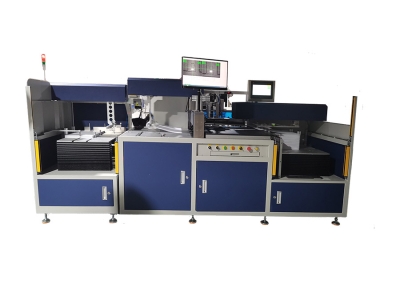

Automatic Multiple Line Welding Machine – Revolutionizing Contactless Card Production

Overview

As the demand for contactless cards continues to grow across industries such as ID cards, residence cards, and transit passes, staying ahead in production efficiency is crucial. Introducing the Automatic Multiple Line Welding Machine, an advanced solution designed to meet the high standards of modern contactless card manufacturing. This innovative machine automates the inlay production process, seamlessly embedding copper antennas and bonding chips onto PVC layers in one continuous, highly efficient workflow.

Equipped with up to 8 ultrasonic embedding heads and a dual-station design, this machine optimizes production, enabling simultaneous antenna embedding and chip bonding to reduce delays and increase throughput. With a remarkable capacity of up to 2,500 inlays per hour, this machine is the ultimate tool for manufacturers aiming to lead the competitive contactless card industry.

Key Features

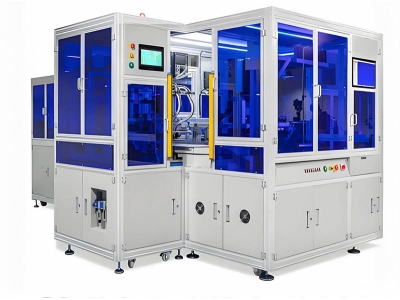

1.Intuitive Operation and Maintenance: Designed for ease of use, this machine requires minimal training for operation and simple upkeep, ensuring smooth production workflows and reduced downtime.

2.State-of-the-Art Ultrasonic Technology: Utilizes advanced ultrasonic embedding technology for consistent, reliable wire placement and high-quality bonding.

3.High-Precision Positioning System: With servo control, the machine ensures precise alignment during both antenna embedding and chip bonding, guaranteeing flawless inlays every time.

4.Smart Automation: Intelligent automation allows for adaptive ultrasonic parameter adjustment, ensuring consistent performance and high production quality.

5.Dual-Station Design: Embedding and bonding processes occur simultaneously, minimizing downtime and significantly increasing overall productivity.

6.Scalable and Versatile: Modular design allows customization for different production needs, supporting a wide range of card types and specifications.

Specifications

| Parameter | Details |

|---|---|

| Machine Dimensions | L1600 × W1150 × H1750 mm |

| Net Weight | Approximately 1,500 kg |

| Production Throughput | 40–60 sheets per hour |

| Power Supply | AC 220V, 50/60Hz |

| Compressed Air | 6 kg/cm² |

| Control System | Four-axis positioning with IPC control |

| Operator Requirement | One person |

Why Choose This Machine?

1.Exceptional Efficiency: With up to 2,500 inlays per hour, this machine reduces production time while maintaining high quality, meeting the growing demand for contactless cards.

2.Consistent Quality: Cutting-edge technologies ensure precise and reliable performance, minimizing errors and defects across large production runs.

3.Cost-Effective Operation: Automation reduces labor costs, while the robust design minimizes maintenance, offering a long-term return on investment.Future-4.Proof Technology: Designed to adapt to evolving market demands, this machine positions your business for long-term success in the competitive contactless card industry.

Applications

1.Next-Generation ID Cards: Ensure high-quality, secure personal identification solutions.

2.Residence Cards: Perfect for embedding contactless technology in residency identification.

3.Transit Passes: Ideal for mass transit systems requiring durable, reliable contactless passes.

4.Membership and Access Control Cards: Enhance security and user experience in membership programs and secure building access systems.

5.Other Contactless Solutions: Suitable for various applications in industries like banking, healthcare, and public services.

Discover the Difference

Boost your contactless card production with the Automatic Multiple Line Welding Machine. Offering high speed, precision, and flexibility, it’s the perfect solution for manufacturers seeking to enhance productivity, improve quality, and stay competitive in the growing market.

Contact Us Today to find out how this machine can optimize your production process and elevate your business in the contactless card industry.