Smart Card Inspection System - Advanced Vision-Based Quality Control for Card Manufacturing

Overview:The Smart Card Inspection System is a state-of-the-art, fully automated visual inspection solution for plastic and smart cards. Integrating cutting-edge optics, electro-mechanics, and computer software technologies, this system ensures high-quality standards in card production by detecting defects and verifying printed characters using Optical Character Recognition (OCR). The WJ-18000 model has become a crucial tool in the card manufacturing industry, helping businesses maintain stringent quality control while reducing labor costs.

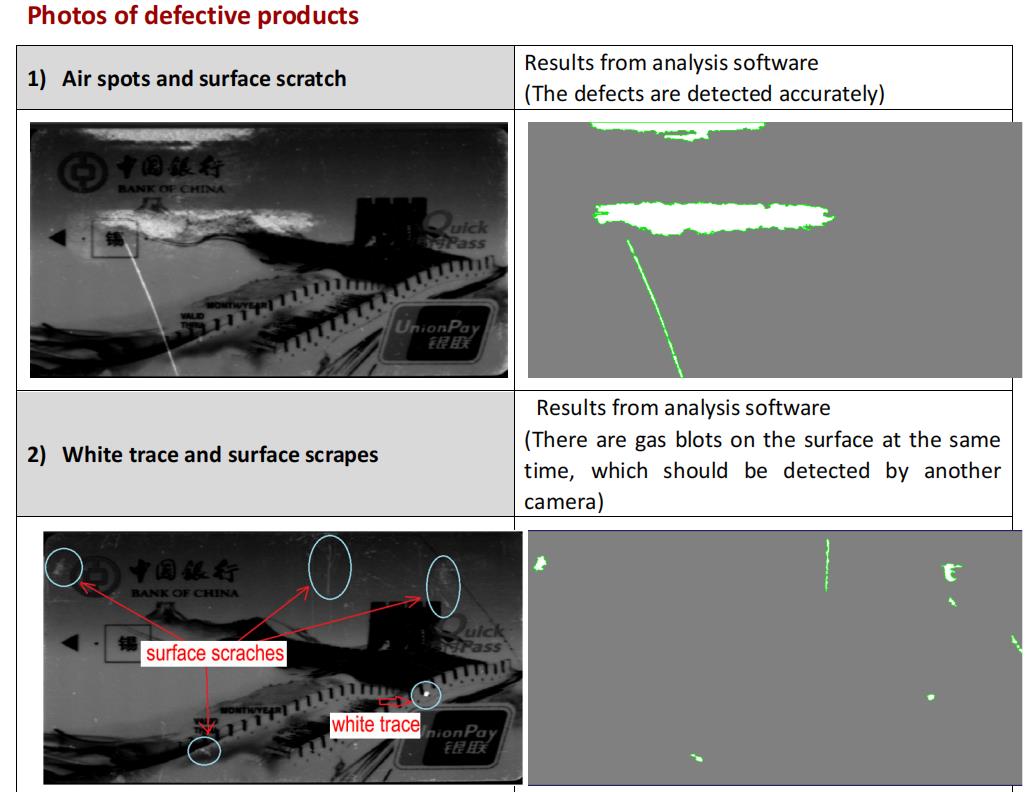

By leveraging advanced vision inspection principles, the Smart Card Inspection System provides thorough defect detection on both sides of cards, offering unparalleled accuracy, stability, and convenience. It guarantees the identification of defects such as ink spots, scratches, lamination issues, and misaligned features like magnetic stripes and holograms, ensuring that each card meets the highest quality standards.

Key Features:

- Automatic Visual Inspection: Detects common card defects like ink spots, scratches, air bubbles, missing letters, and more.

- High-Speed Performance: Capable of inspecting up to 18,000 cards per hour, significantly improving production efficiency.

- OCR Integration: Optical Character Recognition ensures accurate identification of printed characters, maintaining high precision.

- Versatile Applications: Ideal for SIM card, banking card, plastic card, and tag manufacturers, as well as card personalization bureaus.

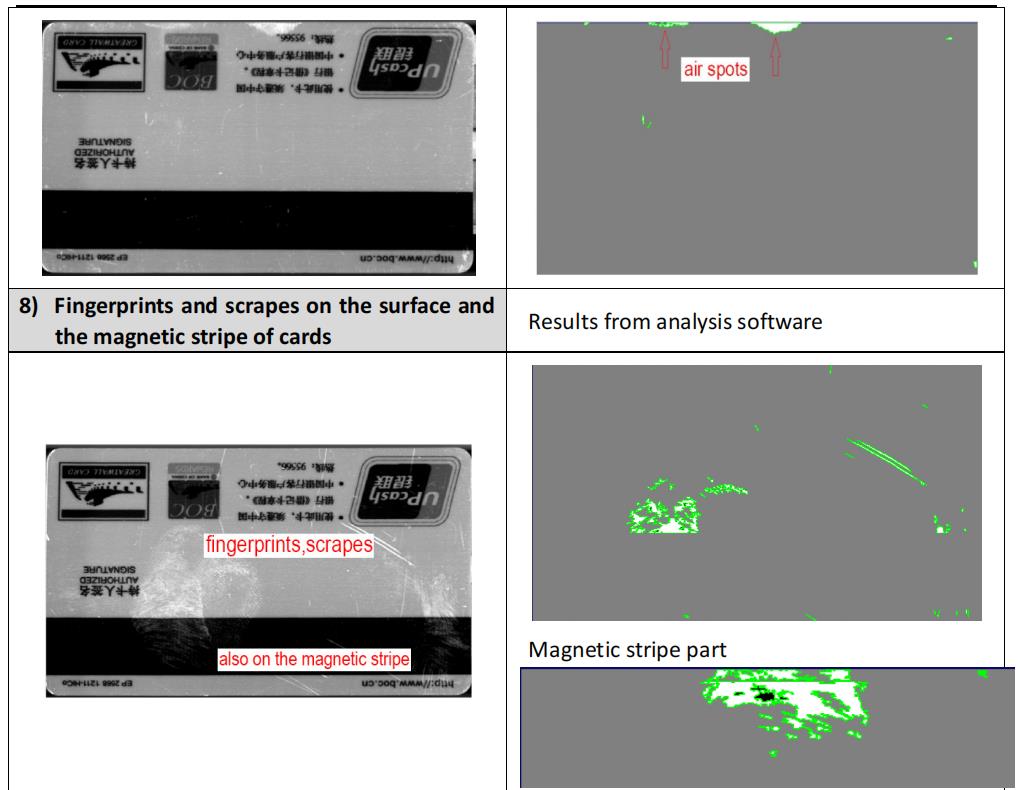

- Comprehensive Defect Detection: Inspects various elements including holograms, magnetic stripe positions, signature placement, and lamination quality.

- Reduced Labor Costs: Replaces manual inspection, minimizing human error and enhancing the reliability of quality control processes.

- Stable and Reliable: Operates efficiently in diverse environmental conditions with a wide temperature and humidity tolerance.

Applications:

- SIM/Banking Card Manufacturers

- Plastic Card/Tag Manufacturers

Card Personalization Bureaus

Typical Inspection Items:

- Ink Spots

- Air Bubbles

- Missing Letters

- Surface Scratches

- Laminated Scratches

- Lamination Dirty Spots

- Blebs and Enclosures

- Signature Position

- Magnetic Stripe Position

- Hologram Position and Defects

- Partial Missing Lamination Foil or Holes

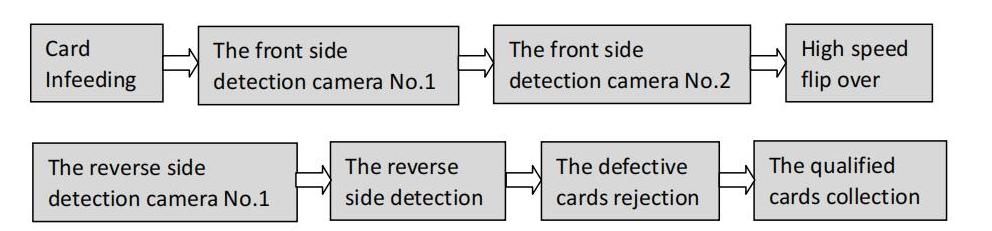

Full Auto Card Surface Detection Machine (Detection Module) External Detection Module Introduction

The test can be accomplished at once as a result of detecting the both sides concurrently with four cameras working online.

Working Flow

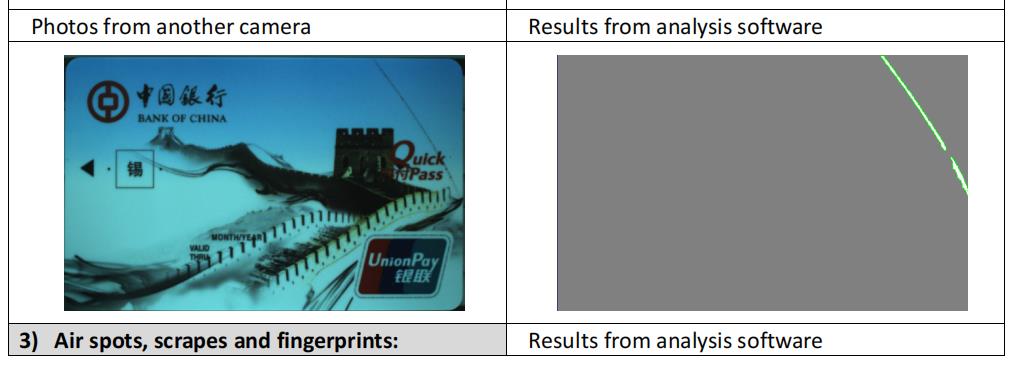

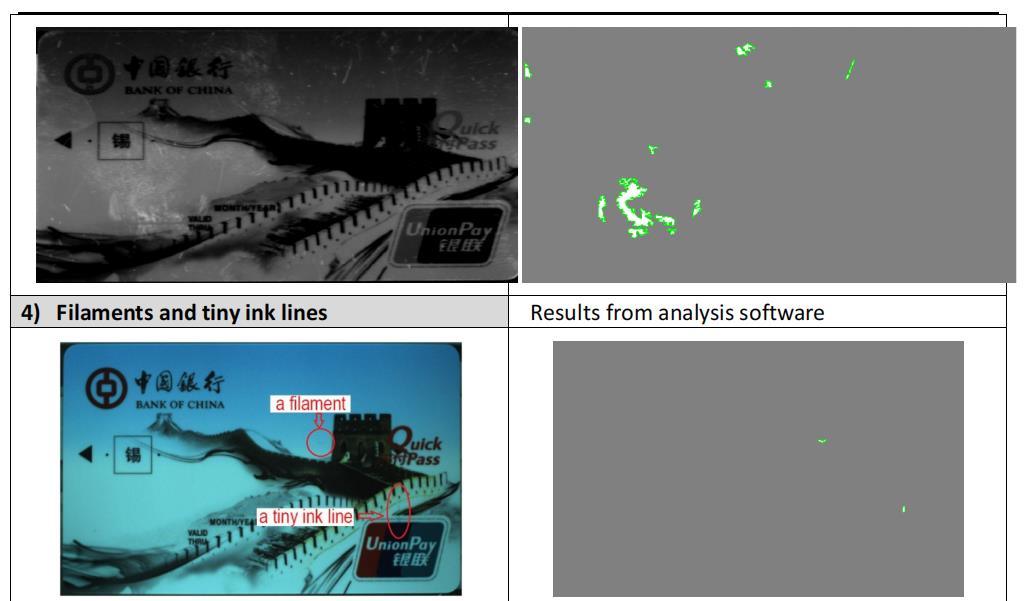

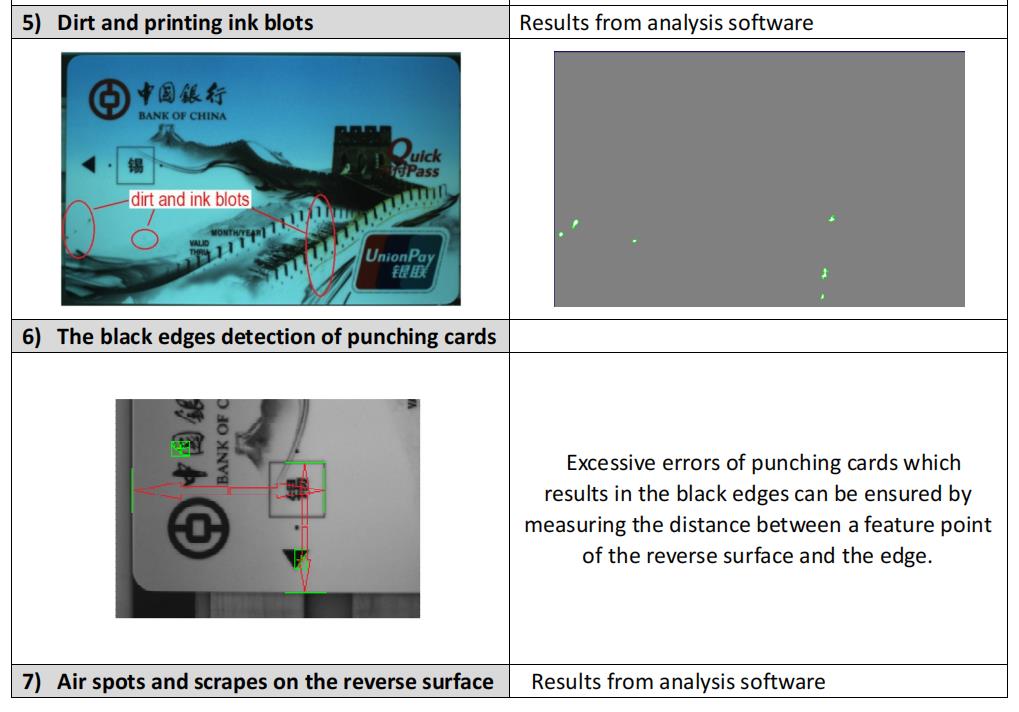

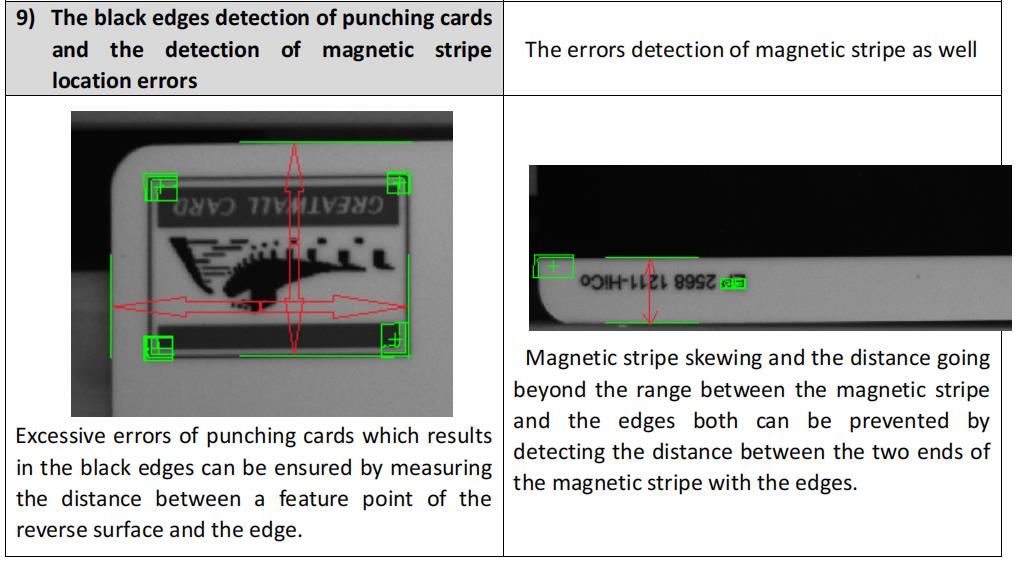

Defects can be detected: Surface scratching, laminated watermark, air spots, bubbles, gas blots, punching errors (black edges), unclear print, fringe, watermarks, etc.

Location of the card LOGO, Union Pay sign, VISA sign, magnetic stripe, signature panel, etc. And the detection of the external dimension.

Technical Parameters:

1.Inspection Speed: 18,000 cards per hour (speed may vary depending on inspection items and requirements)- Operating Environment:

- Temperature: 5~40℃

- Humidity: 15~90%

- Storage Temperature: -10~60℃

- Air Pressure: 0.45-1 MPA

- Air Flow: ≥20L/min

- Air Supply Distance: ≤3.5 meters from the machine

- Power Supply: 220V±10%, 48~62Hz

- Power: 1.6KW (Independent power outlet required)

- Grounding Resistance: <10Ω

- Required Electrical Outlet: Standard triple power outlet, current ≥10A

- Mainframe: 2540(L) * 710(W) * 1500(H)

- Issuing Part: 1400(L) * 710(W) * 1500(H)

- Collecting Part: 1500(L) * 710(W) * 1500(H)