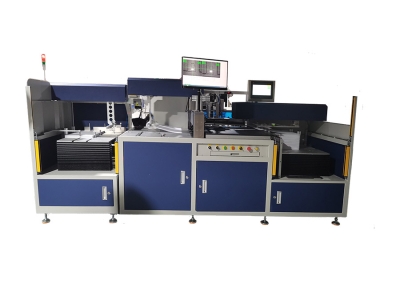

Auto Glue Tape Lamination Machine – Streamlining Chip Lamination for Contactless Card Production

In the fast-paced world of contactless card manufacturing, precision and efficiency are crucial. Introducing the Auto Glue Tape Lamination Machine, an advanced and highly efficient solution designed to streamline the lamination of glue tape for various IC modules. This machine is specifically engineered to meet the growing demand for high-speed, high-precision, and automated production processes in industries such as smart cards, RFID cards, and contactless payment solutions.

Key Features

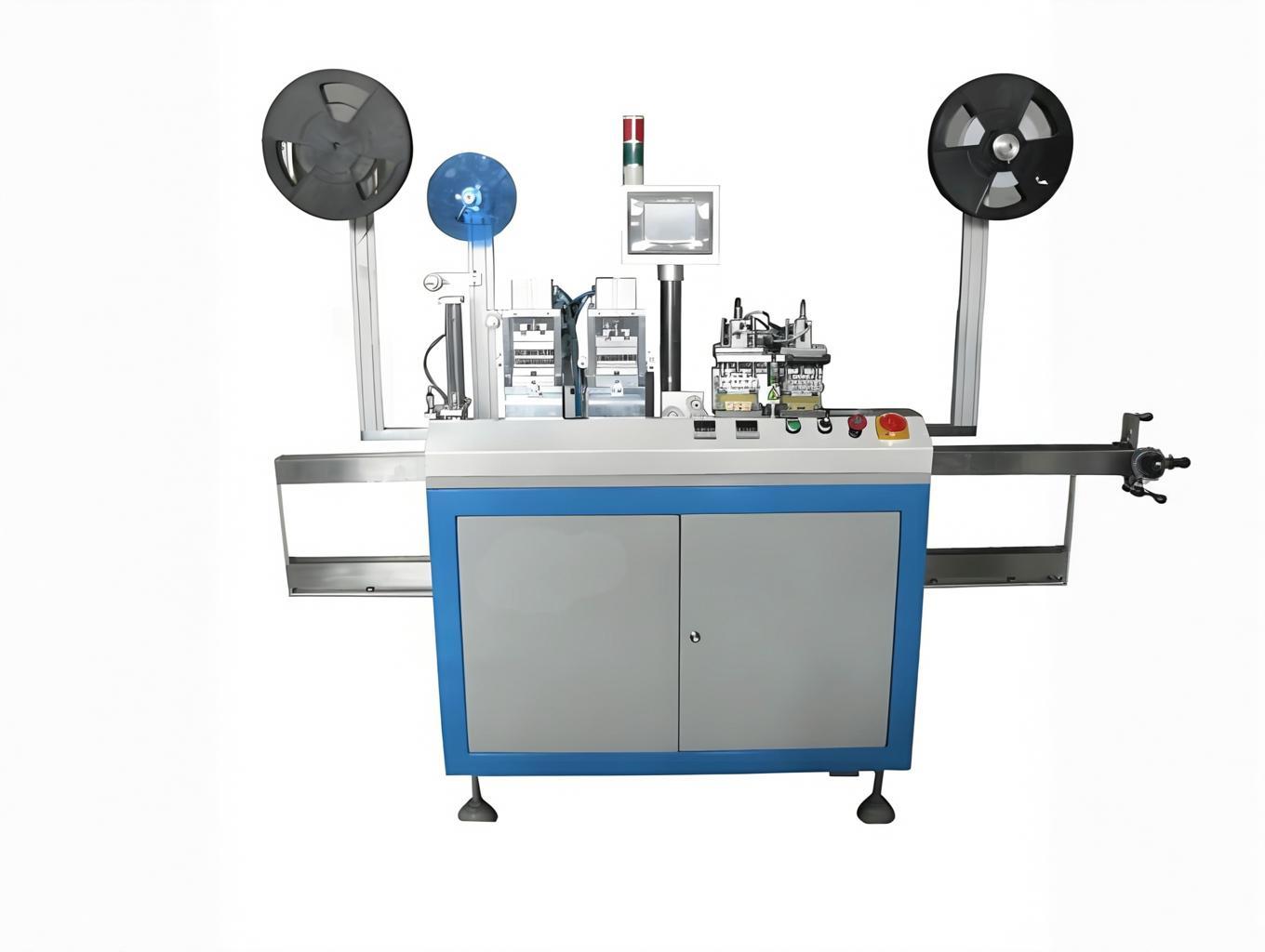

1.Automatic Punching & Cutting: The machine automatically punches and cuts hot melt adhesive tape, ensuring consistent application of glue on different chip models. This feature enhances productivity while maintaining high precision.

2.PLC Control with User-Friendly Interface: Equipped with a PLC program for automatic control and a large touchscreen interface, the machine ensures smooth, stable operation and makes adjustments simple and intuitive. Parameters are fully adjustable, offering full flexibility to suit various production requirements.

3.Servo-Controlled Module Stepping: The servo system controls the module stepping process, enabling precise adjustments to the pulling distance through easily adjustable parameters. An advanced photoelectric sensor monitoring system ensures double protection for the modules, improving reliability.

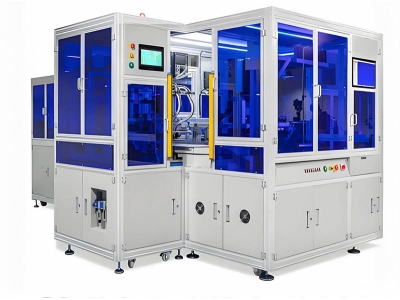

4.Versatile and Flexible Design: The machine combines multiple functions, including IC module stripe lamination, hot melt glue conveyance, rush glue application, hot welding glue lamination, and finished module stripe collection. With its professional design, the machine can seamlessly switch between 6-pin and 8-pin IC module glue tape lamination without needing mold changes, making it highly adaptable to varying production needs.

Machine Specifications

| Specification | Details |

|---|---|

| Machine Dimensions | L1700 × W520 × H1650 mm |

| Weight | Around 300 kg |

| Power Supply | AC 220V 50/60Hz |

| Power Rating | About 1.5 KW |

| Control Mode | PLC + Touchscreen |

| Production Speed | 11,000 – 15,000 chips/hour |

Why Choose the Auto Glue Tape Lamination Machine?

1.High Efficiency: With a production speed of 11,000 to 15,000 chips per hour, this machine significantly boosts your manufacturing capacity, enabling you to keep up with the growing demand for contactless cards and smart card solutions.

2.Easy Operation & Maintenance: The machine is designed for easy operation with a large touchscreen interface. Its simple and intuitive controls make it user-friendly, while the PLC-based system ensures stability and reliability during operation. Maintenance is also straightforward, minimizing downtime and maximizing operational efficiency.

3.Flexibility in Production: Thanks to its advanced design, the machine allows for seamless switching between 6-pin and 8-pin IC module configurations, all through the interface. This flexibility makes it an ideal solution for manufacturers handling multiple card types or those looking to scale their operations.

4.Reliable and Precise: The servo-controlled stepping system ensures the precise adjustment of the pulling distance, while the photoelectric sensors provide additional protection, guaranteeing high-quality, consistent results with every batch.

Applications

The Auto Glue Tape Lamination Machine is an essential tool for manufacturers of:

- Contactless Payment Cards (Credit, Debit, Gift Cards)

- RFID Cards

- Smart Cards (for identification, access control, and other applications)

- Security Cards

Whether you are producing banking cards, ID cards, or membership cards, this machine offers unmatched precision and flexibility, making it a valuable asset for businesses looking to enhance productivity while maintaining high standards of quality.

Upgrade Your Production Process Today

Ready to enhance your chip lamination process? The Auto Glue Tape Lamination Machine is a game-changer for businesses in the contactless card production industry. With its high efficiency, precision, and flexibility, it’s the ideal choice for manufacturers looking to optimize their operations and meet the growing demand for smart cards and contactless payment solutions.