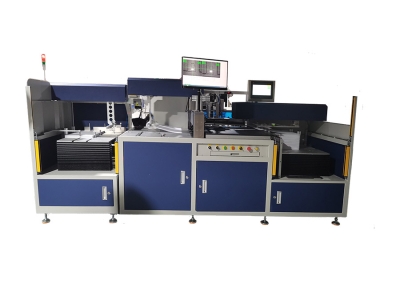

Manual IC Module Punching Machine

Streamline Your IC Module Production with the Manual IC Module Punching Machine

Introducing the Manual IC Module Punching Machine from Shenzhen Zowinda Technology Co., Ltd., a robust and efficient solution designed for manual cutting of IC chips from various IC module tapes after the application of hot melt glue. This machine delivers precision and reliability, ensuring high-quality results for your manufacturing process. With its simple structure, user-friendly operation, and versatile features, it’s the perfect choice for enhancing your production efficiency.

Key Features:

1.Precise Manual IC Chip Cutting

The Manual IC Module Punching Machine is engineered for the precise and efficient cutting of single IC chips from various IC module tapes. After the hot melt glue is pressed onto the IC module’s bottom side, the machine accurately cuts and separates the modules for further processing.

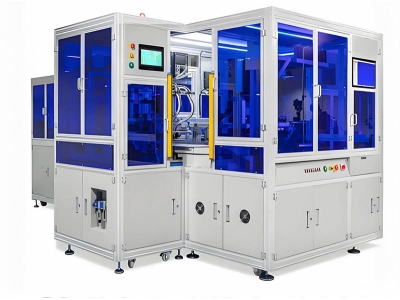

2.Simplicity in Design and Operation

With its simple structure, the machine is easy to operate and maintain, ensuring long-term reliability. The intuitive design allows operators to work with ease, reducing the chances of errors and improving overall production efficiency.

3.Stable and Safe Performance

The machine operates smoothly and safely, with all processes controlled by a single operator. Its consistent performance ensures minimal downtime and high operational reliability.

4.Adjustable Hot Melt Glue Settings

The machine allows for full control over the temperature, time, and pressure of the hot melt glue, enabling optimal adhesive application and IC chip separation based on specific production requirements.

5.Convenient Finished Product Collection

Equipped with a finished product collection device, the machine simplifies the collection and adjustment of the completed IC chips. This feature helps improve workflow efficiency, making it easier for operators to manage and prepare products for subsequent processes.

Why Choose the Manual IC Module Punching Machine?

- Enhanced Production Efficiency: With its user-friendly interface and adjustable settings, this machine can significantly improve your production speed and accuracy.

- Easy Operation: The machine is designed for one-person operation, ensuring cost-effective use of labor while maximizing output.

- Long-Term Durability: Built with high-quality components and designed for easy maintenance, this machine guarantees longevity and consistent performance.

Industry Application Case:

The Manual IC Module Punching Machine is ideal for businesses in the electronics manufacturing industry that require precise cutting of IC chips. For instance, a company specializing in RFID and smart card production can use this machine to efficiently cut IC modules after applying hot melt glue, ensuring that each chip is perfectly separated and ready for the next stage of production. With adjustable settings, it provides flexibility for manufacturers to optimize their processes based on the specific requirements of different IC module tapes.