looking to scale production without compromising quality.

The machine is engineered to handle high-volume production runs and is equipped with a wide LCD touch screen for ease of operation and a biaxial servo system for precision. It allows manufacturers to embed antennas of various shapes and sizes onto inlay sheets efficiently and consistently.

Key Features

1.High-Precision Antenna Embedding

The machine’s vacuum aspirating platform ensures the precise positioning of materials, preventing any shifting during the embedding process. This guarantees smooth and accurate antenna attachment.

2.Advanced Ultrasonic Embedding Technology

The ultrasonic embedding system ensures the consistent attachment of antennas, even for intricate or delicate designs. This technology provides a strong, reliable bond between the antenna and the inlay sheet.

3.Flexible Sheet Layout Compatibility

Designed to support various inlay sheet layouts, such as 3×8, 4×8, and 5×5, the machine can be easily adapted to suit different production needs without requiring additional tooling.

4.PC Control with Professional Drawing Software

The machine’s PC control system, coupled with professional drawing software, allows operators to design and program the antenna embedding path. This flexibility makes it simple to adjust for different antenna geometries, improving overall production efficiency.

5.Dual Vacuum Working Platens for Continuous Production

Equipped with two vacuum platens, the machine ensures continuous operation without downtime, allowing for rapid material changes during production.

5.High-Speed Embedding

Capable of embedding up to 400 antennas per hour, this machine helps manufacturers meet the growing demand for RFID and contactless cards.

7.Customizable and Intuitive Operation

The machine can be easily tailored to accommodate various antenna shapes and sizes. Its intuitive interface makes it simple to operate and adjust, whether for small or large batch production.

Machine Specifications

| Parameter | Details |

|---|---|

| Power Supply | AC 220V, 50/60Hz |

| Power Consumption | ~3KW |

| Compressed Air | 6 kg/cm² |

| Machine Weight | ~800 kg |

| Speed | 400 antennas per hour |

| Dimensions | L1780 mm × W11400 mm × H1600 mm |

| Control Method | Servo positioning + PLC control |

| Operator | 1 person |

| Material Specifications | 0.2~0.4mm (PVC, ABS, PET, PETG) |

Applications

1.Contactless Card Manufacturing

Perfect for embedding antennas in contactless cards used for payments, ID verification, and access control.

2.RFID Card Production

Ideal for producing RFID tags and cards used in logistics, security, asset tracking, and inventory management.

3.Smart Card Production

Excellent for embedding antennas in smart cards utilized in healthcare, finance, public transportation, and more.

4.Antenna Embedding for Inlays

Suitable for any application requiring precise, automated antenna embedding onto plastic inlay sheets.

Why Choose the Auto Antenna Embedding Machine?

1.Superior Quality and Precision

Equipped with ultrasonic embedding technology and a vacuum aspirating platform, this machine guarantees the precise attachment of antennas, ensuring high-quality production with every cycle.

2.Speed and Efficiency

With a speed of up to 400 antennas per hour, the machine significantly enhances throughput, making it ideal for high-volume production environments.

3.Versatility and Customization

Thanks to its PC control system and professional drawing software, this machine is highly adaptable. It supports various antenna shapes, sheet layouts, and materials, ensuring flexibility in meeting diverse production requirements.

4.Reduced Downtime

The dual vacuum platens enable quick material changes without stopping the production process, reducing downtime and improving overall efficiency.

5.User-Friendly Operation

The wide LCD touch screen and intuitive control interface make it easy for operators to manage the machine, adjust settings, and monitor production in real time.

6.Built for High-Volume Production

Designed to handle large-scale production, this machine ensures consistent performance and reliability over extended production runs, minimizing maintenance and maximizing output.

Optimize Your Production Line with the Auto Antenna Embedding Machine

The Auto Antenna Embedding Machine offers a comprehensive solution for embedding antennas onto inlay sheets. Its ultrasonic technology, PC control system, and high-speed operation make it an essential tool for any contactless card, RFID card, or smart card production line. With its precise and efficient embedding capabilities, the machine helps manufacturers achieve high-quality results while increasing productivity and reducing labor costs.

Whether you are producing small batches or scaling up for high-volume production, this machine ensures consistent and reliable performance, making it a critical asset in the competitive world of modern card manufacturing.

Market Applications & Case Studies

1.Contactless Payment Cards

The Auto Antenna Embedding Machine is a crucial tool in the production of contactless payment cards for financial institutions. By embedding antennas with high precision, it enables seamless payment transactions for consumers.

2.RFID Tags for Logistics

The machine is ideal for embedding antennas into RFID tags used in logistics, where tracking and asset management require reliable and durable RFID systems. Manufacturers of these tags benefit from the machine’s high-speed, high-precision capabilities.

3.Smart Cards for Healthcare

In the healthcare industry, the machine is used to embed antennas in smart cards that store patient information, medical history, and other essential data. With precise antenna placement, the cards provide secure and quick access to critical healthcare data.

4.ID and Access Control Cards

The machine plays a key role in the production of ID cards and access control cards used in corporate, government, and secure facility environments. The precise embedding ensures reliable, long-lasting cards for secure entry systems.

Elevate Your Card Manufacturing Line Today!

With its advanced ultrasonic technology, flexible design, and high-speed performance, the Auto Antenna Embedding Machine is the perfect solution for businesses looking to improve their card production processes. Optimize your workflow, enhance product quality, and boost your production capabilities—contact us today to learn more about how the Auto Antenna Embedding Machine can benefit your manufacturing operations.

Leave Your Message

Related PRODUCTS

-

Auto Sheet Trimming Machine - High-Preci

-

Auto Contactless Card Inlay Sheet Manufa

-

Automatic Milling & Implanting Machi

-

Automatic IC Module Implanting Machine

-

Auto Envelope Sealing and Labeling Machi

-

Automatic Module Testing Machine

-

Automatic 3D Curved Antenna Embedding Ma

-

Automatic Frequency Test Machine

-

Auto Wire Embedding Machine (2-in-1 Syst

-

Integrated Inlay Manufacturing System_Ch

Please contact us with your request

We are ready to answer your questions.