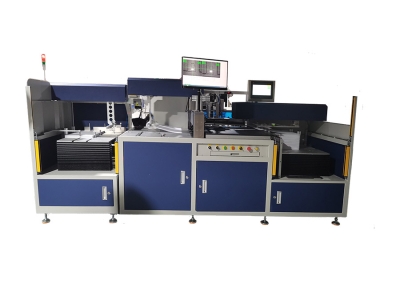

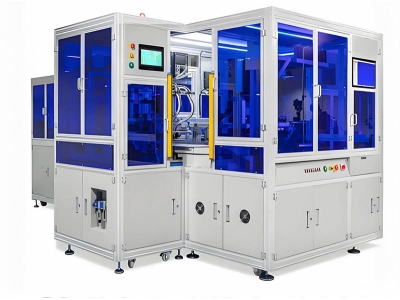

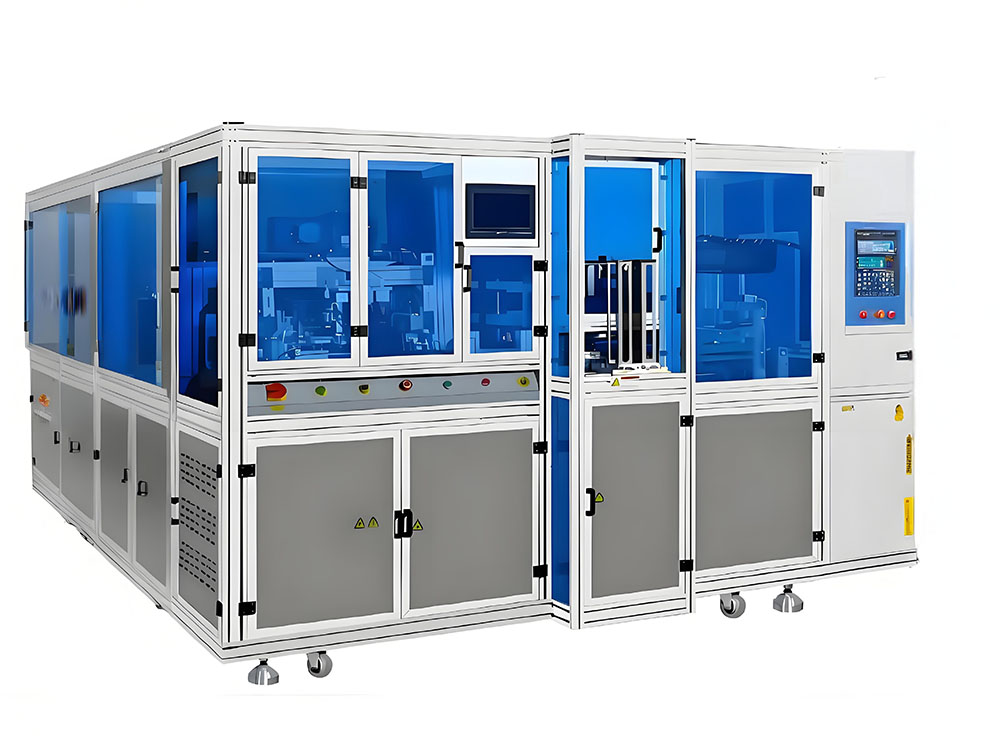

Unlock Precision and Efficiency with the Automatic Card Punching Machine

Shenzhen Zowinda Technology Co., Ltd. proudly presents its Automatic Card Punching Machine, a state-of-the-art, all-in-one solution designed to streamline the production process of high-end cards. With advanced PLC control, this machine integrates automatic feeding, sheet collating, sensor positioning, servo punching, and scrap collection—all in a single, highly efficient system. Perfectly suited for bank card and other high-precision card production, it ensures superior performance, precision, and high throughput for manufacturers in the card industry.

Key Features:

1.Precise and Powerful Punching for Premium Cards

The machine is engineered to perform flawless punching on ABS and PC cards using a specialized mold, making it the ideal solution for producing high-end, special material cards. Whether for bank cards or other high-precision applications, this machine guarantees smooth, accurate cuts every time.

2.High Sensitivity Positioning for Accurate Punching

The high-sensitivity photoelectric sensor, in combination with an imported servo system, ensures that material feeding is precise and punch locations are adjustable with high accuracy. With punching precision of ±0.03mm, this machine delivers superior results consistently.

3.Long-Lasting Precision with Servo Motor and Ball Screw

The use of an imported ball screw module and servo motor guarantees accurate step feeding, reducing wear and tear and extending the machine’s operating life. This setup ensures a smooth, continuous operation and precise positioning with every punch.

4.High-Power Punching for Smooth Edges

The large torque servo used as the punching power source delivers high speed and strong force, ensuring smooth edges on each card and minimizing material deformation. Whether dealing with PVC, PET, or PETG, the result is a clean, flawless cut.

5.Efficient Sheet Loading and Sequenced Card Collection

Equipped with an automatic sheet loading unit, the machine quickly and efficiently loads large PVC sheets onto the punching platform. The collating mechanism then ensures that cards are collected in sequential order, making the machine ideal for personalized card collection.

6.Convenient Card Box System

Featuring a double card box system, each box has a capacity to hold 500 standard cards. The boxes can be easily swapped without stopping the machine, making it a highly efficient solution for continuous production. The easy removal and installation process further enhance operational convenience.

Why Choose Shenzhen Zowinda Technology Co., Ltd.?

At Shenzhen Zowinda Technology Co., Ltd., we specialize in delivering cutting-edge automation solutions designed to meet the evolving needs of the card manufacturing industry. With our Automatic Card Punching Machine, you can enhance your production capacity, ensure precise card punching, and streamline your operations to meet high-volume demands.

Technical Specifications:

| Specification | Details |

|---|---|

| Voltage | 380V 50HZ |

| Power | 9.5KW |

| Air Source | Over 6kg/cm² |

| Gas Consumption | 40L/min |

| Layouts | 3×8, 4×8, 5×5, etc. |

| Control Method | PLC + Servo System |

| Output | 18,000–30,000 PCS/h |

| Punching Precision | ±0.03mm |

| Materials | PVC, PET, PETG, paper, mixed materials |

| Dimensions | L2450×W1650×H1900mm |

Industry Applications:

This Automatic Card Punching Machine is ideal for use in the production of high-end cards including:

- Bank Cards: Perfect for precise, high-speed punching of bank cards and financial cards.

- ID Cards: Suitable for producing ID cards, membership cards, and RFID cards.

- Gift Cards & Loyalty Cards: Optimized for efficient production of gift cards, loyalty cards, and other promotional cards.

Smart Cards: Ideal for punching smart cards and chip cards used in various industries.

Why Invest in the Automatic Card Punching Machine?

For businesses looking to boost efficiency, enhance quality, and scale their operations, the Automatic Card Punching Machine from Shenzhen Zowinda Technology Co., Ltd. is the perfect solution. With its robust features, cutting-edge technology, and reliable performance, this machine is your key to staying ahead in the competitive card manufacturing market.