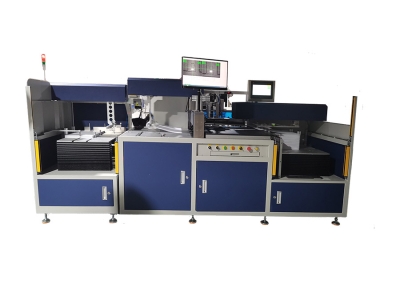

Position Hole Punching Machine - Enhance Your Production Efficiency with Precision

As the demand for contactless cards, RFID cards, and smart cards continues to grow, manufacturers need equipment that can handle high-volume production while ensuring precision and reliability. The Position Hole Punching Machine is designed to meet these demands, offering a highly efficient, precise, and flexible solution for punching positioning and contactless chip fixing holes on INLAY sheets.

Key Features of the Position Hole Punching Machine

1.High-Speed, Simultaneous Hole Punching

The Position Hole Punching Machine is engineered to punch positioning holes and contactless chip fixing holes on INLAY sheets simultaneously. This ensures high-speed processing and high production efficiency, making it ideal for high-volume card manufacturing operations.

2.Precision and Accuracy

The machine delivers accurate hole positioning every time. All the holes are punched at the same time with high precision, minimizing errors and ensuring consistent quality across all units produced. This level of accuracy is crucial for ensuring that the contactless chips are properly placed on the INLAY sheet for optimal performance.

3.Oil Cylinder Punching Power for High Efficiency

Equipped with an oil cylinder as the punching power source, the machine provides large pressure, ensuring that even thicker materials can be punched efficiently. The oil cylinder system also offers easy maintenance, making it an excellent long-term investment for your production line.

4.Multiple Sheet Stacking for Increased Efficiency

The machine can handle multiple stacked INLAY sheets at once, greatly enhancing production efficiency. This feature allows for high-volume production without sacrificing the quality of each hole punched.

5.Simple and Durable Structure

The simple structure of the Position Hole Punching Machine makes it easy to operate and maintain. This not only ensures longer machine life but also minimizes downtime, leading to higher productivity on your production line.

6.Adaptable to Various Material Types

The machine is compatible with a wide range of materials, including PVC and PET (0.2mm to 0.4mm thickness), making it versatile for different types of INLAY sheets used in card manufacturing.

Machine Specifications :

| Parameter | Details |

|---|---|

| Speed | 600 pieces per hour |

| Dimensions | L870 × W550 × H1500 mm |

| Weight | 500 kg |

| Power Supply | AC 360V, 50/60Hz |

| Operator | 1 person |

| Material Specification | 0.2~0.4mm PVC, PET, etc. |

Why Choose the Position Hole Punching Machine?

1.Enhanced Efficiency: With a production rate of 600 pieces per hour, this machine significantly boosts production output, making it ideal for manufacturers with high-volume demands.

2.Precision & Accuracy: The machine’s ability to punch holes with high precision ensures that each INLAY sheet is perfectly aligned, which is crucial for consistent card performance and quality.

3.Cost-Effective Operation: The machine’s oil cylinder punching system provides high efficiency, reducing the need for frequent maintenance and ensuring long-term operational savings.

4.Versatility: Whether you are punching PVC, PET, or other materials, this machine is designed to handle multiple types of INLAY sheets, offering flexibility for various card production needs.

5.Simple Operation & Maintenance: The user-friendly design ensures easy setup and operation, allowing your team to focus on production rather than complicated maintenance procedures.

Applications of the Position Hole Punching Machine:

1.Contactless Card Manufacturing

- Ideal for punching positioning holes and chip fixing holes in contactless cards used for payments, access control, and other applications requiring precise and accurate card construction.

2.RFID Card Production

- Perfect for RFID tags and cards used in logistics, asset tracking, and security, where the accuracy of the punched holes ensures reliable chip attachment and functionality.

3.Smart Card Manufacturing

- Essential for smart card production, this machine enables precise hole punching for applications such as healthcare cards, government-issued identification, and public transportation cards.

4.High-Volume Card Production

- The multi-sheet stacking capability allows manufacturers to significantly increase output without compromising on quality, making it ideal for large-scale card production environments.

Conclusion

The Position Hole Punching Machine is a must-have for manufacturers looking to streamline their contactless card, RFID card, and smart card production processes. With its ability to handle multiple INLAY sheets at once, high-speed punching, and precision in hole positioning, it ensures that your production line runs smoothly and efficiently. By incorporating this machine into your workflow, you can achieve faster production times, reduce costs, and ensure the highest quality for your end products.

For more information on how the Position Hole Punching Machine can improve your manufacturing process, contact us today for a product demo and consultation.