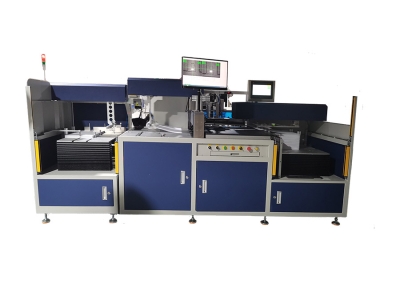

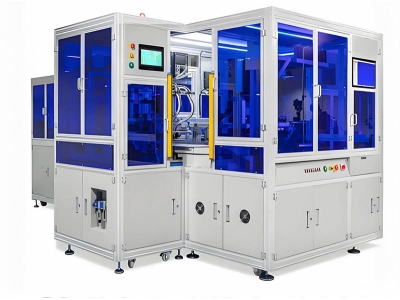

Product Webpage Promotion Copy: Sheet Positioning and Bonding and Collating Machine (Sheets Welding Machine)

Maximize Precision and Efficiency with the Sheet Positioning and Bonding and Collating Machine

The Sheet Positioning and Bonding and Collating Machine from Shenzhen Zowinda Technology Co., Ltd. is designed to streamline the process of multilayer card sheet welding, offering exceptional accuracy and efficiency in industrial applications. Whether you're in electronics manufacturing, card production, or other related fields, this machine offers reliable performance, easy control, and versatile functionality to meet your production needs.

Key Features:

1.Reliable Relay Control System

The machine is equipped with a relay-based control system, ensuring reliable operation with stable performance over extended use. This system guarantees the precise timing and temperature control necessary for effective welding.

2.Imported Temperature Control Instruments

To ensure optimal welding quality, the machine uses high-quality imported temperature control instruments. This feature ensures accurate and consistent temperature regulation, improving the quality of the welding process and extending the machine’s lifespan.

3.Time Relay-Controlled Welding Process

The welding process is controlled by time relays, allowing precise regulation of the welding time to ensure that each sheet is welded to perfection. This helps in reducing errors and enhances the overall reliability of the production line.

4.Precise Contraposition Welding for Multilayer Cards

This machine is specifically designed for contraposition welding of multilayer card sheets. It offers precise alignment for each sheet, ensuring that each layer is bonded accurately, making it ideal for multilayer card and smart card production.

5.High Throughput and Efficiency

Capable of processing up to 200–400 sheets per hour, the machine ensures high throughput and efficiency in card sheet welding. This makes it an excellent choice for manufacturers looking to boost productivity while maintaining high quality standards.

Why Choose the Sheet Positioning and Bonding and Collating Machine?

- Enhanced Precision: The relay control system combined with imported temperature control instruments ensures precise welding for multilayer card sheets.

- Efficient Operation: The machine’s fast throughput of 200–400 pcs/hour makes it ideal for high-volume production environments.

- Durable and Reliable: Designed with a focus on longevity, the machine provides stable and consistent performance, making it a cost-effective investment for your production line.

Industry Application Case:

The Sheet Positioning and Bonding and Collating Machine is ideal for manufacturers in the smart card and RFID industries. For instance, a company producing multilayer RFID cards can use this machine to precisely weld the various layers of the card sheets, ensuring that each layer aligns perfectly for high-quality card production. The machine’s flexible design accommodates various sheet layouts, making it adaptable to different production needs.