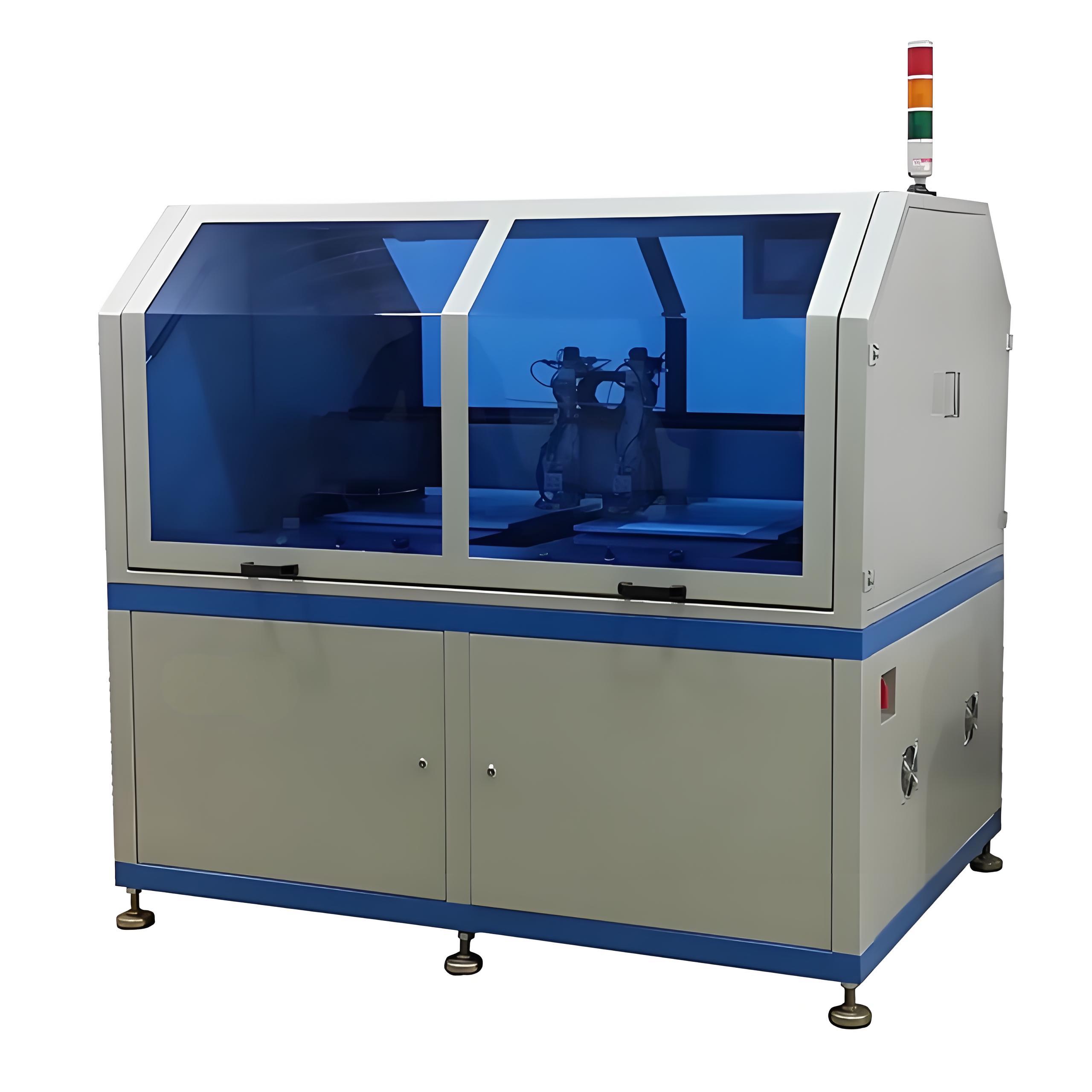

Auto COB Pick and Placer: Revolutionizing Chip Placement in Contactless and Smart Card Production

Auto COB Pick and Placer: Revolutionizing Chip Placement in Contactless and Smart Card Production

As the demand for contactless cards and smart cards continues to rise globally, manufacturers are increasingly seeking innovative solutions to enhance production efficiency and precision. The Auto COB Pick and Placer is an advanced automated machine designed specifically for the RFID and contactless card industry, providing a streamlined, cost-effective, and highly accurate solution for chip placement. By optimizing the process of placing chips onto inlay sheets after antenna embedding, the Auto COB Pick and Placer ensures consistent quality, reduces labor costs, and significantly improves production speed.

With the global expansion of RFID technology and the growing need for smart cards in applications ranging from payments to identification and access control, the Auto COB Pick and Placer is a perfect fit for manufacturers looking to meet high-volume production demands without compromising quality.

Key Features of the Auto COB Pick and Placer

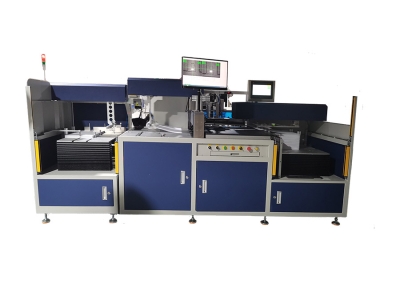

1.High-Precision Vibrating Trays

The machine features high-accuracy vibrating trays that ensure chips are positioned exactly where they need to be for placement. This reduces errors and improves the final product quality.

2.Servo Motor Control for Precision

The servo motor system provides ultra-precise chip placement with a tolerance of ±0.05mm, ensuring high accuracy for every card produced. The system can store multiple programs to accommodate different sheet sizes, making it adaptable to diverse production needs.

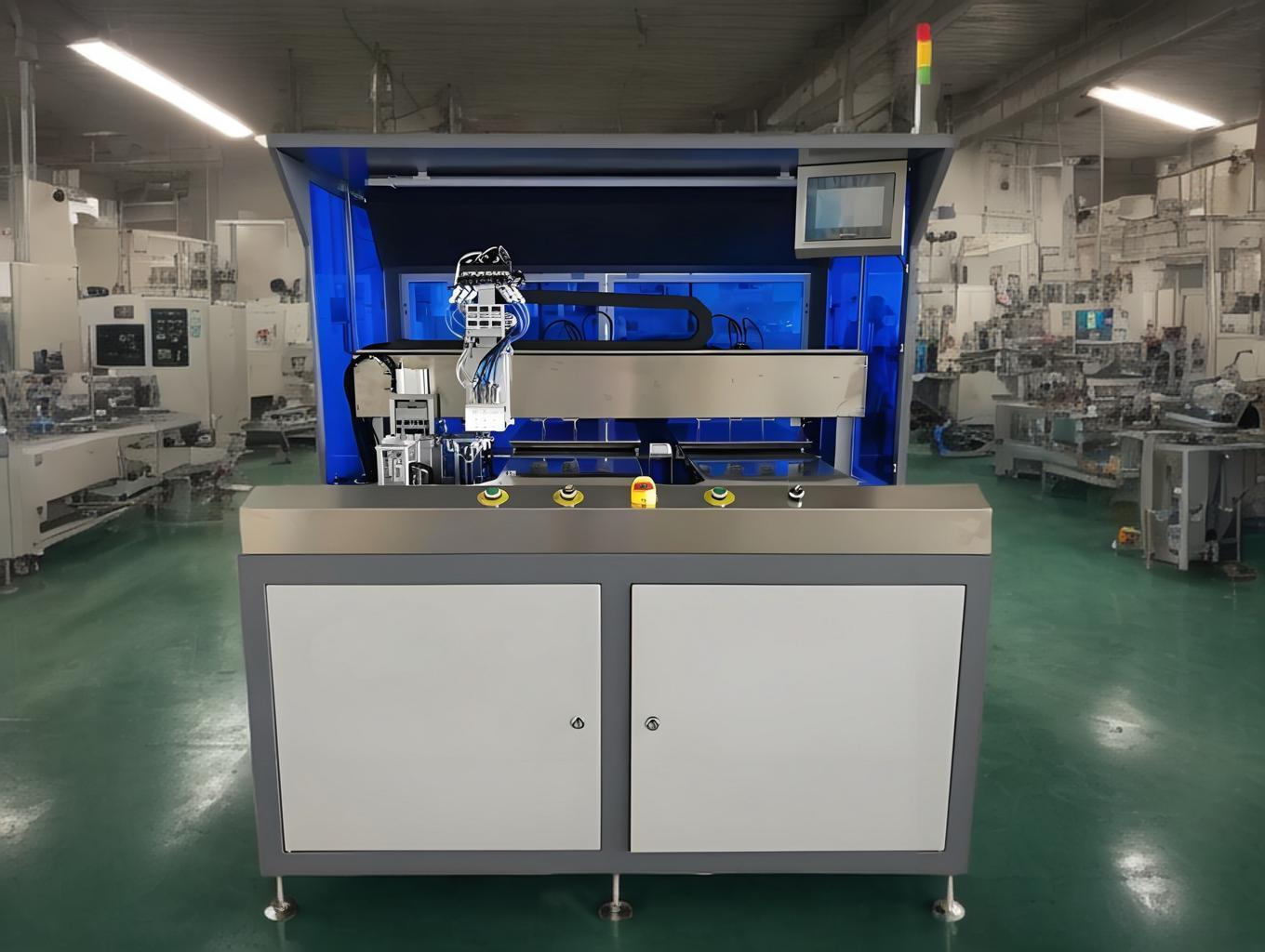

3.PLC Control with Touch Screen Interface

The easy-to-use PLC control system coupled with a touchscreen interface provides intuitive operation, simplifying setup and adjustments for quick changes during production. Operators can easily monitor and control the machine, ensuring smooth operation and efficiency.

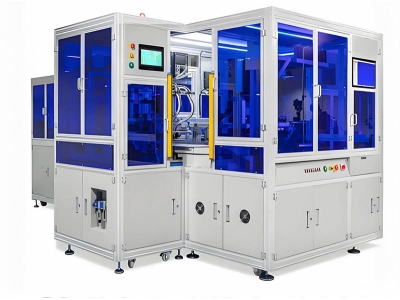

4.Dual Vibrating Trays and Work Tables

With dual vibrating trays and work tables, the machine can operate in a single or dual mode, increasing flexibility and production speed. This configuration enables simultaneous chip placement on both sides of the inlay sheets, doubling throughput and improving efficiency.

5.Easy Setup and Maintenance

The machine is designed for quick setup and minimal downtime, with simple loading processes for inlay sheets and easy-to-maintain components. This ensures long-term reliability and operational efficiency.

6.Stable and Reliable Operation

With its stable performance and well-distributed chip placement, the Auto COB Pick and Placer minimizes defects and ensures high-quality production with every batch.

Machine Specifications

| Parameter | Details |

|---|---|

| Dimensions | L1700 × W1160 × H1600 mm |

| Weight | About 600 kg |

| Sheet Material | PVC, ABS, PETG, etc. |

| Speed | 4,500 cards/hour |

| Power Supply | AC 220V 50/60Hz |

| Compressed Air | 6 kg/cm² |

| Power | 3KW |

| Servo Precision | ±0.05mm |

| Operator | 1 person |

Applications

The Auto COB Pick and Placer is designed to meet the needs of manufacturers across various industries, making it an essential tool for those producing high-volume contactless cards, smart cards, and RFID tags.

1.Contactless Card Production

Perfect for manufacturers producing contactless payment cards, ID verification cards, and access control cards, the Auto COB Pick and Placer ensures precise chip placement, essential for ensuring card reliability and performance in secure environments.

2.Smart Card Manufacturing

Ideal for producing smart cards used in healthcare, finance, public transportation, and security, where precise chip placement is vital to the functionality and security of the card.

3.High-Volume Inlay Sheet Production

With the ability to process up to 4,500 cards per hour, this machine is designed for high-speed, high-volume production, ideal for manufacturers handling large runs of RFID tags and smart cards.

4.Precision Chip Placement for RFID and Smart Tags

Whether you're producing RFID tags for logistics, asset tracking, or inventory management, the Auto COB Pick and Placer ensures every chip is placed accurately and consistently, minimizing defects and enhancing the overall quality of the product.

Why Choose the Auto COB Pick and Placer?

1.Unmatched Precision

The machine's servo motor system guarantees chip placement accuracy of ±0.05mm, ensuring that each card meets the stringent performance standards demanded by the industry.

2.Increased Production Speed

With a speed of 4,500 cards per hour, the Auto COB Pick and Placer significantly enhances the speed of your production line, enabling manufacturers to meet high-volume demands with ease.

3.Flexible Operation

The dual vibrating trays and working tables provide the option to run the machine in single or dual modes, offering flexibility to suit different production needs and increase throughput.

4.Cost-Effective Automation

Automating the chip placement process with the Auto COB Pick and Placer reduces manual labor, cutting down on operational costs while improving efficiency and consistency.

5.User-Friendly Interface

The PLC control system with a touchscreen interface makes operation easy, enabling quick setup, adjustments, and troubleshooting with minimal operator training required.

6.Durable and Reliable

Built with high-quality components, the machine is designed to operate for long periods without compromising on performance, making it a reliable and cost-effective investment for any contactless card or smart card manufacturer.

Market Demand and Trends in Card Manufacturing

The global contactless card market is rapidly growing, driven by increasing adoption in various sectors including banking, retail, transportation, and security. As consumers continue to favor convenient, secure payment methods, the demand for RFID and smart cards is expected to rise significantly.

With this surge in demand, manufacturers must scale production while maintaining high standards of precision and quality. The Auto COB Pick and Placer offers an ideal solution, providing both speed and accuracy to meet the needs of high-volume production environments. It helps manufacturers keep pace with market demand while ensuring product consistency, reducing defects, and cutting costs associated with manual labor.

Optimize Your Production Line with the Auto COB Pick and Placer

The Auto COB Pick and Placer is the ultimate solution for efficient, high-precision chip placement in contactless cards, RFID tags, and smart cards. By improving accuracy, increasing speed, and reducing costs, this machine is a must-have for any manufacturer looking to stay ahead in the competitive card manufacturing market.

Contact us today to learn more about the Auto COB Pick and Placer and how it can help you optimize your production process for contactless and smart cards!