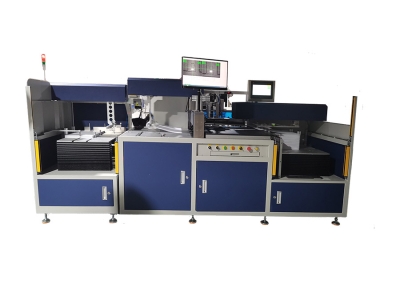

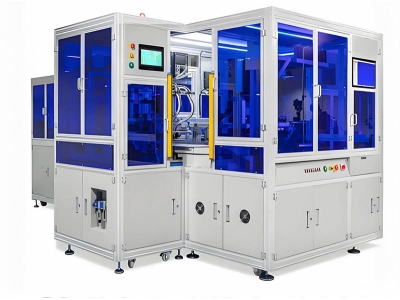

AUTO Bonding Machine – Precision Welding for Smart Card Modules

Overview:

The AUTO Bonding Machine is an advanced automated solution designed for the precise welding of antennas and modules in contactless and smart card production. Whether for RFID, payment cards, or ID cards, this machine ensures high-quality, reliable performance, improving efficiency and consistency in mass production.

Key Features:

1.Automated Control:The machine is controlled by a PLC program, ensuring smooth operation. The user-friendly interface makes it easy to operate and maintain.

2.Dual-Axis Positioning System:Equipped with a dual-axis positioning system, the machine adjusts the X and Y directions of the working platen, allowing precise and automated welding based on preset paths.

3.Adjustable Welding Parameters:Each welding position’s parameters are independently adjustable, offering convenience and flexibility for different production requirements.

4.Advanced Welding Technology:The machine features a double pulse current inverter welding technology that ensures fast, stable operation while maintaining the highest quality standards.

5.Flexible Welding Heads:Equipped with 5 welding heads, the machine can operate with one or all five heads simultaneously, offering great flexibility and increased production efficiency.

6.Versatile Layout Compatibility:The machine supports multiple layout configurations, including 3X8, 4X8, and 5X5, making it adaptable to various sheet sizes and production needs.

Machine Specifications:

| Parameter | Details |

|---|---|

| Dimension | L1300W1100H1600 mm |

| Weight | About 600 kg |

| Power Supply | AC 220V/50Hz |

| Power Consumption | Approx. 5.5KW |

| Compressed Air | 6 kg/cm² |

| Welding Head Lifespan | 20,000~60,000 welding points |

| Control System | Servo System + PLC |

| Material Specifications | PVC, ABS, PET-G |

| Operator | 1 person |

| Output | 1000~1500 pcs/h (single head) |

Industry Applications:

1.Smart Card Manufacturing:Perfect for embedding antennas and welding modules on smart cards used for various applications such as banking, identification, and transportation. The high-speed, high-precision capabilities ensure that production meets demanding quality standards.

2.RFID Card Production:The AUTO Bonding Machine is highly suitable for RFID card manufacturers, providing reliable welding for modules and antennas that are key to the card’s functionality in logistics, asset tracking, and security.

3.Contactless Payment Cards:For manufacturers of contactless payment cards, the machine ensures a secure and precise bond between the antenna and the module, which is crucial for the card's seamless performance.

4.ID and Access Control Cards:Widely used in producing access control cards and ID cards, this machine guarantees a durable connection between components, essential for the functionality of these cards in security and personal identification.

Why Choose the AUTO Bonding Machine?

1.Precision and Efficiency: The dual-axis positioning system and adjustable welding parameters ensure precise and consistent results, while the double pulse current inverter technology maintains high production speeds without compromising quality.

2.High Flexibility: With the ability to operate 1 to 5 welding heads simultaneously, this machine offers flexibility for different production needs, whether it's high-volume or batch production.

3.Increased Productivity: Capable of producing up to 1500 units per hour (per welding head), the machine significantly improves throughput, making it ideal for high-volume production environments.

4.Cost-Effective and Durable: By reducing manual labor and improving consistency, the AUTO Bonding Machine offers an efficient and cost-effective solution with a long lifespan, supporting up to 60,000 welding points per head.

Optimize your production line with the AUTO Bonding Machine. Achieve superior welding quality, increase production efficiency, and reduce labor costs. Contact us today to learn more or request a demo!