DOD Printing System Proposal: Advanced Smart Card Production Technology

Overview

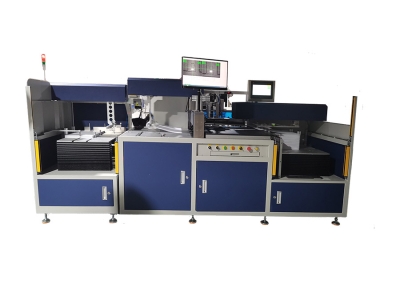

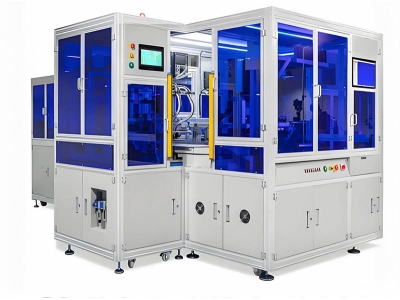

In the rapidly growing smart card and RFID card industry, efficiency, accuracy, and scalability are crucial to staying competitive. The DOD Printing System offers an advanced solution designed for manufacturers of smart cards, RFID cards, and other ISO standard cards. By seamlessly integrating DOD printing, magstripe encoding, contactless card encoding, and labeling, this system transforms the card production process into an efficient, automated, and high-quality operation.

The DOD Printing System is engineered to meet the rigorous standards of industries such as banking, healthcare, government, and security. With a robust vision inspection system that verifies the accuracy of printed data against the database, this system ensures high-quality outputs with minimal errors, making it a must-have tool for manufacturers who need to scale their operations without compromising on quality.

Key Features of the DOD Printing System

1.Comprehensive Integration for Seamless Production

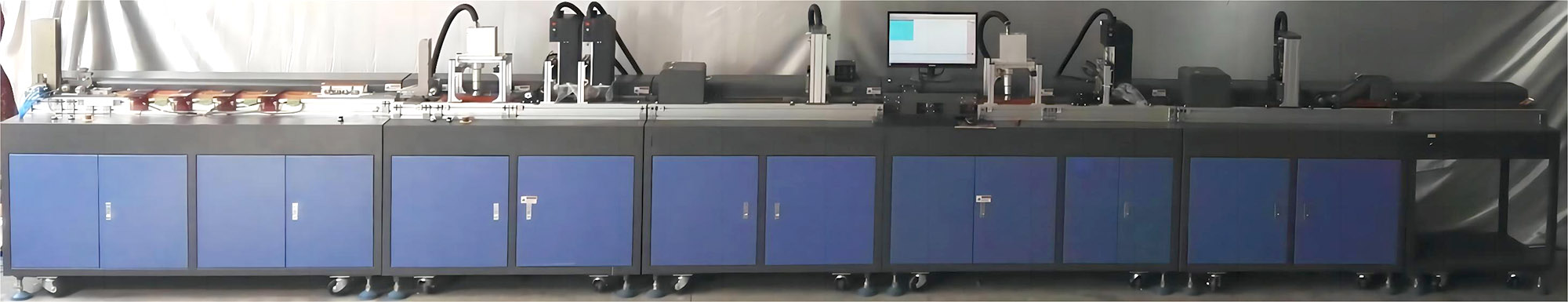

- The DOD Printing System combines multiple processes in one machine, including DOD printing, magstripe encoding, contactless encoding, and labeling. This integration reduces manual handling, accelerates production, and increases efficiency.

- The system also includes a vision inspection unit, which ensures that all printed data aligns perfectly with the data stored in the database. This feature guarantees that the final product is accurate and error-free.

2.Magstripe Encoding with Quality Control

- The magstripe encoder supports 1, 2, and 3 tracks and provides both writing and reading functions. If the writing process is not successful, the system will automatically reject the card, ensuring that only correctly encoded cards proceed through the production line.

- The system can also link the printed data with the magnetic stripe data, ensuring that the card's printed information matches its encoded data.

3.Advanced Contactless Card Encoding

- The contactless card encoder is compatible with ISO 14443 Type A and Type B chips, as well as ISO 16593 chips, making it versatile for a wide range of card applications. It can write data in decimal, hexadecimal, or ASCII formats, and supports up to 4 blocks of encoding per pass.

- This feature is ideal for producing contactless payment cards, access control cards, and other contactless RFID cards used in various industries.

4.High-Precision DOD Printing

- The system uses high-precision Japanese DOD printer nozzles, known for their long lifespan and high-quality performance. With a printing resolution of 360 DPI vertically and 720 DPI horizontally, the system can produce detailed barcodes, 2D codes, text, logos, and images with incredible accuracy.

- Printing materials supported by the system include PVC, PET, PETG, and PP, ensuring compatibility with a wide variety of card types.

5.Automated Vision Inspection

- The vision inspection unit ensures that all cards are printed correctly by comparing the printed data with the database. If the data does not match, the system automatically rejects the card, ensuring that only correct and valid cards move forward in the production line.

- This inspection system ensures 100% quality control of each card, minimizing defects and reducing waste.

6.Efficient Labeling and Laser Printing

- The labeling unit features a servo motor control system and high-accuracy sensors, which guarantee precise and accurate label placement on each card. The adjustable labeling width allows flexibility for different card sizes.

- The laser unit can be used for variable data printing, including text, barcodes, 2D codes, and images. With a speed of ≥6K PCS/hour, it’s perfect for adding custom logos or specific identifiers to cards in high volumes.

7.Data Management Software for Control and Adjustment

- The system includes advanced data management software that allows operators to easily control the printing, encoding, and labeling processes. The software ensures that all data is in order and allows for real-time adjustments to optimize production flow.

- The software also records rejected cards in the system, allowing them to be remade during the next production run, minimizing waste and maximizing efficiency.

8.High-Speed, High-Volume Production

Capable of printing, encoding, and labeling up to 10,000 cards per hour, the DOD Printing System is perfect for high-volume production environments. Whether you're producing smart cards, contactless cards, payment cards, or access control cards, this system ensures fast throughput while maintaining top-tier print and encoding quality.

Key Components and Specifications

| Part | Function & Details |

|---|---|

| DOD Printing | Prints barcodes, 2D codes, logos, text, and images on cards. Printing speed: 20 meters/min. Resolution: 360 DPI (vertical), 720 DPI (horizontal). Material: PVC, PET, PP. |

| Magnetic Encoder | Supports 1, 2, and 3 tracks. Writing and reading modules for error detection. Speed: 6K PCS/hour. |

| Contactless Encoder | Supports ISO 14443 A/B and ISO 16593 chips. Encoding speed: 3000-4000 PCS/hour. |

| Vision Inspection Unit | Verifies printing data accuracy against the database. Rejects unrecognized cards. Speed: ≥10K PCS/hour. |

| Labeling Unit | High-accuracy labeling system with adjustable width. Speed: ≥10K PCS/hour. |

| Laser Unit | CO2 laser system for variable data printing. Speed: ≥6K PCS/hour. |

Industry Applications

1.Smart Cards and RFID Cards

- The DOD Printing System is ideal for manufacturers of ID cards, banking cards, credit cards, membership cards, and access control cards. Its high-speed production capabilities make it ideal for large-scale card manufacturing operations, while its ability to encode magstripes and contactless chips ensures compatibility with various card applications.

2.Healthcare and Pharmaceutical Cards

- In healthcare, the system can be used to produce patient ID cards, medical insurance cards, and regulatory compliance cards. It can print barcodes, QR codes, and serial numbers for quick access to patient information, enhancing efficiency in medical environments.

3.Government and Security Applications

- For government agencies and security firms, the DOD Printing System can produce national ID cards, driver’s licenses, passports, and access control badges. The system’s vision inspection ensures that each card contains accurate, high-quality data, critical for security purposes.

4.Transport and Ticketing

The system is perfect for printing transit passes, event tickets, contactless smart tickets, and membership cards for public transport systems, stadiums, and clubs. The system can print and encode essential information such as barcode data, RFID chips, and customer identification.

Why Choose the DOD Printing System?

1.High Efficiency: Capable of producing up to 10,000 cards per hour, the system can handle large-scale production while maintaining high standards of quality and accuracy.

2.Precision and Quality Control: The combination of advanced DOD printing, contactless encoding, and vision inspection ensures that every card meets the highest standards of accuracy and reliability.

3.Cost-Effective: The automation of the production process reduces labor costs and minimizes the risk of human error, helping businesses save time and money.4.Versatility: With compatibility for a wide range of card types and encoding formats, the DOD Printing System is adaptable to various industries, including banking, healthcare, government, and transport.5.Easy Integration: The system integrates smoothly into existing production lines, and the user-friendly software makes it easy to manage and adjust production settings.