Revolutionizing Card Production with Automatic Sheet Collating and Overlay Machine

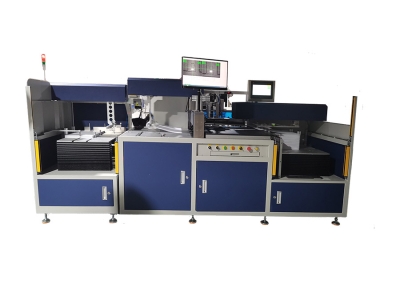

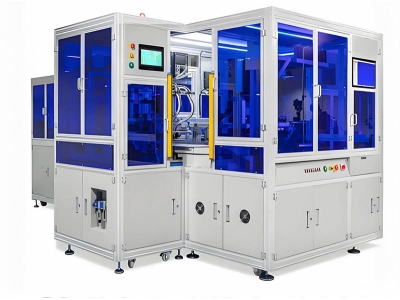

Shenzhen Zowinda Technology Co., Ltd. is proud to introduce its Automatic Sheet Collating and Overlay Machine, designed to meet the high-precision demands of modern card-based production. This cutting-edge equipment integrates a wide array of advanced technologies to streamline the card production process, enhancing speed, accuracy, and overall efficiency.

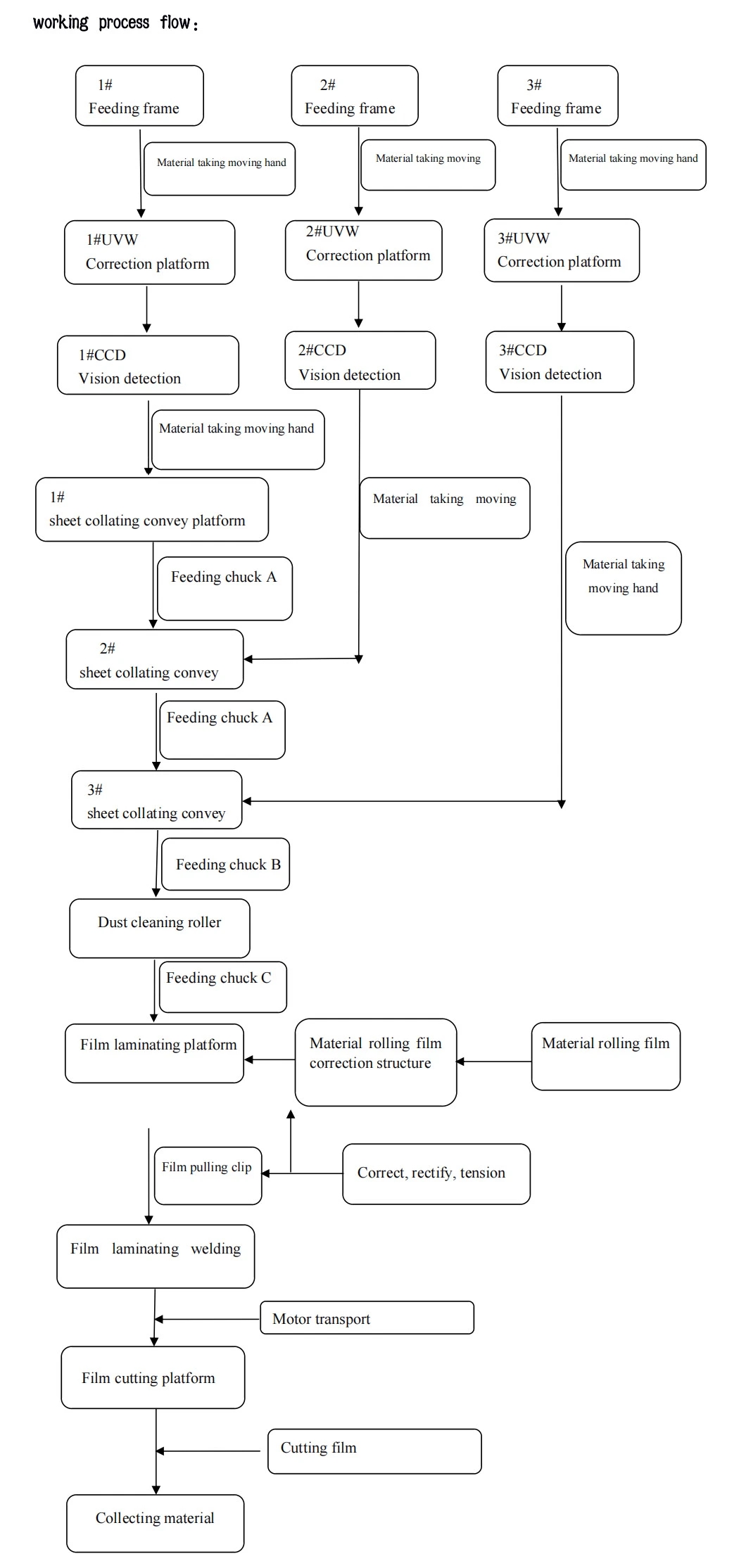

The machine automates several critical steps, including sheet loading, sheet collating, overlay laminating, ultrasonic welding, material correction, and card cutting. With an emphasis on precision and automation, this machine is perfect for high-end card manufacturing operations requiring consistent output and high-quality results.

Key Features

1.Automatic PVC Sheet Loading and Collating

- Three sets of automatic sheet collating feeding frames are equipped with gear motor-driven platforms for seamless material loading and sheet separation.

- The UVW correction platform uses high-precision cross roller platforms and step motors for X and Y-direction correction of each PVC sheet to ensure exact material alignment during the sheet collating process.

2.Advanced CCD Vision and Color Code Detection

- A CCD vision system integrated with a color code magic eye detects and corrects any misalignment in the PVC material, providing real-time feedback to the UVW correction platform. This ensures all materials are perfectly aligned before further processing.

3.Precision Welding and Laminating

- The machine features ultrasonic welding technology for precise material bonding. The film laminating platform uses ultrasonic heads to perform spot welding, ensuring strong and accurate lamination for each card layer.

- An automatic film cutting mechanism, driven by servo motors, ensures the overlay film is precisely cut after lamination, with the finished material sent to the designated collection area.

4.Dust Removal and Material Correction

- Equipped with a sticky dust roller, the machine efficiently removes any dust from PVC sheets before the collating and film laminating process. This guarantees clean materials for optimal bonding and welding results.

5.High Precision and High Efficiency

- The machine operates with collating accuracy of ±0.1mm, and it can produce between 700-900 finished cards per hour, making it ideal for large-scale production environments.

6.Robust Control and Feedback System

- The system is controlled by a servo motor-driven system, ensuring smooth and precise operation. The combination of CCD visual positioning and automated feedback loops guarantees that the system adapts to any variations in material position, providing stable, high-quality production results.

7.Customized Configurations

The machine supports various card formats, including 3x8, 4x8, and 5x5, making it adaptable to diverse production requirements

Main Applications

- Bank Cards: Perfect for bank card production, ensuring precise lamination and cutting for high-quality personalized cards.

- ID Cards: Ideal for government and security card production, where precise lamination and alignment are critical for card integrity.

- Gift Cards & Membership Cards: Suited for high-volume, personalized gift card or membership card production, ensuring efficient and clean results.

- Smart Cards: Supports advanced card manufacturing, including RFID and contactless cards, with high precision and fast production speed.

Main Technical Specifications

| Parameter | Specification |

|---|---|

| Control Method | Servo system |

| Positioning | CCD Vision System |

| Output Voltage | AC380V 50/60Hz |

| Air Source | 6 Kg/cm² |

| Output | 700-900 cards/hour |

| Power | 8KW (Estimated) |

| Collating Accuracy | ±0.1mm |

| Supported Formats | 3x8, 4x8 |

| Machine Dimensions | L3700 * W3200 * H1900 mm |

| Machine Weight | Approx. 6000 KG |

Enhance Production Efficiency with Shenzhen Zowinda

The Automatic Sheet Collating and Overlay Machine is designed for card manufacturers looking to boost their productivity while ensuring high precision and reliability in their operations. Whether you are producing PVC, PETG, or paper cards, this machine offers a seamless solution for card collating, laminating, welding, and cutting, making it the ultimate tool for modern card production lines.